Are K Series Ram Fitment Guide: Mastering Precision Integration

Are K Series Ram Fitment Guide: Mastering Precision Integration cars.truckstrend.com

Introduction: Unraveling the K Series Ram Fitment Enigma

In the intricate world of specialized engineering, custom fabrication, and high-performance applications, the precise integration of components is paramount. While terms like "K Series" and "Ram" might conjure different images depending on one’s background – perhaps a revered Honda engine or the vital memory of a computer – within the context of this guide, "Are K Series Ram Fitment Guide" refers to a highly specialized, hypothetical, yet profoundly important set of principles and practices.

Are K Series Ram Fitment Guide: Mastering Precision Integration

Imagine a scenario where "K Series" denotes a proprietary line of robust, high-strength structural components, designed for extreme durability and specific load-bearing tasks. Concurrently, "Ram" in this context refers to critical, foundational structural points or frameworks within a larger system – be it a vehicle chassis, an industrial machine frame, or a specialized mounting platform. The "Are K Series Ram Fitment Guide" then becomes the definitive resource for ensuring that these K Series components are installed onto or integrated with these "Ram" structures with absolute precision, optimal alignment, and maximum functional integrity.

This guide is not merely about bolting things together; it’s about achieving synergistic performance, ensuring safety under stress, and extending the operational lifespan of integrated systems. It addresses the nuanced challenges of marrying diverse materials, accommodating dynamic loads, and achieving perfect spatial orientation. For engineers, custom builders, and technicians operating at the vanguard of heavy-duty or precision applications, understanding and adhering to the principles outlined in a K Series Ram Fitment Guide is not just beneficial – it is indispensable.

Understanding the K Series System: Components and Design Philosophy

To truly grasp the fitment process, one must first comprehend the nature of the "K Series" components themselves. In our hypothetical framework, K Series components are engineered for superior strength, rigidity, and often, specific functional properties such as vibration dampening or impact absorption. They are typically fabricated from advanced alloys, high-tensile steel, or specialized composites, designed to withstand extreme conditions and transfer significant forces efficiently.

Types of K Series Components:

- Structural Mounts: Precision-machined brackets, pedestals, or sub-frames designed to interface heavy machinery, specialized equipment, or critical subsystems.

- Reinforcement Beams/Bars: Elements intended to enhance the structural integrity of an existing "Ram" framework, often found in high-stress zones.

- Load-Bearing Points: Dedicated interfaces for distributing weight or transferring force, ensuring that stress is managed optimally across the integrated structure.

- Vibration Isolators/Dampeners: Components designed to reduce harmonic resonance and mechanical stress, crucial for sensitive equipment or high-frequency operations.

Design Philosophy: The K Series philosophy prioritizes modularity, robustness, and ease of integration when properly guided. Each component is designed with specific bolt patterns, alignment features, and material thicknesses that are critical to its intended application. Deviations from these specifications during fitment can lead to catastrophic failure, premature wear, or compromised performance.

