Most Difficult Car Brands To Repair: Navigating the Complexities of Automotive Maintenance

Most Difficult Car Brands To Repair: Navigating the Complexities of Automotive Maintenance cars.truckstrend.com

Introduction: The Hidden Costs of Automotive Excellence

Owning a car is a significant investment, and while initial purchase price and fuel efficiency often dominate our decision-making, the long-term cost of maintenance and repairs can often be a surprising and substantial burden. Some car brands, renowned for their performance, luxury, and advanced technology, come with an unspoken caveat: they are notoriously difficult and expensive to repair. This "difficulty" stems from a combination of factors including intricate engineering, proprietary diagnostic tools, specialized parts, and the high level of expertise required from technicians.

Most Difficult Car Brands To Repair: Navigating the Complexities of Automotive Maintenance

Understanding which car brands fall into this category and, more importantly, why they do, is crucial for any prospective or current owner. It impacts everything from your annual budget and the availability of qualified mechanics to the car’s long-term reliability and resale value. This comprehensive guide will delve into the world of challenging automotive repairs, identifying the culprits, explaining the underlying reasons for their complexity, and offering practical advice to navigate these often-costly waters.

The German Engineering Enigma: Precision, Performance, and Puzzles

German luxury brands like BMW, Mercedes-Benz, Audi, and Porsche are synonymous with engineering excellence, cutting-edge technology, and exhilarating performance. However, this very sophistication is often their Achilles’ heel when it comes to repairs.

- Intricate Electronics and Sensors: Modern German vehicles are essentially computers on wheels. They feature an astounding number of interconnected electronic control units (ECUs), sensors, and complex wiring harnesses that manage everything from engine performance and transmission shifts to infotainment and advanced driver-assistance systems (ADAS). A single fault in one sensor can trigger a cascade of error codes, making diagnosis a time-consuming and often expensive process.

- Proprietary Diagnostic Tools: Unlike more common vehicles, diagnosing issues in a BMW or Mercedes-Benz often requires manufacturer-specific diagnostic software and hardware (e.g., BMW’s ISTA, Mercedes-Benz’s XENTRY/DAS). These tools are expensive, require regular updates, and are typically only available to authorized dealerships or highly specialized independent shops. Generic OBD-II scanners can read basic codes but often lack the depth needed for precise troubleshooting.

- Integrated Systems: Components are not standalone; they are deeply integrated. For example, a failing air suspension module might be intertwined with the car’s stability control or even its navigation system. This integration means that replacing one part might necessitate recalibration or programming of several other systems, adding layers of complexity and labor time.

- Tight Packaging: To achieve optimal weight distribution and performance, German engineers often pack components tightly into the engine bay and chassis. This can make simple tasks, like accessing spark plugs or changing a serpentine belt, incredibly difficult, requiring the removal of multiple surrounding components.

- High Cost of Genuine Parts: While aftermarket parts exist, many critical components for German luxury cars are best replaced with original equipment manufacturer (OEM) parts, which are significantly more expensive than their counterparts for mainstream brands. The quality and precise fit of OEM parts are often crucial for the vehicle’s optimal performance and longevity.

- Specialized Technician Training: Mechanics working on these brands require extensive, ongoing training to keep up with the rapid pace of technological advancements. This specialized knowledge comes at a premium, reflected in higher labor rates.

The British Luxury Labyrinth: Elegance, Off-Road Prowess, and Electronic Gremlins

Brands like Land Rover and Jaguar offer unparalleled luxury, distinctive styling, and, in Land Rover’s case, legendary off-road capability. Yet, they too present unique challenges in the repair bay.

- Electronic Complexity and Reliability: Historically, British luxury vehicles, especially older models, have faced a reputation for electronic glitches. While modern iterations have improved, their sheer number of complex electronic modules, particularly in systems like air suspension, infotainment, and terrain response, can still lead to perplexing diagnostic challenges.

- Air Suspension Systems: Many Land Rover models, and some Jaguars, feature sophisticated air suspension systems. While offering a sublime ride and adjustable height, these systems are prone to leaks, compressor failures, and sensor malfunctions, all of which are expensive to diagnose and repair due to specialized components and the need for calibration.

- Unique Body Construction: Land Rover, in particular, utilizes advanced materials like aluminum extensively in their vehicle architectures. Repairing collision damage on these vehicles requires specialized equipment (e.g., aluminum welding gear) and highly trained technicians, making bodywork repairs significantly more expensive and less accessible than for steel-bodied cars.

