Ft Lorry Floor Size: The Unsung Hero of Efficient Logistics

Ft Lorry Floor Size: The Unsung Hero of Efficient Logistics cars.truckstrend.com

In the vast, intricate world of logistics and transportation, countless factors contribute to the smooth, timely, and cost-effective movement of goods. Among these, one dimension stands out as fundamentally critical, yet often goes unappreciated: Ft Lorry Floor Size. Far more than just a measurement, the floor size of a lorry dictates its operational capacity, influences strategic planning, impacts cost efficiencies, and ultimately, determines the success of a supply chain. This comprehensive guide will delve into what Ft Lorry Floor Size truly means, why it holds such immense importance, how to leverage it effectively, and answer common questions surrounding this vital aspect of freight transport.

What is Ft Lorry Floor Size?

Ft Lorry Floor Size: The Unsung Hero of Efficient Logistics

At its core, Ft Lorry Floor Size refers to the usable length and width of a lorry’s cargo bed or trailer, typically measured in feet. It defines the flat area available for loading goods. While the overall dimensions of a lorry include its cabin, engine, and structural components, the "floor size" specifically pertains to the space where the cargo resides. This measurement is crucial because it directly translates into the volume and type of goods a lorry can transport, influencing everything from the number of pallets it can accommodate to the length of specific items like steel beams or timber. Understanding this dimension is the first step in optimizing freight operations.

Why is Ft Lorry Floor Size Critical?

The seemingly simple measurement of a lorry’s floor size has profound implications across the logistics spectrum:

1. Payload Capacity and Volume Optimization

The most direct impact of floor size is on the lorry’s payload capacity. A larger floor allows for more goods, whether measured by volume (cubic feet) or by the number of standard units (e.g., pallets). Knowing the exact floor dimensions enables businesses to calculate how many items can fit, preventing under-utilization (wasted space) or overloading (safety and legal issues). This directly translates to fewer trips, saving fuel, labor, and wear-and-tear.

2. Logistics Efficiency and Route Planning

Optimal floor size selection is key to logistics efficiency. Using a lorry that is too large for a small load is uneconomical, while one that is too small requires multiple trips or transshipment, both adding costs and delays. Accurate floor size knowledge allows logistics managers to select the right vehicle for each job, optimize routes, and consolidate shipments, leading to faster transit times and reduced operational complexity.

3. Cost Management

Every foot of usable floor space has a financial implication. From fuel consumption and driver wages to maintenance and tolls, a lorry’s operational costs are often tied to its size and capacity utilization. By matching the floor size to the cargo, companies can significantly reduce their per-unit transportation costs, enhancing profitability.

4. Cargo Safety and Security

Properly utilizing the lorry floor size ensures cargo safety and security. When goods fit snugly within the designated area, they are less likely to shift during transit, reducing the risk of damage. Conversely, insufficient space can lead to improper stacking or securing, increasing the likelihood of accidents or product damage. Understanding the floor size helps in planning effective load distribution and securing methods.

5. Legal Compliance and Regulations

Governments impose strict regulations on vehicle dimensions and weight limits. Operating a lorry that exceeds permissible dimensions, even if the floor size is utilized, can lead to hefty fines, delays, and legal complications. Awareness of standard floor sizes and their associated legal limits is paramount for compliant operations.

6. Customer Satisfaction

Ultimately, the efficient use of lorry floor size contributes to customer satisfaction. Timely deliveries, goods arriving in pristine condition, and competitive pricing are all outcomes of optimized logistics, which heavily relies on selecting the appropriate vehicle size for the task.

Common Ft Lorry Floor Sizes and Their Applications

Lorry floor sizes vary significantly depending on the vehicle type and its intended purpose. Here are some common categories and their typical floor dimensions:

-

Small Vans/Light Commercial Vehicles (LCVs):

- Floor Size: 8-14 feet long x 5-6 feet wide (approx. 40-84 sq ft)

- Applications: Local courier services, small parcel delivery, urban distribution, express deliveries, tradespeople. Often used for loads up to 1-2 standard pallets.

-

Medium Rigid Lorries (7.5-ton to 18-ton GVW):

- Floor Size: 16-28 feet long x 8 feet wide (approx. 128-224 sq ft)

- Applications: Medium-distance distribution, construction materials, furniture delivery, supermarket supply. Can typically carry 8-14 standard pallets.