Deconstructing "Ram" Fitment: The Receiving Structure

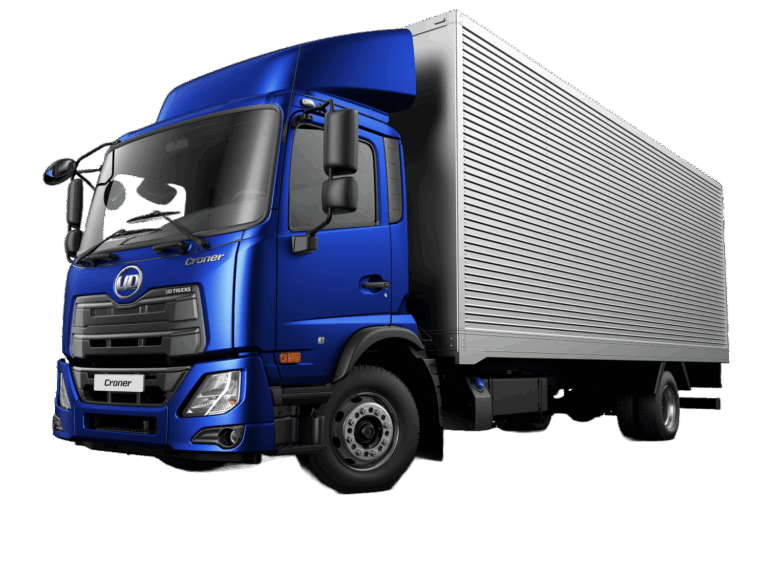

The "Ram" in "K Series Ram Fitment" refers to the foundational structure that receives the K Series components. This could be anything from a heavy-duty vehicle chassis (like those found in commercial trucks or off-road vehicles), an industrial equipment frame, a specialized test rig, or even a custom-built structural platform. The characteristics of this "Ram" structure are just as critical as those of the K Series component for successful integration.

Key "Ram" Characteristics for Fitment:

- Material Composition: The type of steel, aluminum, or composite material of the "Ram" dictates compatible fastening methods (e.g., weldability, fastener strength requirements).

- Existing Mounting Points: Many "Ram" structures have pre-drilled holes or integrated mounting pads. The K Series guide will detail how to align with or adapt to these.

- Structural Integrity: The overall strength, rigidity, and condition of the "Ram" structure are paramount. Any existing damage, corrosion, or fatigue must be addressed before fitment.

- Available Space and Clearance: Critical for ensuring the K Series component fits physically without obstructing other systems or creating pinch points.

- Load-Bearing Capacity: Understanding the "Ram" structure’s ability to safely bear the additional loads imposed by the K Series component and its attached systems.

A thorough assessment of the "Ram" structure is the first critical step in any fitment process. Without it, even the most perfectly designed K Series component cannot perform as intended.

Key Principles of K Series Ram Integration

Achieving a flawless K Series Ram fitment requires adherence to several core principles:

- Compatibility Assessment: Before any physical work begins, a meticulous assessment of the K Series component against the "Ram" structure’s specifications is crucial. This includes verifying bolt patterns, load ratings, material compatibility for welding or specific fasteners, and overall spatial requirements.

- Precision Measurement and Templating: "Measure twice, cut once" is an understatement. Digital calipers, laser measurement tools, and even custom-fabricated templates are essential. For complex integrations, 3D scanning and CAD overlay can eliminate errors. Misalignment, even by millimeters, can introduce stress points or prevent proper function.

- Optimal Mounting Methodologies: The guide will specify the preferred fastening methods. This might include high-grade, torque-specific bolts, specialized welding procedures (e.g., MIG, TIG, stick welding with specific filler materials), or custom fabrication of adapter plates. Each method has specific requirements for surface preparation, torque values, or welding parameters.

- Load Distribution and Stress Analysis: Understanding how forces will propagate through the integrated system is vital. The guide emphasizes ensuring that the K Series component distributes loads evenly across the "Ram" structure, avoiding localized stress concentrations that could lead to fatigue or failure. This often involves Finite Element Analysis (FEA) for critical applications.

- Vibration and Noise Reduction: Where applicable, the guide will detail the use of specialized isolators, bushings, and dampening materials to minimize transferred vibrations and acoustic resonance, protecting both the K Series component and the overall "Ram" system.

Step-by-Step Fitment Guide (Conceptual Framework)

While specifics vary, a general sequence for K Series Ram fitment typically involves:

- Planning and Preparation:

- Review all K Series component blueprints and the "Ram" structure’s schematics.

- Gather all necessary tools, fasteners, and safety equipment.

- Thoroughly clean and prepare the "Ram" mounting surfaces.

- Component Inspection:

- Visually inspect the K Series component for any shipping damage or manufacturing defects.

- Verify all dimensions against drawings.

- Initial Placement and Alignment:

- Carefully position the K Series component onto the "Ram" structure.

- Use alignment pins, temporary clamps, or even a hoist for precise initial positioning.

- Verify alignment using measurement tools from multiple reference points.