- Parts Availability and Cost: Due to lower production volumes compared to mass-market brands, certain parts for Land Rover and Jaguar can be less readily available and consequently more expensive, sometimes requiring international ordering.

The Italian Exotics: Art, Anguish, and Astronomical Bills

Ferrari, Lamborghini, and Maserati represent the pinnacle of automotive artistry and performance. Owning one is a dream for many, but maintaining one is a reality reserved for the very few, primarily due to exorbitant repair costs and extreme complexity.

- Extremely Rare and Expensive Parts: Many components in these hand-built machines are produced in very limited quantities or are bespoke, making them incredibly rare and astonishingly expensive. A simple headlight assembly or a specific engine sensor could cost thousands.

- Limited Qualified Technicians: The pool of mechanics truly qualified to work on these vehicles is minuscule. These are often factory-trained experts who command very high labor rates and are only found at authorized dealerships or a handful of elite independent specialists.

- Hand-Built Nature and Variations: Because many parts are hand-assembled, there can be subtle variations between individual vehicles, making standardized repairs more challenging. Each car might have its own quirks.

- Difficult Access: Mid-engine and rear-engine layouts, combined with tightly packed, high-performance components, often mean that even routine maintenance, like accessing spark plugs or belts, can require significant disassembly of the vehicle, including removing rear body panels or even lifting the engine out. This translates directly to incredibly high labor hours.

- Specialized Tools and Equipment: Repairs often require unique, custom-fabricated tools that are specific to a particular model or even a specific year of production.

Advanced Japanese & Niche American: Sophistication with a Price Tag

While Japanese brands are generally known for reliability, Lexus and Acura (Honda’s luxury division) can present repair challenges, especially their higher-end models with hybrid powertrains or advanced electronics. Similarly, some high-performance or technologically advanced American vehicles like certain Cadillac models, Corvettes, or Teslas can also be difficult.

- Lexus/Acura: Their hybrid systems are incredibly complex and require specialized knowledge and equipment for diagnosis and repair. The precision engineering, while contributing to reliability, also means less tolerance for non-OEM parts or amateur repairs.

- Tesla: As a relatively new automotive paradigm, Tesla vehicles present unique challenges.

- EV Architecture: The high-voltage battery packs, electric motors, and unique cooling systems require specialized training and safety protocols for repair.

- Software-Defined Components: Many functions are controlled by software, and diagnostics often involve proprietary software updates or reconfigurations, limiting independent repair options.

- Limited Third-Party Access: Tesla has historically restricted access to diagnostic tools and parts for independent shops, pushing owners towards their service centers, which can have long wait times and high costs.

- Body Structure: Their large battery packs are integral to the vehicle’s structure, making collision repairs involving the battery extremely complex and expensive.

- Performance American (e.g., Cadillac V-series, Corvette): These vehicles feature high-output engines, sophisticated transmissions, and advanced suspension systems (like magnetic ride control) that are distinct from their standard counterparts. They often require specialized diagnostic procedures and specific tools, increasing repair complexity and cost compared to base models.

Common Factors Contributing to Repair Difficulty

Beyond brand-specific issues, several overarching factors make certain cars difficult to repair:

- Proprietary Tools & Software: The increasing reliance on manufacturer-specific diagnostic equipment locks out many general mechanics.

- Integrated Systems: When multiple vehicle functions are interdependent, a fault in one system can impact others, making diagnosis a "needle in a haystack" problem.

- Specialized Materials & Construction: Use of lightweight alloys (aluminum, magnesium) and carbon fiber requires specific repair techniques and equipment not found in every shop.

- Limited Aftermarket Parts: Less popular or highly specialized vehicles have fewer aftermarket parts options, forcing reliance on more expensive OEM components.

- Technician Training: The constant evolution of automotive technology demands continuous, costly training for mechanics, which is factored into labor rates.

- Tight Packaging: Cramped engine bays or chassis designs make accessing components physically challenging, increasing labor time.

Practical Advice and Actionable Insights

If you own or are considering one of these challenging-to-repair brands, here’s how to mitigate the potential pain:

- Research Thoroughly Before Buying: Understand the common issues and average repair costs for the specific model and year you’re interested in. Online forums and owner communities can be invaluable resources.

