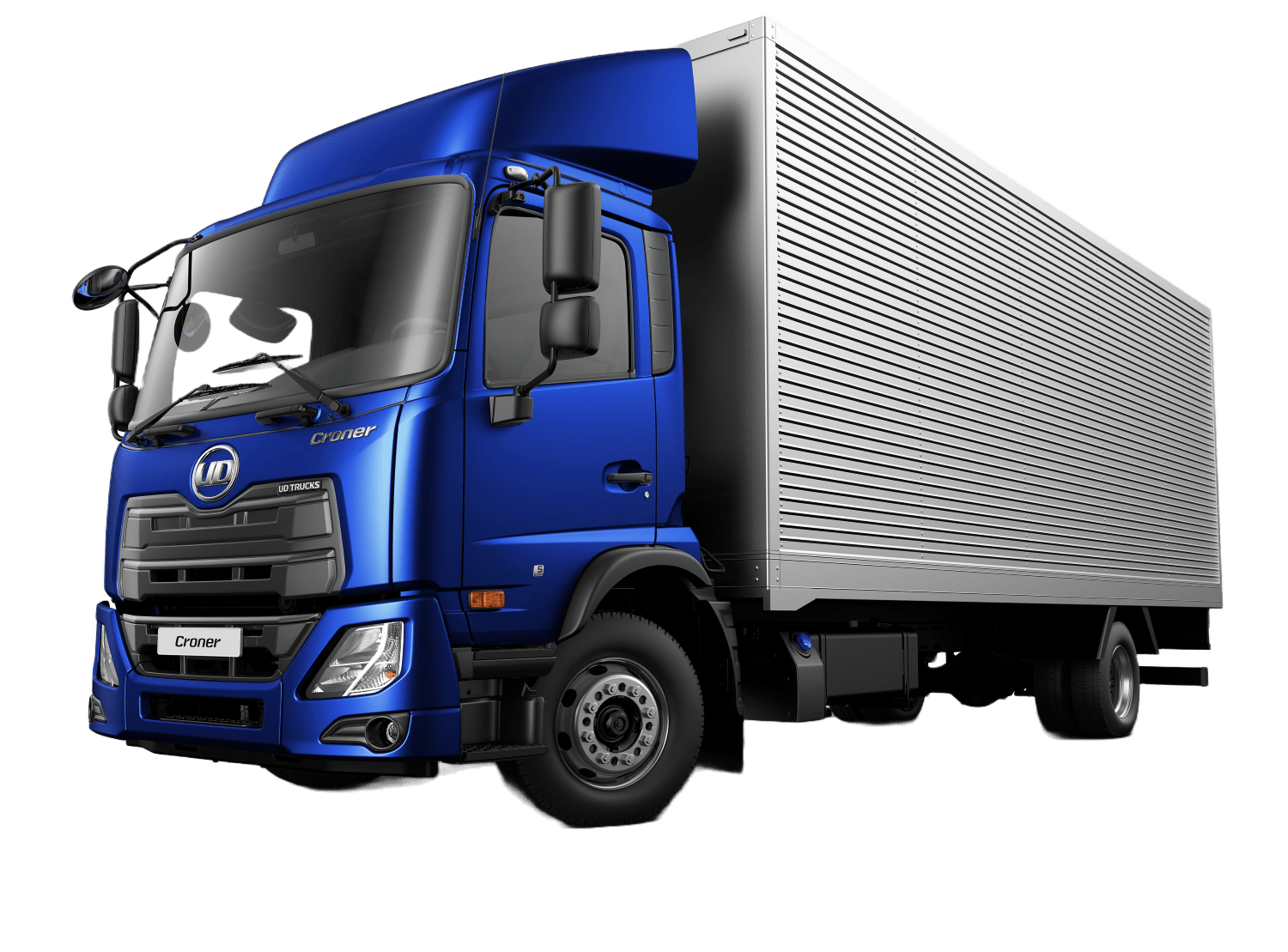

Truck Part Names: A Comprehensive Guide to Understanding Your Vehicle

Truck Part Names: A Comprehensive Guide to Understanding Your Vehicle cars.truckstrend.com

The hum of a powerful engine, the sheer size, the ability to haul immense loads – trucks are engineering marvels. Whether you’re a professional driver, a fleet manager, a mechanic, or simply an enthusiast, understanding the intricate network of components that make up these robust machines is not just fascinating, it’s essential. Knowing the names of truck parts is the foundational language for maintenance, repair, troubleshooting, and even safe operation. It allows for clear communication, informed decision-making, and ultimately, keeps these workhorses on the road.