-

Large Rigid Lorries (26-ton GVW and above):

- Floor Size: 28-32 feet long x 8 feet wide (approx. 224-256 sq ft)

- Applications: Bulk goods, larger construction equipment, specialized deliveries. Can often accommodate 16-18 standard pallets.

-

Articulated Lorries (Tractor Units with Semi-Trailers):

- Standard Trailers (e.g., Curtain-siders, Box Trailers):

- Floor Size: 40-53 feet long x 8 feet wide (approx. 320-424 sq ft)

- Applications: Long-haul transportation, container shipping, large volume goods, general freight across regions/countries. Can hold 24-30 standard pallets.

- Specialized Trailers (e.g., Low-loaders, Flatbeds, Extendable Trailers):

- Floor Size: Highly variable, from 20 feet up to 100+ feet (when extended) x 8-10 feet wide.

- Applications: Oversized cargo, heavy machinery, abnormal loads.

- Standard Trailers (e.g., Curtain-siders, Box Trailers):

How to Determine the Optimal Ft Lorry Floor Size for Your Needs

Selecting the correct lorry floor size is a strategic decision. Here’s a step-by-step guide:

-

Assess Cargo Type and Volume:

- Dimensions: Measure the length, width, and height of your individual items or pallets.

- Quantity: Determine the total number of items or pallets.

- Stackability: Can items be stacked? If so, how high? This affects total usable volume within a given floor area.

- Irregular Shapes: Account for any non-standard shapes that might require more floor space than their base footprint suggests.

-

Consider Cargo Weight (Density):

- While floor size dictates volume, the weight of your cargo is equally important. Dense items might fill the weight capacity of a lorry before its floor space is fully utilized. Always cross-reference your volume needs with the lorry’s Gross Vehicle Weight (GVW) or Gross Combination Weight (GCW).

-

Evaluate Route and Access Restrictions:

- Urban vs. Rural: Smaller lorries are more agile in congested urban areas with narrow streets.

- Delivery Points: Are there loading dock limitations? Tight turning circles? Low bridge clearances? These can restrict the size of the lorry that can access your delivery or collection points.

-

Frequency of Shipments:

- If you have frequent, smaller shipments, a fleet of medium-sized lorries might be more efficient than one large articulated lorry. Conversely, consistent large volumes warrant larger vehicles.

-

Budget Considerations:

- Larger lorries generally have higher purchase, rental, fuel, and maintenance costs. Balance the need for capacity with financial viability.

-

Future Needs and Scalability:

- Anticipate future growth or changes in your cargo profile. Investing in a versatile fleet or having access to a range of vehicle sizes through logistics partners can provide flexibility.

Tips for Maximizing Lorry Floor Space

Even with the right lorry size, efficient loading is crucial:

- Palletization and Unitization: Standardize your cargo into uniform units (e.g., standard Euro pallets or industrial pallets) to simplify loading calculations and maximize floor coverage.

- Load Planning Software: Utilize advanced software to create optimal load plans, considering dimensions, weight distribution, and stacking capabilities.

- Proper Stacking and Securing: Stack goods carefully, using dunnage, load bars, straps, and nets to prevent movement and damage during transit. Consider vertical space utilization.

- Backhauling and Return Loads: Wherever possible, plan for return loads to minimize "empty miles," effectively making the most of the lorry’s floor space on both legs of a journey.

- Regular Maintenance: Ensure the lorry floor is always in good condition, free from damage that could impede loading or compromise cargo safety.

Challenges and Solutions Related to Lorry Floor Size

Challenges:

- Under-utilization: Sending a large lorry with a small load, leading to wasted capacity and higher per-unit costs.

- Overloading: Exceeding the vehicle’s weight limit, even if the floor space isn’t full, leading to fines and safety risks.

- Access Issues: Large lorries unable to access certain delivery points due to size constraints.

- Specific Cargo Needs: Fragile, temperature-sensitive, or hazardous materials may require specialized handling or dedicated space, limiting floor utilization for other goods.

Solutions:

- Mixed Fleet Strategy: Maintain or access a range of lorry sizes to match varying cargo demands.

- Precise Load Planning: Invest in skilled personnel or software to accurately plan loads, consolidating shipments where possible.

