Parts Of Truck: A Comprehensive Guide to the Components That Keep the Wheels Turning

Parts Of Truck: A Comprehensive Guide to the Components That Keep the Wheels Turning cars.truckstrend.com

Trucks are the backbone of modern commerce and infrastructure, tirelessly hauling goods, materials, and equipment across vast distances. From local deliveries to cross-continental voyages, these mighty machines are marvels of engineering, designed for strength, durability, and relentless performance. But what exactly makes a truck tick? It’s a complex symphony of thousands of individual components, each playing a critical role in the vehicle’s overall function, safety, and efficiency. Understanding the "Parts Of Truck" is not just for mechanics; it’s essential for fleet managers, owner-operators, and anyone who relies on these powerful vehicles to appreciate their intricate design, optimize their operation, and ensure their longevity.

This comprehensive guide will delve into the various systems and components that constitute a truck, from its fundamental structure to the sophisticated electronics that govern its performance. We’ll explore the importance of each part, common types, maintenance considerations, and practical advice to help you navigate the world of truck parts with confidence.

Parts Of Truck: A Comprehensive Guide to the Components That Keep the Wheels Turning

The Foundation: Chassis and Frame

At the heart of every truck lies its chassis and frame, the robust skeletal structure that supports all other components and withstands the immense stresses of heavy loads and challenging terrains.

- Frame Rails: Typically made from high-strength steel, these are the primary longitudinal beams that run the length of the truck. They are designed to absorb and distribute weight and torsion.

- Crossmembers: Horizontal beams that connect the frame rails, providing rigidity and supporting various components like the engine, transmission, and suspension.

- Importance: The integrity of the frame is paramount for the truck’s structural stability, load-carrying capacity, and overall safety. Any damage to the frame can compromise the entire vehicle.

- Considerations: Different trucks use different frame types, from traditional ladder frames for heavy-duty applications to unibody constructions for lighter commercial vehicles. Regular inspection for cracks, bends, or corrosion is crucial.

The Driving Force: The Powertrain

The powertrain is the system responsible for generating and delivering power to the wheels, enabling the truck to move. It’s a complex assembly of interconnected components.

1. Engine

The heart of the truck, generating the power needed for propulsion.

- Types: Primarily diesel engines for heavy-duty trucks due to their fuel efficiency, torque output, and durability. Gasoline engines are common in lighter commercial vehicles.

- Key Components:

- Engine Block: The main structure housing cylinders, pistons, and crankshaft.

- Pistons & Connecting Rods: Convert combustion energy into mechanical motion.

- Crankshaft: Converts reciprocal motion of pistons into rotational motion.

- Cylinder Head: Houses valves, camshafts, and fuel injectors.

- Turbocharger/Supercharger: Boosts engine power by forcing more air into the cylinders.

- Fuel System: Fuel tank, fuel pump, injectors, filters.

- Cooling System: Radiator, water pump, thermostat, hoses – essential for dissipating heat.

- Exhaust System: Manifold, DPF (Diesel Particulate Filter), SCR (Selective Catalytic Reduction) system, muffler – manages exhaust gases and emissions.

- Maintenance Tips: Regular oil changes, filter replacements (oil, fuel, air), cooling system checks, and emissions system maintenance are vital for engine longevity and performance.

2. Transmission

Transfers power from the engine to the driveshaft, adjusting torque and speed.

- Types:

- Manual Transmissions: Offer more control and efficiency for experienced drivers, common in older or heavy-duty trucks.

- Automatic Transmissions: Provide ease of driving, increasingly popular in all truck segments.

- Automated Manual Transmissions (AMTs): Combine efficiency of manual with convenience of automatic.

- Components: Gears, shafts, synchronizers, clutch (for manual/AMT).

- Considerations: Proper fluid levels, timely filter changes, and adherence to service intervals are critical.

3. Driveshaft

A rotating shaft that transmits torque from the transmission to the differential in the axles.

- Components: U-joints (universal joints) allow for flexibility and angular changes.

- Importance: Must be balanced and free of damage to prevent vibrations and power loss.

