The Unsung Hero of Logistics: A Comprehensive Guide to the Flatbed Lorry Body

The Unsung Hero of Logistics: A Comprehensive Guide to the Flatbed Lorry Body cars.truckstrend.com

In the vast and varied world of commercial transportation, the lorry body is far more than just a container; it’s a specialized tool designed to meet specific cargo demands. Among the myriad options, the Flatbed Lorry Body stands out as one of the most versatile and indispensable configurations. Renowned for its open design and unparalleled flexibility, the flatbed is the workhorse of industries ranging from construction and agriculture to heavy haulage and specialized logistics.

This comprehensive guide will delve deep into the anatomy, benefits, applications, and critical considerations surrounding the flatbed lorry body. Whether you’re a fleet manager, a small business owner, or simply curious about the mechanics of modern transportation, understanding the nuances of the flatbed is key to appreciating its vital role in keeping our world moving.

The Unsung Hero of Logistics: A Comprehensive Guide to the Flatbed Lorry Body

What is a Flatbed Lorry Body? Defining its Role and Importance

At its core, a flatbed lorry body is a commercial vehicle platform characterized by a completely flat, open deck with no sides or roof. While some configurations might feature a fixed headboard at the front to protect the cab, the defining feature is the absence of enclosing structures. This seemingly simple design is precisely what grants it extraordinary utility.

The importance of the flatbed lies in its ability to transport oversized, irregularly shaped, or extremely heavy cargo that would be impractical or impossible to load into an enclosed trailer. From bundles of steel and timber to heavy machinery, pre-fabricated structures, and even other vehicles, the flatbed provides the unobstructed space and robust foundation required for securing diverse loads. It’s the ultimate solution for cargo that doesn’t fit neatly into a box, making it a cornerstone of construction projects, manufacturing supply chains, and specialized delivery services worldwide.

Anatomy of a Flatbed: Understanding Its Core Components

While appearing straightforward, a flatbed lorry body is engineered for strength, durability, and safety. Its primary components include:

- The Deck/Platform: This is the main load-bearing surface. Typically constructed from heavy-duty timber (like treated hardwood), steel, or aluminum, the deck must withstand immense pressure and resist abrasion. Its material choice often depends on the intended cargo and environmental conditions.

- Chassis Integration: The flatbed body is securely mounted onto the lorry’s chassis frame, which provides the structural backbone and houses the engine, drivetrain, and axles. The integrity of this mounting is paramount for stability and safety.

- Headboard (Optional but Common): Located at the front of the deck, directly behind the cab, the headboard acts as a protective barrier. It prevents cargo from shifting forward and potentially damaging the cab or injuring the driver during sudden braking. Headboards can vary in height and material, often incorporating mesh or solid steel.

- Side Rails and Tie-Down Points: Along the perimeter of the deck, sturdy side rails (often steel channels) are incorporated. Integrated into or attached to these rails are numerous tie-down points, such as D-rings, winch tracks, or stake pockets. These are crucial for attaching chains, straps, and binders to securely fasten the cargo, preventing movement during transit.

- Rub Rails (Optional): These are additional protective rails often found along the sides of the deck, designed to prevent damage to the flatbed itself or the cargo from external impacts.

- Under-Deck Storage (Optional): Some flatbeds incorporate toolboxes or storage compartments beneath the deck for securing equipment, straps, and other necessities.

The Unrivaled Advantages of the Flatbed Lorry Body

The widespread adoption of flatbeds is a testament to their distinct benefits:

- Unmatched Versatility: This is the flatbed’s strongest suit. It can accommodate virtually any type of cargo, regardless of its shape or size, provided it fits within legal weight and dimension limits.

- Ease of Loading and Unloading: With no confining walls or roof, cargo can be loaded and unloaded from any angle using cranes, forklifts, or even by hand, significantly reducing loading times and increasing operational efficiency.