- Transshipment Hubs: Utilize strategically located hubs where larger loads can be broken down and transferred to smaller vehicles for final mile delivery.

- Driver Training: Ensure drivers are trained in safe and efficient loading, weight distribution, and securing techniques.

- Technology Integration: Use GPS tracking, telematics, and real-time data to optimize routes and identify opportunities for backhauls.

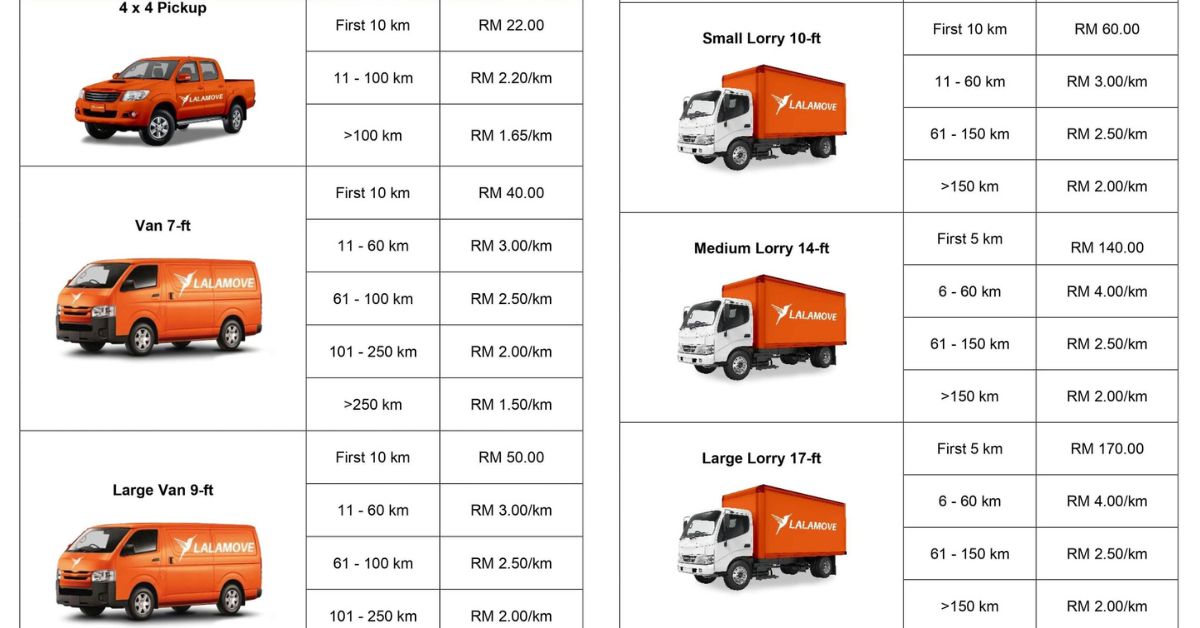

Price Table: Estimated Costs Associated with Ft Lorry Floor Sizes

It’s important to note that "price" for "Ft Lorry Floor Size" is not a direct commodity. Instead, the floor size is a primary determinant of a lorry’s overall capacity, which in turn influences its purchase price, rental cost, and operational expenses. The table below provides approximate cost ranges for typical lorry types, heavily influenced by their standard floor sizes. These figures are illustrative and can vary widely based on location, vehicle age, brand, features, fuel prices, and specific service agreements (for rental/hire).

| Lorry Type (Primary Descriptor by Floor Size) | Typical Floor Size (Length x Width) | Est. Purchase Price (New) | Est. Daily Rental/Hire Cost | Key Operational Considerations |

|---|

Ft Lorry Floor Size: The Essential Guide to Maximizing Your Logistics Efficiency

In the complex ecosystem of modern supply chains, every detail matters. From route optimization to cargo handling, precision can translate directly into profitability. Among these crucial details, the Ft Lorry Floor Size stands as a foundational element, often underestimated but profoundly impactful. This dimension, representing the usable internal area of a lorry’s cargo bed or trailer in feet, is far more than just a measurement; it’s a strategic asset that dictates capacity, influences operational costs, ensures compliance, and ultimately underpins the efficiency of freight transportation.

This comprehensive guide will demystify Ft Lorry Floor Size, exploring its critical importance, common types, practical applications, and actionable insights to help businesses optimize their logistics operations. Whether you’re a seasoned logistics professional or new to the world of freight, understanding this fundamental concept is key to making informed decisions and unlocking significant efficiencies.