This comprehensive guide will demystify the complex world of truck part names, breaking down the vehicle into its major systems and exploring the key components within each. From the mighty engine to the smallest sensor, we’ll equip you with the vocabulary to navigate the anatomy of a truck with confidence.

Truck Part Names: A Comprehensive Guide to Understanding Your Vehicle

The Anatomy of a Truck: Major Systems Overview

A modern truck is a sophisticated integration of various systems, each playing a vital role in its overall function. To better understand individual parts, it’s helpful to categorize them by the system they belong to. The primary systems include:

- Engine & Powertrain: The heart of the truck, responsible for generating power and transmitting it to the wheels.

- Chassis, Suspension & Steering: The structural backbone, providing support, absorbing road shocks, and controlling direction.

- Braking System: Critical for slowing down and stopping the vehicle safely.

- Electrical & Lighting System: Powers all electronic components, ensures visibility, and provides communication.

- Cab & Body: The driver’s workspace and the external shell of the truck.

- Auxiliary & Specialized Components: Parts unique to commercial trucking, such as fifth wheels, PTOs, and exhaust aftertreatment.

Let’s delve into the specific components within each system.

Essential Engine & Powertrain Components

The engine is where the magic of combustion happens, converting fuel into kinetic energy. The powertrain then transfers this energy to the drive wheels.

- Engine Block: The main structure of the engine, housing the cylinders.

- Cylinder Head: Sits atop the engine block, containing valves, camshafts, and spark plugs/fuel injectors.

- Pistons: Reciprocating components that move up and down within the cylinders, compressing the air-fuel mixture.

- Crankshaft: Converts the linear motion of the pistons into rotational motion.

- Camshaft: Controls the opening and closing of the engine’s intake and exhaust valves.

- Turbocharger/Supercharger: Forces more air into the engine, increasing power output.

- Fuel Injectors: Atomize and spray fuel into the combustion chambers.

- Oil Pan: Stores the engine oil for lubrication.

- Radiator: Dissipates heat from the engine coolant.

- Water Pump: Circulates coolant through the engine and radiator.

- Fan (Engine Fan): Draws air through the radiator for cooling.

- Alternator: Generates electrical power to recharge the battery and power electrical systems.

- Starter Motor: Engages the flywheel to crank the engine and initiate combustion.

Powertrain Components:

- Transmission (Gearbox): Changes the gear ratio between the engine and the drive wheels, allowing for varying speeds and torque. Can be manual or automatic.

- Clutch (Manual Transmissions): Disengages and engages power from the engine to the transmission.

- Driveshaft (Propeller Shaft): Transmits rotational power from the transmission to the differential.

- Differential: Allows the drive wheels to rotate at different speeds when turning.

- Axles (Drive Axles/Steer Axles): Shafts that connect the wheels to the differential and support the weight of the truck.

- U-Joints (Universal Joints): Flexible couplings in the driveshaft that allow for changes in angle.

Chassis, Suspension & Steering System Parts

These components provide the structural integrity, ride comfort, and directional control of the truck.

- Frame Rails (Chassis Frame): The primary structural members that run the length of the truck, supporting all other components.

- Crossmembers: Horizontal members connecting the frame rails, adding rigidity.

- Leaf Springs: Layers of curved steel plates that absorb road shocks (common in heavy trucks).

- Air Springs (Air Bags): Inflatable rubber bladders that provide a softer, adjustable ride.

- Shock Absorbers (Dampers): Control spring oscillation and dampen road bumps.

- Control Arms (A-Arms): Connect the suspension to the frame, guiding wheel movement.

- U-Bolts: U-shaped bolts that secure leaf springs to axles.