- Factor in Repair Costs: Don’t just budget for the purchase price. Set aside a substantial contingency fund for unexpected repairs, or factor higher annual maintenance costs into your budget.

- Choose a Reputable, Specialized Mechanic: Avoid general repair shops for these vehicles. Seek out independent mechanics who specialize in your car’s brand. They will have the correct tools, software, and expertise, often at a lower labor rate than a dealership. Ask for recommendations and check online reviews.

- Consider an Extended Warranty or Service Plan: For newer vehicles, a comprehensive extended warranty can be a lifesaver, covering expensive repairs that would otherwise drain your bank account.

- Adhere Strictly to Maintenance Schedules: Proactive maintenance is paramount. Skipping fluid changes or inspections can lead to far more expensive problems down the line.

- Don’t Ignore Warning Lights: Address warning lights immediately. A minor issue left unattended can quickly escalate into a major, costly repair.

- Keep Detailed Service Records: A well-documented service history not only helps your mechanic but also significantly boosts the car’s resale value.

- Be Wary of Cheap Deals: A significantly undervalued luxury car might be hiding a multitude of expensive problems. Get a thorough pre-purchase inspection from a specialist.

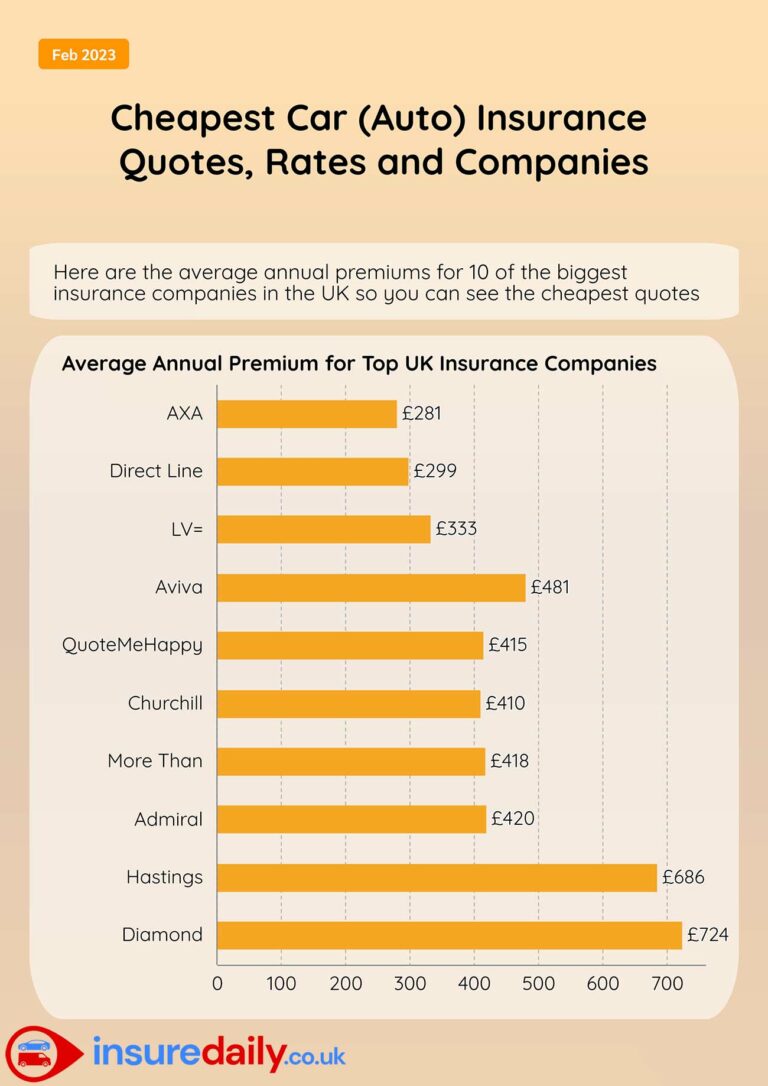

Estimated Comparative Repair Cost Factors Table

Please note: These figures are highly generalized estimates and actual costs will vary widely based on location, specific repair, technician rates, and parts availability. This table serves as a relative guide to complexity and cost.