- Accommodation of Oversized Cargo: For goods that exceed standard trailer dimensions – such as construction beams, large pipes, industrial machinery, or pre-fabricated housing modules – the flatbed is often the only viable transport solution.

- Robustness and Durability: Built to handle heavy and often abrasive loads, flatbeds are typically constructed from high-strength materials, ensuring a long service life even under demanding conditions.

- Lower Maintenance for the Body Itself: Compared to enclosed trailers with complex door mechanisms, refrigeration units, or curtain systems, the flatbed body has fewer moving parts, often leading to simpler and less frequent body-specific maintenance.

Types and Variations of Flatbed Lorry Bodies

While the basic concept remains the same, flatbeds come in several specialized variations:

- Standard Flatbed: The most common type, a simple, open platform.

- Drop-Side Flatbed: Features removable or hinged side panels (and sometimes a tailgate) that can be folded down or removed entirely. This offers the flexibility of a flatbed with the added security of sides for certain loads.

- Extendable Flatbed: Designed with a retractable section, allowing the bed length to be extended for exceptionally long cargo, such as bridge beams or wind turbine blades.

- Skeletal Flatbed (Container Chassis): Primarily used for transporting intermodal shipping containers. It consists of a bare frame designed to lock containers into place, often without a solid deck.

- Step Deck/Drop Deck Flatbed: Features a lower deck section behind the gooseneck (or directly behind the cab for rigid trucks), allowing for taller cargo to be transported while staying within height restrictions.

- Lowboy/Heavy Haul Flatbed: Extremely low-profile trailers designed for transporting exceptionally heavy and oversized equipment, often with multiple axles and specialized suspension.

Key Considerations When Choosing and Operating a Flatbed

Selecting and operating a flatbed requires careful thought to ensure safety, efficiency, and compliance.

- Load Capacity and Distribution: Always adhere to the lorry’s Gross Vehicle Weight (GVW) and Gross Combination Weight (GCW) ratings. Proper load distribution is critical to prevent instability, excessive axle loads, and potential structural damage. Overloading is illegal and extremely dangerous.

- Deck Material:

- Steel: Most durable, excellent for heavy, abrasive loads, but heavier and susceptible to rust without proper coating.

- Aluminum: Lighter, corrosion-resistant, improves fuel efficiency and payload capacity, but less resistant to impact damage than steel.

- Timber/Wood: Common for its grip and shock absorption, often combined with steel crossmembers. Requires periodic treatment and inspection for rot.

- Tie-Down Points and Securement Gear: Ensure sufficient, well-placed tie-down points are available. Invest in high-quality chains, binders, straps, edge protectors, and dunnage (blocking materials) appropriate for your cargo type.

- Safety Features: Consider features like robust headboards, anti-slip deck coatings, and accessible tie-down points for operator safety during loading and securing.

- Regulatory Compliance: Be acutely aware of local, national, and international regulations regarding load securement, weight limits, dimensions (especially for oversized loads requiring permits), and signage. Non-compliance can lead to hefty fines, delays, and accidents.

- Weather Protection: For weather-sensitive cargo, consider tarpaulins, shrink wrap, or other protective coverings. While a flatbed offers no inherent protection, these accessories can mitigate exposure.

Practical Advice: Operating and Maintaining Your Flatbed

Operating a flatbed isn’t just about driving; it’s about mastering the art of load securement and proactive maintenance.

- Load Securement is Paramount:

- Assess the Load: Understand its weight, dimensions, shape, and stability.

- Plan the Placement: Distribute weight evenly across the deck and axles. Keep the center of gravity as low as possible.

- Use Proper Gear: Employ chains for heavy, rigid items (e.g., machinery), and straps for lighter, more delicate, or compressible goods (e.g., timber). Use appropriate binders for chains.

- Apply Sufficient Tension: Ensure straps and chains are taut, but avoid over-tightening to prevent damage to the cargo or the flatbed.

