Corresponding Cap: The Essential Guide to Perfect Fit and Protection

Corresponding Cap: The Essential Guide to Perfect Fit and Protection cars.truckstrend.com

In a world filled with intricate machinery, delicate components, and sensitive materials, the unsung hero often goes unnoticed: the Corresponding Cap. More than just a simple lid or cover, a Corresponding Cap is a precisely engineered closure designed to perfectly match and interface with a specific object, opening, or system. Its importance spans countless industries and everyday applications, providing critical protection, maintaining integrity, ensuring safety, and often contributing to the aesthetic appeal of a product.

From preventing leaks in a beverage bottle to safeguarding vital electronic ports or sealing industrial pipes, the Corresponding Cap plays a pivotal role in ensuring functionality and longevity. This comprehensive guide delves into the multifaceted world of Corresponding Caps, exploring their definition, diverse types, profound benefits, crucial selection criteria, and common challenges. Whether you’re an engineer, a product designer, or simply curious about the subtle yet significant elements of modern manufacturing, understanding the Corresponding Cap is key to appreciating the details that make our world work seamlessly.

Corresponding Cap: The Essential Guide to Perfect Fit and Protection

What is a Corresponding Cap?

At its core, a Corresponding Cap is a component designed with meticulous precision to fit, seal, or cover another specific component or opening. Unlike generic covers, its defining characteristic is this exact "correspondence" – a perfect match in terms of dimensions, thread type, material compatibility, and intended function. It’s not just about covering an opening; it’s about forming a secure, often hermetic, interface.

This precision is crucial. A cap that is too loose will fail to protect or seal effectively, leading to contamination, leaks, or damage. One that is too tight might be difficult to apply or remove, or could even damage the component it’s meant to protect. Therefore, the design and manufacturing of Corresponding Caps involve stringent adherence to specifications, ensuring a reliable and functional connection every time. They are found in myriad forms, from threaded closures on containers to snap-on protectors for sensitive electronics, each tailored to its unique application.

The Unseen Benefits of Precision: Why Corresponding Caps Matter

The seemingly simple function of a cap belies a host of significant advantages that contribute to product quality, safety, and operational efficiency.

- Superior Protection: The primary benefit. Corresponding Caps shield underlying components or contents from external elements such as dust, dirt, moisture, UV radiation, and physical impact. This extends the lifespan of sensitive equipment and maintains the purity of stored substances.

- Effective Sealing and Containment: For liquids, gases, or powders, a precisely fitted cap prevents leaks, evaporation, and contamination from the outside. In industrial settings, this ensures the integrity of fluid systems, preventing costly spills and environmental hazards.

- Enhanced Safety: By covering sharp edges, exposed electrical terminals, or hazardous materials, Corresponding Caps protect users and workers from injury. They can also be designed with tamper-evident features, offering an additional layer of security for products like pharmaceuticals or food.

- Preservation of Integrity: In applications like medical devices or sterile environments, Corresponding Caps maintain sterility and prevent airborne contaminants from compromising sensitive instruments or cultures.

- Aesthetic and Brand Consistency: Beyond function, a well-designed cap contributes to the overall appearance and perceived quality of a product. Consistent branding through custom caps reinforces corporate identity.

- Compliance with Regulations: Many industries have strict regulations regarding product containment, safety, and transport. Corresponding Caps are often integral to meeting these standards, ensuring products are fit for purpose and market.

Types and Applications of Corresponding Caps

The versatility of Corresponding Caps is evident in their wide array of types and applications across various sectors:

-

Industrial & Manufacturing Caps:

- Pipe End Caps: Used to protect the ends of pipes during storage, transport, and construction, preventing internal contamination and damage to pipe edges. Available in various materials (plastic, metal) and designs (push-in, threaded, flanged).

- Hydraulic & Pneumatic Caps: Essential for fluid power systems, these caps prevent contamination of ports and lines during assembly, maintenance, or storage, ensuring system cleanliness and longevity.

- Electrical Connector Caps: Designed to protect exposed electrical terminals, connectors, and cable ends from moisture, dust, corrosion, and accidental short-circuits.