4. Axles and Differential

- Axles: Support the vehicle’s weight and transmit driving power.

- Front Axle: Primarily for steering and sometimes braking.

- Rear Axle (Drive Axle): Receives power from the driveshaft and transmits it to the wheels. Heavy trucks often have multiple drive axles.

- Differential: A set of gears within the axle that allows wheels on the same axle to rotate at different speeds, crucial for turning.

- Maintenance: Differential fluid changes and inspection for leaks are important.

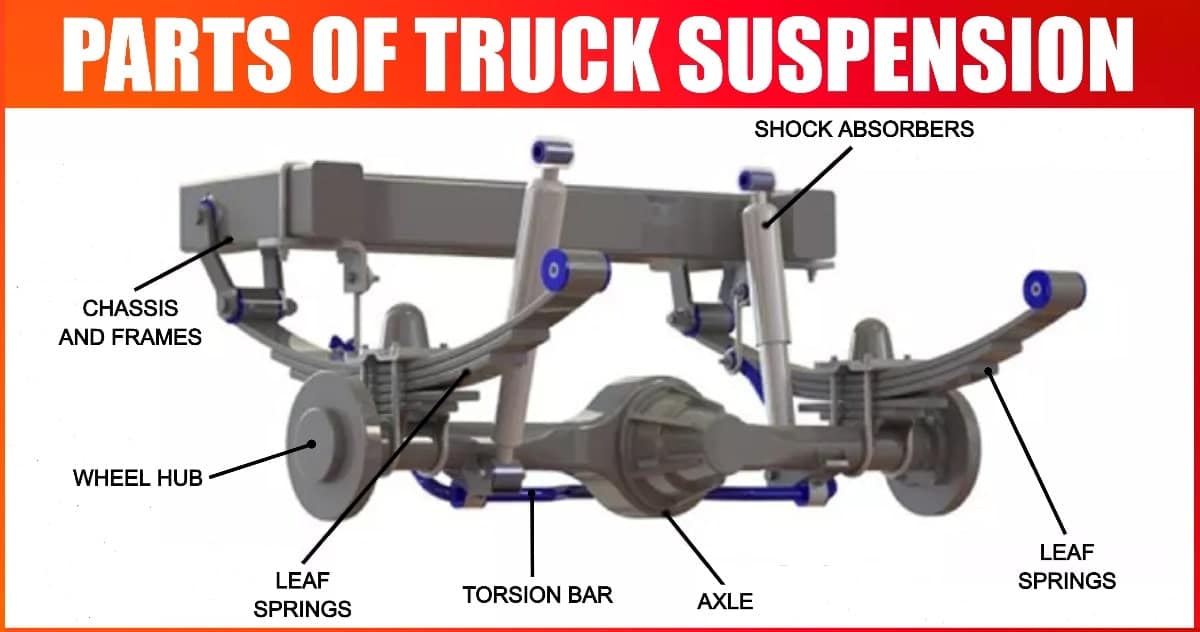

The Ride and Control: Suspension and Steering Systems

These systems ensure a smooth ride, stability, and precise control over the truck.

1. Suspension System

Absorbs shocks and bumps from the road, maintaining tire contact and stability.

- Components:

- Springs: Leaf springs (common for heavy loads), coil springs (lighter trucks), and increasingly, air springs (airbags) for superior ride quality and load leveling.

- Shock Absorbers/Dampers: Control spring oscillation, preventing excessive bouncing.

- Bushings: Rubber or polyurethane components that cushion joints and reduce vibration.

- U-bolts, Hangers, Shackles: Connect springs to the axle and frame.

- Benefits: Improved driver comfort, reduced cargo damage, better tire wear, and enhanced vehicle control.

- Challenges: Worn components can lead to poor handling, increased tire wear, and discomfort.

2. Steering System

Allows the driver to control the direction of the truck.

- Components:

- Steering Wheel & Column: Driver input.

- Steering Gearbox: Converts rotational motion to linear motion.