- Protect Edges: Always use edge protectors to prevent straps/chains from cutting into the cargo or being abraded by sharp edges.

- Check and Re-check: Inspect securement before departure, after the first few miles, and periodically throughout the journey. Load shift is a major cause of accidents.

- Pre-Trip Inspections: Before every journey, conduct a thorough inspection:

- Check tires, brakes, lights, and reflectors.

- Inspect the deck for damage, cracks, or loose components.

- Verify the integrity of tie-down points.

- Ensure all securement devices are in good condition and correctly applied.

- Routine Maintenance:

- Keep the deck clean to prevent corrosion and maintain grip.

- Inspect welding seams and structural members for cracks or fatigue.

- Lubricate moving parts if applicable (e.g., extendable sections).

- Check and maintain the undercarriage, axles, and suspension components regularly.

- Address any rust spots promptly to prevent widespread corrosion.

Potential Challenges and Solutions

While versatile, flatbeds do present certain challenges:

- Load Shifting: The primary risk. Solution: Meticulous load securement, proper weight distribution, regular checks during transit, and driver training.

- Weather Exposure: Cargo is exposed to rain, snow, sun, and wind. Solution: Use tarpaulins, waterproof wraps, or specialized coatings for sensitive goods. Plan routes to avoid severe weather.

- Theft/Vandalism: Open cargo is more vulnerable. Solution: Secure valuable cargo with robust locks where possible, park in secure locations, and use GPS tracking.

- Aerodynamic Drag: Irregularly shaped loads can create significant drag, impacting fuel efficiency. Solution: While limited, optimizing load placement and using aerodynamic covers (if practical) can help.

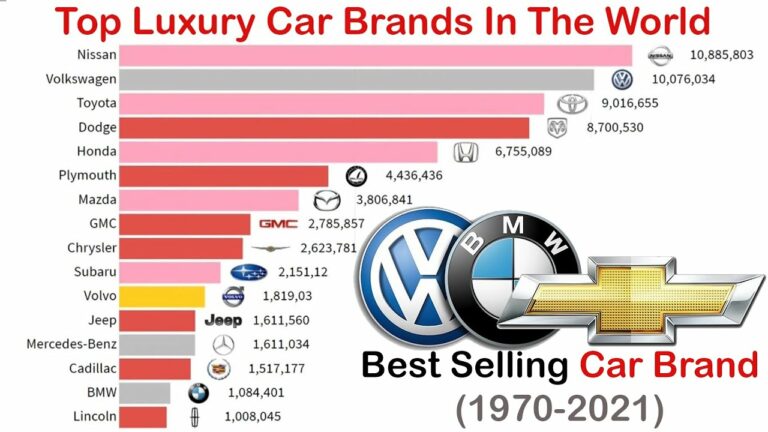

Pricing Guide: Flatbed Lorry Body

The cost of a flatbed lorry body varies significantly based on its size, material, features, and the manufacturer. This table provides estimated price ranges for common configurations (excluding the lorry chassis itself). Prices are indicative and can fluctuate based on market conditions, customization, and additional features.

| Body Type/Configuration | Material (Deck/Frame) | Length (m) | Width (m) | Estimated Load Capacity (Tonnes) | Key Features | Estimated Price Range (USD) |

|---|---|---|---|---|---|---|

| Light-Duty Standard | Steel/Timber | 4.0 – 6.0 | 2.2 – 2.5 | 3 – 8 | Fixed headboard, basic D-ring tie-downs, standard paint finish. Ideal for smaller rigid trucks (e.g., 7.5T – 12T GVW). | $5,000 – $12,000 |

| Medium-Duty Standard | Steel/Timber or Full Steel | 6.0 – 8.0 | 2.3 – 2.6 | 8 – 15 | Robust headboard, multiple tie-down points (D-rings, winch tracks), optional under-deck storage boxes, reinforced subframe. Suitable for 18T – 26T GVW rigid trucks. | $10,000 – $25,000 |