What Exactly is Ft Lorry Floor Size?

Ft Lorry Floor Size refers to the length and width of the flat, load-bearing surface within the cargo compartment of a lorry or its trailer, expressed in feet. While a lorry has an overall length (bumper to bumper), the floor size specifically isolates the dedicated space where goods are loaded, stacked, and secured. For instance, a "40-foot trailer" typically implies a floor length of approximately 40 feet, though the exact usable space might be slightly less due to internal bulkheads or specific trailer designs. This measurement is distinct from the lorry’s Gross Vehicle Weight (GVW) or Gross Combination Weight (GCW), which refer to its maximum permissible loaded weight. While weight capacity is vital, floor size determines how much volume or how many units (like pallets) can physically fit.

Why Ft Lorry Floor Size is a Critical Factor in Logistics

The implications of accurately understanding and utilizing Ft Lorry Floor Size ripple throughout the entire logistics chain:

1. Maximizing Payload and Volume Utilization

The most direct benefit is the ability to maximize payload and volume. By knowing the precise floor dimensions, businesses can calculate the exact number of pallets, crates, or individual items that can be loaded. This prevents the costly scenario of under-utilizing space (shipping air) or, conversely, over-estimating capacity, leading to incomplete shipments or the need for additional, unplanned trips. Optimal utilization means fewer journeys are required to move the same amount of goods.

2. Enhancing Operational Efficiency and Cost Reduction

Choosing the right lorry floor size for a specific shipment is a cornerstone of operational efficiency. A lorry that’s too large for a small load is inefficient and costly in terms of fuel consumption and driver wages. Conversely, a lorry that’s too small might necessitate multiple trips or complex transshipments, adding time, labor, and potential for damage. Matching the vehicle to the cargo size reduces "empty miles," optimizes fuel expenditure, and lowers overall transportation costs.

3. Ensuring Cargo Safety and Integrity

Proper utilization of the lorry floor size is paramount for cargo safety. When goods fit securely and are distributed correctly across the floor area, they are less prone to shifting, sliding, or toppling during transit. This reduces the risk of product damage, which can lead to significant financial losses and customer dissatisfaction. Adequate floor space allows for proper securing methods like strapping, chocking, and bracing, further safeguarding the cargo.

4. Facilitating Regulatory Compliance

Logistics operations are governed by a myriad of regulations concerning vehicle dimensions, weight limits, and load securing. Understanding the standard Ft Lorry Floor Sizes associated with different vehicle classifications helps ensure compliance with local, national, and international laws. Avoiding oversized loads or weight violations prevents hefty fines, operational delays, and potential legal ramifications.

5. Strategic Route Planning and Access Management

The physical dimensions of a lorry, heavily influenced by its floor size, directly impact route planning. Larger lorries with longer floor sizes may be restricted on certain roads, bridges, or in urban areas with tight turning radii. Knowing the vehicle’s footprint allows planners to select appropriate routes, avoid inaccessible areas, and ensure seamless last-mile delivery, especially to sites with limited loading dock space or narrow access points.

Common Ft Lorry Floor Sizes and Their Primary Applications

Lorry floor sizes vary considerably based on their design, purpose, and the gross vehicle weight (GVW) they are rated for. Here’s a breakdown of common categories and their typical floor dimensions:

-

Small Rigid Lorries (e.g., 3.5-ton to 7.5-ton GVW):

- Typical Floor Size: 10 to 18 feet long x 7 to 8 feet wide (approx. 70-144 sq ft)

- Common Applications: Local urban deliveries, express freight, parcel services, furniture transport, smaller construction supplies. Often used for loads of 4-8 standard pallets. Agile in congested areas.

-

Medium Rigid Lorries (e.g., 18-ton to 26-ton GVW):

- Typical Floor Size: 20 to 30 feet long x 8 to 8.5 feet wide (approx. 160-255 sq ft)

- Common Applications: Regional distribution, general freight, building materials, refrigerated goods. Can typically accommodate 10-16 standard pallets. Offers a good balance of capacity and maneuverability.

