4 Axle Dump Truck Capacity: A Comprehensive Guide

4 Axle Dump Truck Capacity: A Comprehensive Guide cars.truckstrend.com

In the demanding world of construction, mining, and bulk material transport, dump trucks are the undisputed workhorses. Among the various configurations, the 4-axle dump truck stands out as a versatile and powerful machine, striking an optimal balance between payload capacity, maneuverability, and legal compliance. Understanding its capacity is not just about knowing how much dirt it can haul; it’s about optimizing operational efficiency, ensuring safety, and adhering to strict regulations.

This comprehensive guide delves deep into the multifaceted concept of 4-axle dump truck capacity, exploring what it means, why it matters, and how to leverage it for maximum productivity.

4 Axle Dump Truck Capacity: A Comprehensive Guide

What is 4 Axle Dump Truck Capacity?

At its core, 4-axle dump truck capacity refers to the maximum amount of material a truck can legally and safely transport. This isn’t a single, simple number, but rather a combination of two primary metrics:

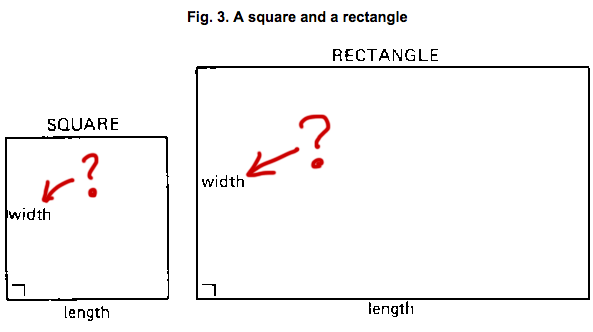

- Payload Capacity (Weight): This is the maximum weight of the material the truck can carry, typically measured in tons (US short tons) or metric tons. It’s determined by the truck’s Gross Vehicle Weight Rating (GVWR) minus its empty (tare) weight. The GVWR is the maximum permissible operating weight of the truck, including the vehicle itself, its fuel, driver, and the payload.

- Volumetric Capacity (Volume): This refers to the physical space available in the truck’s dump body, measured in cubic yards (cu yds) or cubic meters (m³). It dictates how much material can fit into the bed, regardless of its weight.

For a 4-axle dump truck, the presence of four axles (typically two steer axles at the front and two drive axles at the rear, or one steer, two drive, and one lift/tag axle) allows for a higher GVWR and, consequently, a greater payload capacity compared to 2 or 3-axle configurations. This design distributes the load more effectively over the road, complying with bridge laws and axle weight limits.

The importance of understanding these capacities cannot be overstated. Overloading can lead to severe consequences, including fines, accelerated vehicle wear and tear, increased fuel consumption, reduced safety, and even structural damage to roads and bridges. Underloading, conversely, means inefficient operations, higher per-ton transport costs, and lost revenue.

Key Factors Influencing 4-Axle Dump Truck Capacity

Several critical factors interact to define the practical capacity of a 4-axle dump truck:

- Gross Vehicle Weight Rating (GVWR): This is the fundamental limit set by the manufacturer, indicating the maximum operational weight of the truck. For 4-axle trucks, GVWRs typically range from 60,000 lbs (30 tons) to 80,000 lbs (40 tons), depending on the chassis, suspension, and axle ratings.

- Tare Weight (Empty Weight): This is the weight of the truck itself, without any payload. Lighter trucks (e.g., aluminum bodies, lightweight components) allow for a higher net payload capacity within the same GVWR. Tare weights for 4-axle dumps can vary significantly, often between 25,000 lbs to 35,000 lbs.

- Axle Weight Limits & Bridge Formulas: These are legal regulations imposed by federal, state, and local authorities to protect roadways and bridges. The Federal Bridge Formula is a complex calculation that limits the maximum weight that can be carried on a group of axles, based on the distance between them. States often have their own variations or stricter limits. A 4-axle truck’s design, particularly the spacing between its axles and the presence of lift/tag axles, is optimized to comply with these regulations while maximizing payload.

- Material Density: This is perhaps the most crucial variable for practical capacity. A truck might have a volumetric capacity of 20 cubic yards, but if it’s hauling dense material like wet sand (approx. 2,700-3,200 lbs/cu yd), it will hit its payload limit much faster than if it’s hauling lighter material like mulch (approx. 500-1,000 lbs/cu yd) or dry topsoil (approx. 2,000-2,400 lbs/cu yd).