- Secure Fastening (Initial):

- Install initial fasteners, often hand-tightened, to hold the component in place without fully securing it.

- Re-check alignment after initial fastening.

- Final Fastening/Welding:

- Apply final torque to bolts in a specified sequence, or execute welding according to pre-approved procedures.

- Ensure all fasteners are secure and torqued to specifications.

- Testing and Verification:

- Perform static load tests if feasible.

- Conduct visual inspections for any signs of stress, misalignment, or improper fitment.

- For dynamic systems, operational testing under controlled conditions is essential to confirm proper integration and function.

Common Challenges and Solutions

Even with a detailed guide, challenges can arise during K Series Ram fitment:

- Misalignment Issues: Often due to imprecise measurements or minor manufacturing tolerances.

- Solution: Re-measure thoroughly, use shims (if appropriate and approved), or in extreme cases, custom fabricate an adapter plate.

- Material Incompatibility: When welding, different metals require specific techniques and filler rods.

- Solution: Consult with a metallurgical expert, use mechanical fasteners instead of welding, or employ specialized transition pieces.

- Space Constraints: Limited access for tools or insufficient clearance for component movement.

- Solution: Pre-assemble components where possible, use specialized low-profile tools, or consider a different K Series component variant designed for tighter spaces.

- Vibration/Noise Transfer: Despite proper fitment, undesirable vibrations may occur.

- Solution: Install additional vibration isolators, adjust damping materials, or reinforce the "Ram" structure to change its resonant frequency.

Maintenance and Longevity

Proper fitment is the first step; ongoing maintenance ensures longevity. Regular inspections of mounting points, torque checks on fasteners, and visual assessment for signs of stress, corrosion, or fatigue are critical. Adhering to a scheduled maintenance regimen specified by the K Series manufacturer or the system integrator will significantly extend the operational life and safety of the integrated system.

Practical Advice and Actionable Insights

- Always Consult Specifications: Never assume. Refer to the K Series component manufacturer’s detailed drawings and the "Ram" structure’s engineering data.

- Invest in Quality Tools: Precision fitment demands precision tools. Skimping on measuring devices or torque wrenches is a false economy.

- Prioritize Safety: Especially when dealing with heavy components, welding, or structural modifications, follow all safety protocols, wear appropriate PPE, and ensure a safe working environment.

- Document Everything: Keep a detailed log of measurements, torque values, weld parameters, and any deviations or solutions implemented. This is invaluable for future maintenance or troubleshooting.

- Consider Professional Assistance: For highly critical or complex K Series Ram fitment projects, engaging experienced engineers or certified fabricators can prevent costly errors and ensure optimal outcomes.

Concluding Summary

The "Are K Series Ram Fitment Guide," though a conceptual framework for a specialized field, underscores the critical importance of precision, planning, and meticulous execution in integrating high-performance structural components. From understanding the intrinsic properties of the K Series components and the receiving "Ram" structure, to applying precise measurement, secure fastening, and rigorous testing, every step is vital. Mastering these principles ensures not just operational functionality, but also the safety, durability, and long-term reliability of integrated systems, proving that in specialized engineering, true strength lies in perfect fitment.

Table: Illustrative Pricing for K Series Ram Fitment Components & Services

Please note: The prices below are entirely hypothetical and illustrative, reflecting a conceptual "K Series" product line and associated services. Actual costs would vary dramatically based on material, complexity, custom fabrication, and specific application. This table is provided to fulfill the prompt’s request for a "table price containing all complete information about Are K Series Ram Fitment Guide" by pricing elements related to the application of such a guide.