- Kingpins: Pivots in the steer axle that allow the wheels to turn.

- Steering Gearbox (Steering Box): Converts the rotational motion of the steering wheel into linear motion to move the wheels.

- Power Steering Pump: Provides hydraulic assistance for easier steering.

- Tie Rods: Connect the steering knuckles to the steering gear, transmitting steering input to the wheels.

- Drag Link: Connects the steering gearbox to the steering arm.

Braking System Components: Ensuring Safety

The braking system is paramount for safety, allowing the driver to control the vehicle’s speed and bring it to a complete stop. Heavy trucks primarily use air brakes.

- Brake Drums/Rotors: The rotating components that brake pads/shoes press against. Drums are common on older trucks and trailers, rotors (discs) on modern trucks.

- Brake Pads/Shoes: Friction material that presses against the drums/rotors to create braking force.

- Calipers (Disc Brakes): House the brake pads and hydraulic/air pistons that press them against the rotor.

- Brake Chambers (Air Brakes): Convert compressed air pressure into mechanical force to apply the brakes.

- Slack Adjusters: Adjust the distance between the brake shoes/pads and the drum/rotor as they wear.

- Brake Lines (Air/Hydraulic): Carry air pressure or hydraulic fluid to the brake chambers/calipers.

- Master Cylinder (Hydraulic Brakes): Converts pedal pressure into hydraulic pressure.

- Air Compressor (Air Brakes): Generates compressed air for the braking system and other air-operated accessories.

- Air Dryer: Removes moisture and contaminants from the compressed air system.

- ABS Module (Anti-lock Braking System): Electronically prevents wheel lock-up during hard braking.

Electrical & Lighting System Essentials

The electrical system powers everything from the engine’s ignition to the cab’s creature comforts, while lighting ensures visibility and compliance.

- Battery: Stores electrical energy for starting the engine and powering accessories when the engine is off.

- Alternator: Recharges the battery and powers electrical systems when the engine is running.

- Starter Motor: Uses battery power to crank the engine for ignition.

- Wiring Harness: Bundles of wires that transmit electrical signals and power throughout the truck.

- ECU/ECM (Engine Control Unit/Module): The "brain" of the engine, controlling fuel injection, ignition timing, and emissions.

- Fuses & Relays: Protect electrical circuits from overcurrent and control high-current components.

- Headlights: Provide illumination for forward visibility.

- Taillights/Brake Lights: Indicate the rear of the truck and when the brakes are applied.

- Marker Lights/Clearance Lights: Indicate the truck’s overall size and presence, especially at night.

- Turn Signals: Indicate intended turns.

- Dashboard Gauges/Indicators: Provide real-time information to the driver (speedometer, tachometer, oil pressure, temperature, etc.).

Cab & Body Parts: Comfort and Functionality

The cab is the driver’s office, designed for comfort, safety, and functionality, while the body components protect and streamline the vehicle.

- Cab Structure: The main enclosure for the driver and passenger.

- Doors: Allow entry and exit from the cab.

- Hood (Bonnet): Covers the engine compartment, providing access for maintenance.

- Fenders: Cover the wheels, protecting the body from road debris.

- Grille: Front-mounted, allows airflow to the radiator.

- Bumper: Front and rear impact protection.

- Mirrors (Side Mirrors/Fender Mirrors): Provide rear and side visibility.

- Windshield/Windows: Provide visibility and enclose the cab.

- Seats: Driver and passenger seating, often air-ride for comfort.

- Dashboard/Instrument Panel: Houses gauges, controls, and infotainment systems.

- HVAC System (Heating, Ventilation, Air Conditioning): Maintains cab temperature and air quality.

- Sleeper Berth: An integrated sleeping compartment behind the cab for long-haul drivers.

Auxiliary & Specialized Components

These parts are often specific to heavy-duty trucks and their diverse applications.

- Fifth Wheel: The coupling device mounted on the tractor’s frame that connects to and supports a semi-trailer.

- Gladhands: Connectors for the air lines between the tractor and trailer (service and emergency air).

- Electrical Pigtail (7-Way Connector): Provides electrical connection for trailer lights and ABS.