-

Standard Articulated Lorries (Tractor & Semi-Trailer):

- Typical Floor Size (Standard Trailer): 40 to 53 feet long x 8.2 feet wide (approx. 328-435 sq ft)

- Common Applications: Long-haul transportation, bulk goods, container shipping, large volume retail distribution. The most common type for inter-city and international freight, capable of carrying 24-30 standard pallets.

-

Specialized Trailers (e.g., Flatbeds, Low-loaders, Extendable Trailers):

- Typical Floor Size: Highly variable, from 20 feet (short flatbed) to over 100 feet (extended low-loader) in length, and often 8-10 feet wide.

- Common Applications: Transporting oversized or unusually shaped cargo (e.g., heavy machinery, wind turbine blades, modular homes). Floor size is often customized or extendable for specific project needs.

How to Determine the Optimal Ft Lorry Floor Size for Your Needs

Choosing the right lorry floor size is a strategic decision that directly impacts efficiency and cost. Follow these steps to make an informed choice:

-

Analyze Your Cargo’s Physical Characteristics:

- Dimensions: Measure the exact length, width, and height of your individual packages, crates, or pallets. This is paramount.

- Volume: Calculate the total cubic footage required.

- Stackability: Determine if your goods can be safely stacked, and to what height. This allows for vertical space utilization.

- Irregular Shapes: Account for any awkward shapes that may consume more floor space than their base footprint suggests or prevent adjacent loading.

-

Consider the Cargo’s Weight and Density:

- While floor size defines volume, the cargo’s weight dictates how much a lorry can legally carry. Highly dense items (e.g., steel, liquids) may fill a lorry’s weight capacity long before its floor space is fully utilized. Always cross-reference volume needs with the lorry’s payload weight limit.

-

Evaluate Delivery and Collection Point Accessibility:

- Loading Docks: Do your sites have standard loading docks, or require ramp access?

- Maneuverability: Are the roads leading to and from your locations narrow, winding, or congested? Are there tight corners, low bridges, or overhead power lines? These factors might necessitate smaller, more agile vehicles, even if a larger one could theoretically hold the cargo.

-

Assess Shipment Frequency and Volume Consistency:

- For consistent, high-volume shipments, investing in or regularly hiring larger lorries is usually more cost-effective.

- For sporadic or smaller, frequent shipments, a mixed fleet or utilizing less-than-truckload (LTL) services with smaller vehicles might be more economical.

-

Factor in Budget and Cost-Benefit Analysis:

- Larger lorries typically have higher capital costs (purchase/lease), higher fuel consumption, and higher maintenance expenses. Weigh these against the cost savings from reduced trips and increased efficiency.

Practical Advice and Actionable Insights

- Invest in Accurate Measurement Tools: Ensure your team has reliable tools (tape measures, laser distance meters) and standard operating procedures for measuring cargo.

- Standardize Packaging: Where possible, use standard pallet sizes (e.g., Euro pallets: 1200x800mm; North American pallets: 48×40 inches) to simplify load planning and maximize floor utilization.

- Leverage Load Planning Software: Modern logistics software can simulate load configurations, optimize space, and ensure proper weight distribution, reducing manual errors and maximizing efficiency.

- Prioritize Driver Training: Well-trained drivers can optimize loading, secure cargo effectively, and navigate challenging access points, minimizing delays and damages.

- Consider Backhauling: Actively seek return loads or arrange for suppliers to utilize your empty return trips. This maximizes the utilization of the lorry’s floor space for both legs of a journey, significantly reducing costs.

- Regular Floor Inspection: Ensure the lorry’s floor is well-maintained, clean, and free of damage to prevent cargo shifts and ensure a stable loading surface.

Table: Illustrative Costs Associated with Different Lorry Floor Sizes

It’s crucial to understand that "price" for "Ft Lorry Floor Size" is not a direct commodity. Rather, the floor size is a primary characteristic influencing the overall cost of a lorry, whether purchased, leased, or hired. The table below provides estimated cost ranges for typical lorry types, heavily influenced by their standard floor sizes. These figures are illustrative and can vary significantly based on region, vehicle specifications, age, brand, fuel prices, driver wages, and specific service agreements (for rental/hire).

| Lorry Type (Common Floor Size Range) | Typical GVW (Gross Vehicle Weight) | Est. Purchase Price (New, USD) | Est. Daily Rental/Hire Cost (USD) | Est. Cost Per Mile (Operational, USD) | Primary Benefit of Floor Size |

|---|