| Car Brand Category | Complexity Factor (1-5, 5=Highest) | Estimated Hourly Labor Rate (Relative) | Estimated Parts Cost Factor (Relative) | Common Repair Examples (Relative Cost) |

|---|---|---|---|---|

| Mainstream (Toyota, Honda, Ford) | 1-2 | Standard | Standard | Brake job: Low, Alternator: Low-Medium, Transmission: Medium-High |

| Luxury German (BMW, Mercedes, Audi) | 3-4 | 1.5x – 2x Standard | 2x – 3x Standard | Electronics diagnosis: High, Air suspension: High, Engine sensors: Medium-High |

| Luxury British (Land Rover, Jaguar) | 3-4 | 1.5x – 2x Standard | 2x – 3.5x Standard | Air suspension: High, Electrical gremlins: High, Body repairs (aluminum): Very High |

| Advanced Japanese (Lexus Hybrid, Acura) | 2.5-3.5 | 1.2x – 1.8x Standard | 1.5x – 2.5x Standard | Hybrid battery: Very High, Complex electronics: High, Transmission: High |

| Niche American (Tesla, Performance GM/Ford) | 3.5-4.5 | 1.8x – 2.5x Standard | 2.5x – 4x Standard | Tesla battery/motor: Very High, Software issues: High, Performance engine rebuild: Very High |

| Italian Exotics (Ferrari, Lamborghini, Maserati) | 5 | 3x – 5x+ Standard | 5x – 10x+ Standard | Any major component: Astronomical, Routine service: Very High, Engine out service: Extremely High |

Relative Hourly Labor Rate: Multiplier compared to a standard independent mechanic’s hourly rate for a mainstream car (e.g., $100/hour).

Relative Parts Cost Factor: Multiplier compared to the cost of equivalent parts for a mainstream car.

Frequently Asked Questions (FAQ)

Q1: Are older luxury cars harder to repair than new ones?

A1: Often, yes. While newer cars have more complex electronics, older luxury cars can suffer from parts obsolescence, lack of updated diagnostic software, and accumulated wear and tear on components that are no longer easily available. Finding mechanics with expertise in older, specific systems can also be challenging.

Q2: Can I use aftermarket parts for these difficult-to-repair brands?

A2: For some components (e.g., brakes, certain suspension parts), quality aftermarket parts may be available and can save money. However, for critical engine, transmission, or electronic components, OEM (Original Equipment Manufacturer) parts are almost always recommended due to precise fit, quality, and compatibility with complex integrated systems. Using non-OEM parts can sometimes lead to further issues or void warranties.

Q3: Is DIY repair ever an option for these cars?

A3: For basic maintenance (oil changes, tire rotations), yes, if you have the proper tools and knowledge. However, for anything beyond the simplest tasks, DIY repair on these complex vehicles is highly discouraged. The specialized tools, diagnostic software, and intricate systems require professional expertise, and a mistake can lead to much more expensive damage.

Q4: How do I find a good mechanic for a difficult-to-repair car?

A4: Start by asking for recommendations from other owners of the same brand in online forums or local car clubs. Check online reviews, and look for independent shops that specialize exclusively in your car’s brand. Verify they have the latest diagnostic equipment and certified technicians for your vehicle’s systems.

Q5: Does electric vehicle (EV) technology make repairs easier or harder?

A5: It’s a mixed bag. EVs eliminate many traditional ICE (internal combustion engine) components like spark plugs, oil changes, and complex transmissions, simplifying some maintenance. However, they introduce new complexities: high-voltage battery systems, specialized motor repairs, and heavily software-dependent diagnostics. Collision repair involving battery packs is particularly complex and expensive, and the lack of independent repair access for some brands (like Tesla) can make EV repairs challenging.

Conclusion: Informed Ownership is Key

The allure of a high-performance, luxurious, or technologically advanced vehicle is undeniable. However, beneath the gleaming paint and plush interiors lies a world of intricate engineering that can translate into significant repair challenges and costs. Brands like Ferrari, Lamborghini, Land Rover, BMW, Mercedes-Benz, and even advanced Teslas, while offering unparalleled driving experiences, demand a higher level of financial commitment and informed ownership when it comes to maintenance.

Understanding why these vehicles are difficult to repair – from proprietary diagnostics and integrated systems to specialized parts and the need for highly trained technicians – empowers owners to make better decisions. By choosing the right mechanic, adhering to maintenance schedules, and budgeting wisely, you can mitigate the financial impact and ensure your dream car remains a source of joy, not a constant drain on your wallet. Ultimately, the most difficult car brands to repair are not necessarily unreliable, but rather, require a level of care and financial foresight commensurate with their sophisticated design.