- PTO (Power Take-Off): A mechanical device that draws power from the truck’s engine or transmission to operate auxiliary equipment (e.g., hydraulic pumps for dump trucks, cement mixers).

- Hydraulic Pump/Reservoir/Cylinders: Used for applications like dump beds, cranes, and liftgates.

- Exhaust System: Directs exhaust gases away from the engine, including:

- Muffler: Reduces exhaust noise.

- DPF (Diesel Particulate Filter): Traps soot from diesel exhaust.

- SCR (Selective Catalytic Reduction): Uses Diesel Exhaust Fluid (DEF) to reduce NOx emissions.

- Fuel Tanks: Store diesel fuel for the engine.

- DEF Tank (Diesel Exhaust Fluid Tank): Stores DEF for the SCR system.

Why Knowing Your Truck Parts Matters

Understanding truck part names offers numerous practical benefits:

- Effective Communication: Speak the same language as mechanics, parts suppliers, and fellow drivers. This ensures you get the right advice or the correct part the first time.

- Efficient Troubleshooting: When something goes wrong, knowing the potential components involved helps you narrow down the issue and describe symptoms accurately.

- Informed Maintenance: Recognize when a part needs attention or replacement, allowing for proactive maintenance that prevents costly breakdowns.

- Smarter Purchasing: Whether buying a new truck or replacement parts, an understanding of components helps you evaluate quality, compatibility, and value.

- Enhanced Safety: Familiarity with critical safety components (brakes, steering, lights) empowers you to perform thorough pre-trip inspections and identify potential hazards.

- Cost Savings: Avoid unnecessary repairs or incorrect part purchases by accurately diagnosing issues and specifying needs.

Tips for Learning and Identifying Truck Parts

Given the sheer volume of components, learning truck part names can seem daunting. Here are some practical tips:

- Start with the Basics: Focus on the major systems first (engine, drivetrain, brakes) and then delve into their sub-components.

- Utilize Your Owner’s Manual: This often contains diagrams and lists of parts specific to your truck model.

- Explore Online Resources: Websites, forums, YouTube channels, and digital parts catalogs are invaluable. Many provide detailed diagrams and exploded views.

- Visual Learning: Look at diagrams, visit truck shows, or spend time in a repair shop (if permitted) to see parts in person.

- Ask Questions: Don’t hesitate to ask mechanics or experienced drivers about parts you don’t recognize.

- Disassembly/Assembly Videos: Watching repair videos can help you see parts in context and understand their function.

- Categorize and Group: Learning parts by system (e.g., all brake parts together) makes retention easier.

Challenges and Solutions

The primary challenges in learning truck part names include the sheer number of components, variations between manufacturers and models, and the use of technical jargon.

- Challenge: Vast Number of Parts: A modern truck has thousands of individual components.

- Solution: Break it down. Focus on one system at a time. Prioritize critical components first.

- Challenge: Manufacturer/Model Variations: A "fuel filter" might look different or be located differently on a Volvo compared to a Freightliner.

- Solution: Understand the function first, then recognize common variations. Always refer to your specific truck’s service manual for precise information.

- Challenge: Technical Jargon and Acronyms: Terms like "ECM," "DPF," "SCR," or "PTO" can be confusing.

- Solution: Create a personal glossary. Look up unfamiliar terms immediately. Many online resources explain these acronyms.

Sample Price Guide for Common Truck Part Categories

It’s impossible to provide exact prices for all truck parts due to vast variations in make, model, year, brand (OEM vs. aftermarket), and market fluctuations. However, this table offers a general range for common replacement parts within different categories, serving as a guideline. Always obtain specific quotes for your vehicle.