- Valve Caps: Used on various types of valves (e.g., tire valves, gas cylinder valves) to prevent leakage, protect the valve mechanism, and keep out debris.

-

Consumer & Commercial Caps:

- Bottle & Container Caps: The most common type, ranging from screw caps for beverages and food to dispensing caps for lotions and sprays. Material choice (PP, HDPE, PET) depends on content compatibility and desired functionality.

- Lens Caps: Crucial for photographers and optical instrument users, these caps protect delicate camera lenses, binoculars, and telescopes from scratches, dust, and impact.

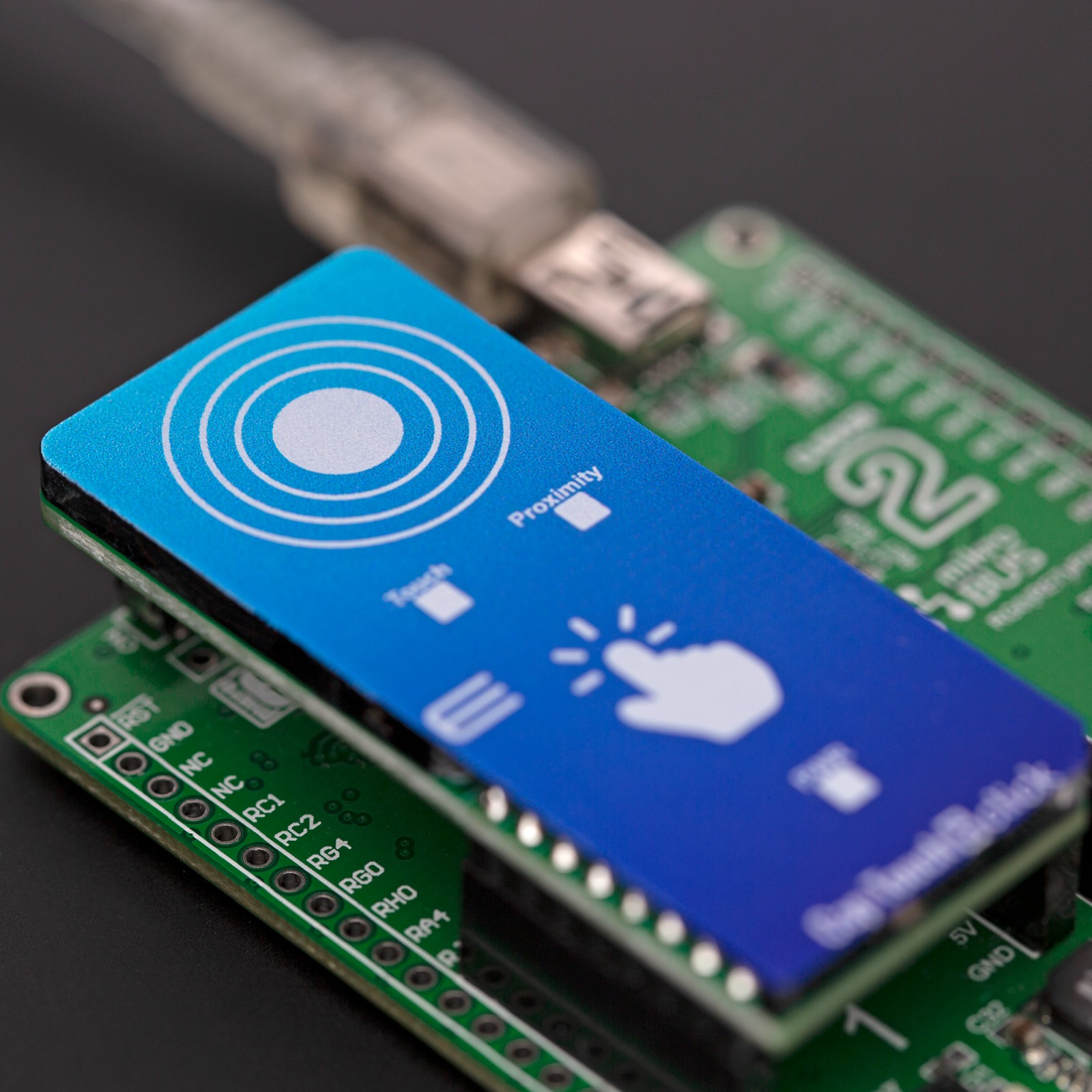

- Electronic Port Dust Caps: Small, often rubber or silicone caps that plug into USB, HDMI, audio, or network ports on electronic devices to prevent dust and debris ingress.