- Example: A truck with a 40,000 lb (20 ton) payload capacity and a 20 cu yd body:

- Hauling dry topsoil (2,200 lbs/cu yd): Can only load ~18.18 cu yds (40,000 lbs / 2,200 lbs/cu yd) before hitting weight limit.

- Hauling mulch (800 lbs/cu yd): Can fill the entire 20 cu yds (16,000 lbs total), limited by volume, not weight.

- Example: A truck with a 40,000 lb (20 ton) payload capacity and a 20 cu yd body:

- Tire Ratings: Each tire has a maximum load rating. The sum of all tire ratings must exceed the maximum load the truck will carry on its axles.

- Suspension System: The type of suspension (e.g., spring, air ride) affects load distribution, stability, and ride quality, indirectly impacting the practical limits of the load.

- Road and Terrain Conditions: Operating on rough, unpaved roads or steep grades can necessitate reducing the effective payload to maintain safety and prevent damage.

Benefits of Optimal 4-Axle Capacity Utilization

Maximizing the capacity of your 4-axle dump truck offers significant advantages:

- Increased Efficiency: Fewer trips are needed to transport the same volume of material, reducing fuel consumption, labor hours, and wear on the truck.

- Cost Savings: Lower operational costs per ton of material moved directly translates to higher profitability.

- Reduced Environmental Impact: Fewer trips mean lower emissions.

- Versatility: A 4-axle truck can handle a wider range of materials, from light aggregates to heavy demolition debris, by adjusting the loaded volume to meet weight limits.

- Compliance & Safety: Properly loaded trucks are safer to operate, reduce the risk of accidents, and avoid costly fines and legal issues associated with overloading.

Practical Advice: How to Maximize & Manage Capacity

- Know Your Truck’s Specs: Obtain the exact GVWR, tare weight, and volumetric capacity from your truck’s documentation.

- Understand Material Densities: Always know the density of the material you are hauling. Keep a chart handy or use an app for quick reference.

- Utilize Onboard Scales: Many modern dump trucks are equipped with onboard weighing systems. These are invaluable tools for real-time load monitoring, ensuring you load to the legal limit without exceeding it.

- Calibrate Loading Procedures: Train operators to load accurately. For materials limited by weight, use a scale. For materials limited by volume, ensure the body is filled efficiently without mounding excessively.

- Consider Lift Axles (if applicable): If your 4-axle truck has a liftable fourth axle (often called a tag or pusher axle), understand when and how to deploy it to comply with bridge laws and distribute weight, especially for heavier loads.

- Regular Maintenance: Keep tires properly inflated and ensure suspension components are in good working order. These directly impact load-carrying capability and safety.

- Consult Local Regulations: State and local bridge laws and weight limits can vary significantly. Always check the specific regulations for the routes you will be traveling.

- Driver Training: Educate drivers on proper loading techniques, weight distribution, and the consequences of overloading.

Potential Challenges and Solutions

- Challenge: Overloading Fines & Penalties.

- Solution: Implement strict loading protocols, use onboard scales, and conduct regular weight checks. Educate drivers on legal limits and the risks of non-compliance.

- Challenge: Accelerated Wear & Tear.

- Solution: Operating within capacity limits significantly extends the lifespan of tires, brakes, suspension, and drivetrain components. Regular preventative maintenance is key.

- Challenge: Inefficient Loading/Underloading.

- Solution: Use material density calculations to optimize loads. If consistently under-utilizing capacity due to low-density materials, consider larger volume bodies or smaller trucks for those specific jobs. If frequently hitting weight limits before filling the body, explore lighter body materials (e.g., aluminum) or higher GVWR trucks for future purchases.

- Challenge: Varying State Regulations.

- Solution: For interstate operations, invest in routing software that accounts for state-specific weight limits. Maintain comprehensive records of vehicle specifications to present to enforcement officials.

Estimated Price Ranges and Typical Capacities for New 4-Axle Dump Trucks

The price of a new 4-axle dump truck can vary widely based on manufacturer (e.g., Peterbilt, Kenworth, Freightliner, Mack, Volvo), engine size, transmission type, body material (steel vs. aluminum), specialized features, and regional market conditions. The table below provides very general estimated ranges for new trucks and their typical capacities. These figures are subject to change and depend heavily on customization.

| Truck Type/Configuration | Typical Payload Capacity (Tons) | Typical Volumetric Capacity (Cu Yds) | Estimated New Price Range (USD) | Key Features/Considerations |

|---|