| Part Category | Example Parts | General Price Range (USD) | Notes |

|---|---|---|---|

| Engine Components | Fuel Injector, Water Pump, Alternator, Turbo | $150 – $3,000+ | Injectors can be costly; turbos vary significantly by engine size. |

| Drivetrain Parts | Clutch Kit, Driveshaft U-Joint, Differential | $200 – $5,000+ | Clutch kits often include multiple components. Differentials are high-value. |

| Braking System | Brake Chamber, Brake Drum, Brake Pads (set) | $100 – $600+ | Prices per axle/wheel end. Air compressors are more expensive. |

| Suspension Parts | Air Spring (Air Bag), Shock Absorber, Leaf Spring | $150 – $800+ | Leaf springs can be replaced individually or as a pack. |

| Steering Components | Power Steering Pump, Tie Rod End, Steering Gearbox | $100 – $1,500+ | Steering gearboxes are complex and higher priced. |

| Electrical System | Battery, Starter Motor, Wiring Harness (small) | $100 – $500+ | Batteries are often sold in pairs for heavy trucks. |

| Cab & Body | Headlight Assembly, Side Mirror, Bumper Section | $150 – $1,000+ | Large body panels can be significantly higher. |

| Exhaust System | Muffler, DPF/SCR Filter (aftermarket) | $150 – $5,000+ | DPF/SCR units are among the most expensive emission components. |

| Auxiliary | Fifth Wheel Rebuild Kit, Gladhand | $50 – $500+ | Fifth wheel components vary from small repairs to major rebuilds. |

Note: These are estimated ranges for the part itself, excluding labor costs for installation, which can vary widely.

Conclusion

Understanding truck part names is more than just memorizing vocabulary; it’s about gaining a deeper appreciation for the complex engineering that goes into these indispensable vehicles. It empowers drivers, technicians, and owners to communicate effectively, diagnose problems accurately, make informed decisions, and ultimately, ensure the safe and efficient operation of their trucks. By systematically learning the components within each major system, utilizing available resources, and embracing continuous learning, anyone can become proficient in the language of truck parts. This knowledge is an investment that pays dividends in safety, reliability, and cost savings, keeping the wheels of commerce turning smoothly.

Frequently Asked Questions (FAQ) about Truck Part Names

Q1: Why is it important to know truck part names?

A1: Knowing truck part names is crucial for effective communication with mechanics and parts suppliers, accurate troubleshooting, performing proper pre-trip inspections, making informed purchasing decisions, and ensuring the overall safety and longevity of the vehicle.

Q2: Are truck part names universal across all brands (e.g., Freightliner, Kenworth, Volvo)?

A2: While the function of major components (e.g., engine, transmission, brakes) is universal, the specific design, part number, and exact name can vary significantly between manufacturers and even different models from the same manufacturer. Always refer to the specific truck’s owner’s manual or parts catalog.

Q3: Where can I find detailed diagrams of truck parts?

A3: Owner’s manuals, service manuals, online parts catalogs from manufacturers (e.g., PartsPro for Volvo/Mack, Daimler Trucks North America’s parts portals), and educational websites or YouTube channels dedicated to truck mechanics are excellent resources for diagrams and exploded views.

Q4: What’s the difference between OEM and aftermarket truck parts?

A4: OEM (Original Equipment Manufacturer) parts are made by the original company that supplied the parts to the truck manufacturer. They are generally higher priced but guarantee exact fit and quality. Aftermarket parts are produced by other companies as replacements for OEM parts. They can be more affordable but vary in quality and fit.

Q5: How can I identify a specific truck part if I don’t know its name?

A5: You can describe its location, shape, function, and any visible markings (like part numbers). Taking a clear photo or video is often the most helpful way to show a mechanic or parts supplier what you need. Online image searches can also be very useful.

Q6: Are there common acronyms for truck parts I should know?

A6: Yes, many! Some common ones include:

- ABS: Anti-lock Braking System

- ECM/ECU: Engine Control Module/Unit

- DPF: Diesel Particulate Filter

- SCR: Selective Catalytic Reduction

- DEF: Diesel Exhaust Fluid

- PTO: Power Take-Off

- HVAC: Heating, Ventilation, and Air Conditioning

Q7: Is it necessary for a truck driver to know all these part names, or just mechanics?

A7: While mechanics need in-depth knowledge for repairs, it’s highly beneficial for truck drivers to know at least the major components and their functions. This enables them to perform effective pre-trip inspections, communicate issues accurately, and potentially avoid costly breakdowns by recognizing early warning signs.