- Furniture & Fixture Caps: Used to cover exposed bolt heads, screw holes, or the ends of metal tubing (e.g., chair legs) for aesthetic purposes, safety, and floor protection.

-

Specialized & Niche Caps:

- Medical Device Caps: Used to maintain sterility and protect sensitive components of medical instruments, syringes, and diagnostic equipment. Often made from medical-grade, autoclavable materials.

- Automotive Caps: Found throughout vehicles, protecting fluid reservoirs (e.g., brake fluid, engine oil), battery terminals, and various sensor ports from environmental factors.

- Shipping & Transit Caps: Designed for temporary protection of delicate parts or assemblies during transportation, ensuring they arrive at their destination undamaged.

Choosing the Right Corresponding Cap: A Practical Guide

Selecting the appropriate Corresponding Cap is critical for optimal performance and cost-effectiveness. Consider the following factors:

- Material Compatibility: The cap material must be compatible with the substance it contains or the environment it will be exposed to.

- Plastics (HDPE, LDPE, PVC, Polypropylene, Nylon, Silicone): Lightweight, cost-effective, good chemical resistance for many applications. Silicone offers excellent temperature resistance and flexibility.

- Metals (Steel, Aluminum, Brass): Durable, high temperature resistance, suitable for high-pressure or corrosive industrial environments.

- Rubber: Excellent sealing properties, flexibility, and vibration dampening.

- Fit and Dimensions: This is paramount. Accurately measure the inner diameter (ID), outer diameter (OD), thread type (if applicable – e.g., NPT, metric, custom), and depth of the opening or component the cap needs to correspond to. Even slight discrepancies can compromise sealing or retention.

- Environmental Conditions: Consider the operating temperature range, exposure to UV light, moisture, chemicals, and abrasive materials. A cap designed for indoor use may rapidly degrade outdoors.

- Application Requirements:

- Sealing Type: Does it need to be airtight, watertight, or just dust-proof?

- Pressure/Vacuum: Will the cap need to withstand internal or external pressure differentials?

- Reusability: Is the cap designed for single use or multiple applications?

- Sterility: Is a sterile or medical-grade cap required?

- Ease of Use: How easily should it be applied and removed?

- Regulatory Compliance: For food, medical, or hazardous material applications, ensure the cap material and design comply with relevant industry standards (e.g., FDA, ISO, ASTM).

Common Challenges and Solutions

While Corresponding Caps are designed for reliability, challenges can arise:

- Mismatched Fit: The most common issue, leading to leaks, inadequate protection, or difficulty in application/removal.

- Solution: Implement rigorous measurement protocols and quality control during procurement. Work with suppliers who offer precise sizing guides and samples.

- Material Degradation: Caps can crack, warp, or become brittle due to exposure to chemicals, extreme temperatures, or UV radiation over time.

- Solution: Select materials specifically rated for the expected environmental conditions and chemical exposure. Consider caps with UV inhibitors for outdoor use.

- Loss or Misplacement: Small caps, especially those for electronic ports or industrial fittings, are easily lost.

- Solution: Utilize caps with integrated lanyards, tethers, or chains that keep them attached to the component. Implement organized storage solutions for spare caps.

- Difficulty of Removal/Attachment: Caps that are too tight or lack ergonomic features can be hard to handle, especially in repetitive operations or with gloved hands.

- Solution: Opt for caps with knurled edges, tabs, or easy-grip designs. For highly secure applications, specialized tools might be necessary, but balance security with practicality.

- Contamination During Application: Improper handling can introduce contaminants to the protected area even with a clean cap.