| Heavy-Duty Standard | Full Steel or Steel/Aluminum Composite | 8.0 – 10.0 | 2.4 – 2.7 | 15 – 30+ | Heavy-duty reinforced structure, extensive tie-down options, high-strength deck, integrated side markers, potential for specialized lighting. For 26T+ rigid trucks or semi-trailers. | $20,000 – $45,000+ |

| Drop-Side Flatbed | Steel/Timber or Full Steel | 5.0 – 8.0 | 2.3 – 2.6 | 5 – 15 | Removable/hinged drop sides (aluminum or steel), tailgate, standard headboard, versatile for various cargo types. | $12,000 – $30,000 |

| Extendable Flatbed | High-Tensile Steel | 12.0 – 20.0 (extended) | 2.5 – 2.7 | 20 – 40+ | Hydraulic extension system, multiple locking positions, robust outriggers for stability, specialized lighting, often for semi-trailers. | $40,000 – $80,000+ |

| Custom/Specialized | Varies | Varies | Varies | Varies | Designed for specific industry needs (e.g., pipe haulage, logging, equipment transport with ramps), may include bespoke features. | $30,000 – $100,000+ (highly variable) |

Note: These prices are estimates for the body only and do not include the cost of the lorry chassis, installation, delivery, taxes, or additional accessories like tarpaulins, specific securement gear, or specialized permits.

Frequently Asked Questions (FAQ) About Flatbed Lorry Bodies

Q1: What kind of cargo is best suited for a flatbed lorry?

A1: Flatbeds are ideal for oversized, irregularly shaped, heavy, or bulky items such as construction materials (timber, steel beams, pipes), machinery (tractors, excavators, forklifts), pre-fabricated structures, vehicles, industrial equipment, and large crates that don’t fit into enclosed trailers.

Q2: Are flatbeds safe for transporting goods?

A2: Yes, when operated correctly. Safety largely depends on proper load securement, even weight distribution, adherence to legal weight limits, and regular vehicle maintenance. Driver training in load securement techniques is crucial.

Q3: How do I protect cargo on a flatbed from weather?

A3: For weather-sensitive cargo, the primary method is to use heavy-duty tarpaulins, shrink wrap, or specialized covers. Ensure these are securely fastened to prevent flapping and damage during transit.

Q4: What’s the difference between a flatbed and a lowboy trailer?

A4: A standard flatbed has a deck that’s relatively high off the ground. A lowboy (or low-loader) is a specialized flatbed trailer with a much lower deck height, specifically designed to transport extremely tall and heavy equipment (like construction machinery) by keeping its overall height within legal limits.

Q5: Can I add sides to a standard flatbed?

A5: While a standard flatbed doesn’t come with sides, some manufacturers offer conversion kits or removable stake sides that fit into stake pockets along the deck. However, for regular use with sides, a "drop-side" flatbed is a more robust and purpose-built solution.

Q6: What materials are commonly used for flatbed decks?

A6: The most common materials are treated hardwood (like oak or apitong), steel (often checker plate or smooth), and aluminum. Each has pros and cons regarding weight, durability, grip, and cost. Often, a combination is used, such as a timber deck on a steel frame.

Conclusion: The Backbone of Heavy Haulage

The flatbed lorry body, in its elegant simplicity, remains an indispensable asset in the global logistics landscape. Its open design unlocks unparalleled versatility, enabling the transport of goods that are the very foundation of industries and infrastructure development. From the timber that builds homes to the machinery that shapes our world, the flatbed ensures these vital components reach their destination efficiently and safely.

Understanding the nuances of flatbed operations – from meticulous load securement to diligent maintenance and adherence to regulations – is not just about efficiency; it’s about safety on our roads. As technology advances, flatbeds continue to evolve with stronger materials and smarter securement systems, but their core purpose as the ultimate open-air transport solution will undoubtedly remain unchanged, solidifying their status as an unsung hero of modern commerce.