- Drag Link & Tie Rods: Connect the gearbox to the steering knuckles on the wheels.

- Power Steering Pump: Provides hydraulic assistance for easier steering.

- Importance: Precise and responsive steering is critical for safety and maneuverability, especially with heavy loads.

- Tips: Check power steering fluid levels and inspect for leaks regularly.

Safety First: The Braking System

Arguably the most critical safety system, enabling the truck to slow down and stop effectively. Heavy trucks typically use air brakes.

- Air Brake Components:

- Air Compressor: Generates compressed air.

- Air Tanks/Reservoirs: Store compressed air.

- Brake Lines & Valves: Distribute air pressure.

- Brake Chambers: Convert air pressure into mechanical force.

- Slack Adjusters: Automatically adjust brake shoe clearance.

- Brake Drums/Rotors: The rotating surfaces that brake shoes/pads press against.

- Brake Shoes/Pads: Friction material that creates braking force.

- ABS (Anti-lock Braking System): Prevents wheel lock-up during hard braking, maintaining steering control.

- Hydraulic Brakes: Found in lighter trucks, similar to passenger cars with master cylinder, brake fluid, and calipers.

- Maintenance: Regular inspection of air lines, chambers, and friction material (shoes/pads) is vital. Never compromise on brake maintenance.

Ground Contact: Wheels and Tires

The only parts of the truck that directly touch the road, influencing traction, handling, and fuel efficiency.

- Wheels (Rims):

- Materials: Steel (durable, heavy) or aluminum (lighter, better fuel economy, dissipates heat better).

- Types: Single-piece or multi-piece rims.

- Tires:

- Types: Radial (most common, better fuel economy, longer life) or bias-ply (older technology, less flexible).

- Tread Patterns: Optimized for various conditions (highway, off-road, all-season).

- Load Rating & Speed Rating: Crucial for safety and compliance.

- Tips: Proper tire pressure is paramount for safety, fuel efficiency, and tire longevity. Regular rotations, balancing, and alignment are also essential. Monitor tread depth and inspect for damage.

Powering the Electronics: The Electrical System

A complex network that powers everything from ignition to lighting and sophisticated onboard electronics.

- Components:

- Batteries: Provide initial power for starting and power when the engine is off. Heavy trucks typically use multiple large batteries.

- Alternator: Charges the batteries and powers electrical systems when the engine is running.

- Starter Motor: Engages the engine to start it.

- Wiring Harness: The intricate network of wires connecting all electrical components.

- Lights: Headlights, tail lights, brake lights, turn signals, marker lights – crucial for visibility and safety.

- ECU (Engine Control Unit) / ECM (Engine Control Module): The "brain" of the truck, managing engine performance, emissions, and other functions.

- Sensors: Monitor various parameters (temperature, pressure, speed) and feed data to the ECU.

- Challenges: Electrical issues can be complex to diagnose. Regular checks of battery terminals, wiring, and fuses are important.

The Driver’s Command Center: Cab and Interior Components

The cab is the driver’s office, designed for comfort, ergonomics, and safety during long hauls.

- Cab Types:

- Day Cab: For local operations, no sleeper berth.

- Sleeper Cab: Includes a bed and living space for long-distance drivers.

- Interior Components:

- Seats: Air-ride seats are common for superior comfort.

- Dashboard & Gauges: Provide vital information (speed, RPM, oil pressure, air pressure).

- Steering Wheel & Controls: Ergonomically designed for easy access.

- HVAC System: Heating, ventilation, and air conditioning for climate control.

- Infotainment & Communication Systems: Radios, GPS, ELDs (Electronic Logging Devices).

- Importance: A comfortable and well-equipped cab reduces driver fatigue, enhancing safety and productivity.

The Business End: Cargo/Load Carrying Components

These components are specialized based on the truck’s intended use for carrying cargo.

- For Tractors (Semi-trucks):

- Fifth Wheel: A large coupling device on the tractor’s frame that connects and locks to the kingpin of a semi-trailer, allowing articulation.

- For Straight Trucks:

- Flatbeds: Open platforms for oversized or irregular cargo.