- Solution: Implement clean handling procedures, especially for sensitive applications. Use gloves and work in clean environments where necessary.

Corresponding Cap Price Table

The price of Corresponding Caps varies significantly based on material, size, design complexity, specialized features, and order quantity. Below is a general price range for common types (prices are indicative and subject to market fluctuations and bulk discounts).

| Cap Type | Material Examples | Size Range (Nominal) | Typical Unit Price (USD) | Key Features / Notes |

|---|---|---|---|---|

| Small Dust Caps | LDPE, Silicone, Rubber | 3mm – 20mm (ID/OD) | $0.05 – $0.50 | For electronic ports, small tubing; often push-in. |

| Standard Bottle Caps | PP, HDPE, PET | 20mm – 40mm (Neck Fin.) | $0.08 – $0.75 | Screw-on, snap-on; tamper-evident, dispensing options. |

| Industrial Pipe Caps | HDPE, Nylon, Carbon Steel | 1/2" – 6" (NPS) | $0.50 – $15.00 | Push-in, threaded, flanged; for pipe protection. |

| Hydraulic/Pneumatic Caps | HDPE, PP, Nylon | 1/8" – 2" (Port Size) | $0.20 – $5.00 | Prevents contamination in fluid power systems. |

| Electrical Connector Caps | Silicone, Rubber, Nylon | Varies by connector | $0.30 – $8.00 | Environmental sealing for terminals/connectors. |

| Specialized/High-Perf. | PTFE, Viton, Stainless Steel | Custom sizes | $5.00 – $50.00+ | Medical-grade, high temp/pressure, chemical resistant. |

Note: Bulk orders often result in significant per-unit price reductions. Custom tooling for unique cap designs will incur additional costs.

Frequently Asked Questions (FAQ)

Q1: How do I measure for the correct cap size?

A1: For internal caps (fitting into an opening), measure the inner diameter (ID) of the opening. For external caps (fitting over an object), measure the outer diameter (OD) of the object. For threaded caps, you’ll also need the thread type and pitch. It’s always best to consult the manufacturer’s specifications or use a caliper for precise measurement.

Q2: What’s the difference between threaded and non-threaded caps?

A2: Threaded caps feature internal or external threads that screw onto or into a corresponding threaded component, providing a secure, often pressure-resistant seal. Non-threaded caps (like push-in, friction-fit, or snap-on caps) rely on a tight tolerance or a specific design feature (e.g., barbed ribs) to hold them in place, offering quicker application but generally less secure sealing.

Q3: Can Corresponding Caps be reused?

A3: It depends on the cap’s design, material, and application. Many consumer caps (like bottle caps) are single-use due to material deformation or tamper-evident features. Industrial caps, especially those made from durable plastics or metals, are often designed for multiple uses, provided they remain undamaged and maintain their fit.

Q4: How do I clean a Corresponding Cap?

A4: Cleaning methods vary by material. Most plastic and rubber caps can be cleaned with mild soap and water. For industrial or medical caps, specific cleaning agents or sterilization protocols (e.g., autoclaving for medical-grade silicone) may be required. Always avoid harsh chemicals that could degrade the material.

Q5: Are there eco-friendly options for Corresponding Caps?

A5: Yes, the industry is increasingly offering sustainable options. These include caps made from recycled plastics (PCR – Post-Consumer Recycled), bio-based plastics (derived from renewable resources), or biodegradable materials. Reusable cap designs also contribute to reducing waste.

Conclusion

The Corresponding Cap, often overlooked, is a testament to the power of precision engineering and thoughtful design. Far from being a mere accessory, it is a critical component that safeguards valuable assets, ensures operational integrity, and contributes significantly to the safety and longevity of countless products and systems. From the smallest electronic port protector to robust industrial pipe closures, their perfect "correspondence" is what makes them indispensable.

Understanding the various types, material properties, and application requirements of Corresponding Caps empowers you to make informed decisions that enhance product performance, reduce waste, and improve safety. Investing in the right Corresponding Cap is not just about a purchase; it’s about securing the reliability and extending the lifespan of what it protects, underscoring its vital role as an unsung hero in our engineered world.