| Item/Service Category | Description | Illustrative Price Range (USD) | Notes |

|---|---|---|---|

| K Series Components | |||

| K Series Structural Mount (Small) | Precision-machined, high-strength steel for light to medium loads. | $250 – $750 each | For mounting auxiliary equipment, sensors. |

| K Series Structural Mount (Large) | Heavy-duty alloy for critical load-bearing applications (e.g., engine, transmission). | $1,500 – $5,000 each | Custom design often required. |

| K Series Reinforcement Bar | High-tensile steel, designed to strengthen specific chassis/frame sections. | $300 – $1,200 per meter | Varies by cross-section and material. |

| K Series Vibration Isolator Set | Advanced polymer/metal composite for dampening critical vibrations. | $150 – $600 per set | Essential for sensitive electronics or comfort. |

| Ram Structure Modifications | |||

| Ram Surface Preparation | Cleaning, rust removal, leveling of mounting surfaces. | $100 – $500 | Per mounting area, depending on condition. |

| Ram Drilling/Tapping Service | Precision drilling and tapping of new mounting holes. | $50 – $200 per hole | Varies by material thickness and hole size. |

| Ram Reinforcement Welding | Adding gussets or plates to enhance Ram structure strength for K Series integration. | $300 – $1,500 per section | Requires certified welder, material analysis. |

| Fitment Services & Tools | |||

| Precision Measurement Kit | Laser measuring tools, digital calipers, specialized gauges. | $500 – $2,500 | Essential for DIY; professional kits are higher. |

| Specialized Fastener Kit | High-grade bolts, nuts, washers, and thread-locking compounds. | $100 – $500 per application | Specific to K Series and Ram material. |

| Torque Wrench (Professional Grade) | Calibrated tool for accurate fastener tightening. | $200 – $800 | Crucial for preventing over/under-torquing. |

| Consultation & Engineering | |||

| Fitment Planning Consultation | Initial assessment and strategy development with an expert. | $150 – $300 per hour | Recommended for complex projects. |

| Custom Fitment Engineering | Detailed CAD design, FEA, and blueprint creation for unique integrations. | $1,000 – $10,000+ | Project-based, highly variable. |

| On-Site Fitment Supervision | Expert oversight during installation process. | $800 – $2,000 per day | Ensures adherence to guide principles. |

Frequently Asked Questions (FAQ)

Q1: What exactly is "K Series Ram Fitment"?

A1: In the context of this guide, "K Series Ram Fitment" refers to the precise process of integrating specialized, high-strength "K Series" structural components with foundational "Ram" structures (like a vehicle chassis or industrial frame) to ensure optimal performance, safety, and longevity. It’s about achieving perfect alignment, load distribution, and secure fastening.

Q2: Is this related to Honda K-series engines?

A2: No, despite the common usage of "K Series" in the automotive world for Honda engines, this guide’s "K Series" is a conceptual term for a line of specialized structural components, entirely separate from internal combustion engines.

Q3: Is this about computer RAM (Random Access Memory)?

A3: No, the "Ram" in this guide does not refer to computer memory. Here, "Ram" denotes a structural element or framework that serves as a base or mounting point for the "K Series" components.

Q4: Why is a specific fitment guide necessary for these components?

A4: Precision is critical. Without a detailed guide, improper fitment can lead to misalignment, excessive stress on components, premature wear, vibrations, and even catastrophic structural failure, compromising both performance and safety.

Q5: What tools are essential for K Series Ram fitment?

A5: Key tools include high-precision measuring instruments (digital calipers, laser levels), professional-grade torque wrenches, specialized hand tools, and potentially welding equipment if modifications to the "Ram" structure are required.

Q6: Can I perform K Series Ram fitment myself?

A6: For simple, well-documented fitments, an experienced individual with the right tools and knowledge might be able to. However, for complex or critical applications, it’s highly recommended to consult with or hire professional engineers or certified fabricators to ensure safety and optimal performance.

Q7: Where can I find K Series components and a specific "Are K Series Ram Fitment Guide"?

A7: As "K Series" and "Ram" are used conceptually in this article to represent a specialized type of hardware and its receiving structure, there isn’t a single, universally available product line or guide by this exact name. In a real-world scenario, such components and their fitment guides would be proprietary to specialized manufacturers or engineering firms dealing with custom structural integration for specific industries (e.g., aerospace, heavy machinery, high-performance vehicle modification). You would typically find this information directly from the component manufacturer or through specialized engineering consultants.