- Box Bodies (Dry Vans): Enclosed cargo areas for general freight.

- Refrigerated Units (Reefers): Insulated box bodies with cooling systems for temperature-sensitive cargo.

- Dump Bodies: Hydraulically lifted beds for bulk materials like gravel or sand.

- Tankers: Cylindrical tanks for liquids or gases.

- Specialized Equipment: Cranes, liftgates, winches, etc., integrated into the truck body.

- Considerations: The design and maintenance of these components directly impact the efficiency and safety of cargo transport.

Maintenance and Replacement of Truck Parts

Understanding truck parts is incomplete without addressing their maintenance and eventual replacement.

- Importance of Genuine Parts: While aftermarket parts can be cheaper, OEM (Original Equipment Manufacturer) parts often offer superior quality, perfect fit, and come with warranties, ensuring optimal performance and safety.

- Regular Inspections: A consistent schedule of pre-trip, post-trip, and periodic inspections helps identify wear and tear early, preventing costly breakdowns.

- Common Wear and Tear Parts: Filters (oil, fuel, air), brake components, tires, belts, hoses, and suspension bushings are frequently replaced.

- DIY vs. Professional Repair: While minor replacements like filters can be DIY, complex repairs involving engines, transmissions, or braking systems require specialized tools, knowledge, and diagnostic equipment, best left to certified mechanics.

- Challenges: The cost of truck parts can be substantial. Sourcing genuine parts, especially for older or specialized trucks, can also be a challenge.

- Solutions: Implement a robust preventive maintenance program, build relationships with reputable parts suppliers, and consider extended warranties for major components.

Pricing Guide for Common Truck Parts

Please note: Prices are highly variable based on truck make/model, part brand (OEM vs. Aftermarket), supplier, and region. These are approximate ranges for illustrative purposes only.

| Part Category | Specific Part / Description | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Filtration | Engine Oil Filter | $20 – $60 | Essential for engine health. |

| Fuel Filter | $30 – $100 | Protects fuel injection system. | |

| Air Filter (Engine) | $50 – $150 | Crucial for engine performance and longevity. | |

| Cabin Air Filter | $20 – $50 | For HVAC system, driver comfort. | |

| Braking System | Brake Pads (set, heavy-duty) | $150 – $400 | For disc brakes. |

| Brake Shoes (set, heavy-duty) | $100 – $300 | For drum brakes. | |

| Brake Drum | $200 – $500 | Can be resurfaced or replaced. | |

| Brake Rotor (Disc) | $150 – $450 | For disc brakes. | |

| Brake Chamber | $100 – $250 | Air brake component. | |

| Engine & Powertrain | Alternator | $300 – $800 | Charges battery, powers electrical system. |

| Starter Motor | $250 – $700 | Starts the engine. | |

| Water Pump | $150 – $500 | Circulates coolant. | |

| Fuel Injector | $100 – $500 (each) | Varies greatly by type (diesel common rail injectors are expensive). | |

| Turbocharger | $1,000 – $5,000+ | Significant component, high cost. | |

| Clutch Kit (heavy-duty) | $800 – $2,500+ | Includes pressure plate, disc, release bearing. | |

| Suspension | Leaf Spring (single) | $150 – $400 | Varies by number of leaves and capacity. |

| Air Spring (Airbag) | $200 – $600 | For air suspension systems. | |

| Shock Absorber | $50 – $200 | Dampens spring oscillations. | |

| Suspension Bushings (each) | $10 – $50 | Small but critical for ride quality. | |

| Wheels & Tires | Commercial Truck Tire (single) | $300 – $700+ | Varies by size, type, and brand. |

| Steel Wheel (Rim) | $150 – $300 | Standard option. | |

| Aluminum Wheel (Rim) | $300 – $800+ | Lighter, better heat dissipation. | |

| Electrical & Lights | Heavy-Duty Battery (12V) | $150 – $300 | Truck typically uses 2-4 batteries. |

| Headlight Assembly (each) | $100 – $500+ | Varies by type (halogen, LED) and truck model. | |

| Taillight Assembly (each) | $50 – $200 | ||

| Steering | Power Steering Pump | $200 – $600 | Provides hydraulic assistance. |

| Tie Rod End | $50 – $150 | Connects steering linkage. |

Frequently Asked Questions (FAQ) about Truck Parts

Q1: How often should truck parts be inspected?

A1: Regular inspections are crucial. Daily pre-trip and post-trip inspections are mandatory for commercial vehicles. Beyond that, adhere to manufacturer-recommended service intervals, typically every 10,000-25,000 miles for minor services and more comprehensive checks at 50,000-100,000 miles. Key components like brakes, tires, and suspension should be checked more frequently.

Q2: What are the most common wear and tear parts on a truck?

A2: The most common wear and tear parts include:

- Filters (oil, fuel, air, cabin)

- Brake pads/shoes and drums/rotors

- Tires

- Belts and hoses

- Suspension components (bushings, shock absorbers, air springs)

- Clutch components (for manual transmissions)

- Batteries and electrical connectors

Q3: Is it better to use OEM (Original Equipment Manufacturer) or aftermarket parts?

A3: OEM parts are manufactured by the original company that made your truck’s components. They offer guaranteed fit, quality, and often come with a warranty. Aftermarket parts are made by other companies and can be cheaper, but quality and fit may vary. For critical safety components (brakes, steering) and major engine/transmission parts, OEM is generally recommended. For non-critical items, quality aftermarket parts can be a cost-effective option, but always source from reputable suppliers.

Q4: How can I find the right part for my specific truck?

A4: To ensure you get the correct part, always provide your truck’s VIN (Vehicle Identification Number) to the parts supplier. This unique code contains all the necessary information about your truck’s make, model, year, and specifications, allowing for accurate part identification. Also, note the specific engine type, transmission, and axle configurations.

Q5: What are the signs that a truck part needs replacement?

A5: Common signs include:

- Unusual Noises: Squealing brakes, grinding gears, clunking from suspension, engine knocking.

- Vibrations: Steering wheel shake, chassis vibration.

- Warning Lights: Dashboard indicators (check engine, ABS, low air pressure).

- Fluid Leaks: Puddles under the truck (oil, coolant, brake fluid, hydraulic fluid).

- Performance Issues: Reduced power, poor fuel economy, difficulty starting, spongy brakes, poor handling.

- Visible Wear: Cracks in tires, worn brake pads, corroded battery terminals, frayed belts.

Q6: Can I replace truck parts myself, or should I always go to a professional?

A6: Some minor parts replacements, like air filters or wiper blades, can be done by a knowledgeable individual. However, due to the complexity, weight, and safety-critical nature of many truck parts (e.g., brakes, engine components, suspension), professional mechanics with specialized tools and experience are highly recommended. Incorrect installation can lead to severe safety hazards and further damage.

Q7: How do I ensure the longevity of truck parts?

A7: Longevity is achieved through:

- Adhering to a Strict Maintenance Schedule: Regular oil changes, fluid checks, and filter replacements.

- Using Quality Parts and Fluids: Don’t cut corners on essential components.

- Proper Operation: Avoiding overloading, harsh braking, and aggressive driving.

- Addressing Issues Promptly: Don’t ignore warning signs; minor issues can quickly escalate.

- Cleanliness: Keeping the truck clean, especially underneath, can prevent corrosion.

Conclusion

The world of "Parts Of Truck" is vast and intricate, reflecting the engineering complexity required to build these workhorse vehicles. From the foundational frame to the sophisticated electronics, each component plays an indispensable role in ensuring a truck’s performance, safety, and efficiency. A comprehensive understanding of these parts, coupled with diligent maintenance practices and a proactive approach to replacements, is not merely about keeping a vehicle operational; it’s about safeguarding investments, ensuring driver safety, and maintaining the vital flow of goods and services that underpin our economy. By appreciating the meticulous design and interconnectedness of these components, we gain a deeper respect for the mighty trucks that keep our world moving forward.