Empty Food Truck Trailer For Sale: Your Blueprint for Mobile Culinary Success

Empty Food Truck Trailer For Sale: Your Blueprint for Mobile Culinary Success cars.truckstrend.com

The dream of owning a food truck often conjures images of gleaming stainless steel, sizzling grills, and lines of hungry customers. While a fully equipped food truck can be an exhilarating venture, the initial investment can be daunting. This is where the concept of an "empty food truck trailer for sale" emerges as a powerful, cost-effective, and incredibly flexible alternative. Far from being just an empty shell, these trailers represent a blank canvas—a foundational step that empowers aspiring culinary entrepreneurs to custom-design their mobile kitchen from the ground up, aligning every detail with their unique vision and budget.

An empty food truck trailer is essentially a mobile unit designed to be towed, providing a sturdy, enclosed space ready for customization. It comes without the internal kitchen equipment, plumbing, or electrical systems typically found in a ready-to-operate unit. For many, this isn’t a limitation but rather an opportunity. It signifies lower upfront costs, unparalleled freedom in layout and equipment selection, and the chance to build a food truck truly tailored to a specific cuisine, workflow, and aesthetic. This comprehensive guide will walk you through everything you need to know about finding, evaluating, and transforming an empty food truck trailer into a thriving mobile culinary business.

Empty Food Truck Trailer For Sale: Your Blueprint for Mobile Culinary Success

Why Choose an Empty Food Truck Trailer? The Undeniable Advantages

Opting for an empty food truck trailer offers a compelling set of benefits, particularly for startups and those with a clear vision:

- Cost-Effectiveness: This is arguably the most significant advantage. An empty trailer typically costs significantly less than a pre-built or used fully equipped food truck. This allows you to allocate more of your initial capital towards high-quality kitchen equipment, marketing, or working capital.

- Unrivaled Customization: When you start with an empty shell, you have complete control over the interior layout, equipment placement, and aesthetic design. You can optimize the space for your specific menu, ensure ergonomic workflow, and install only the equipment you truly need, avoiding costly removals or modifications of existing setups.

- Quality Control: Building from scratch means you choose every component, from the wiring and plumbing to the insulation and wall materials. This ensures that everything meets your quality standards and local health and safety codes, minimizing potential issues down the line.

- Scalability and Phased Investment: You can start with essential equipment and gradually add more specialized items as your business grows and your budget allows. This phased approach can make the initial investment more manageable.

- Learning Opportunity: For first-time food truck owners, building out a trailer can provide invaluable hands-on experience and a deeper understanding of how their mobile kitchen functions, which can be beneficial for maintenance and troubleshooting.

- Focus on Core Business: Instead of inheriting someone else’s problems or compromising on a less-than-ideal layout, you can focus your energy on developing your menu, perfecting your recipes, and planning your business operations from day one.

What to Look For: Key Considerations When Buying an Empty Trailer

Purchasing an empty trailer requires a keen eye and a thorough inspection. Here’s a checklist of critical factors to evaluate:

- Size and Layout Potential:

- Length and Width: Does it offer enough interior space for your planned equipment, prep areas, and multiple staff if needed? Common lengths range from 8 to 24 feet.

- Ceiling Height: Ensure sufficient headroom for comfortable working, especially if you or your staff are tall. Adequate height is also crucial for installing ventilation hoods.

- Existing Openings: Are there pre-cut serving windows or side doors? If not, consider the cost and feasibility of adding them.

- Structural Integrity (The Shell Itself):

- Frame and Chassis: Inspect for rust, bends, cracks, or any signs of structural fatigue. A solid frame is paramount for safety and longevity.

- Walls, Roof, and Floor: Look for dents, punctures, leaks, water damage, or significant corrosion. The floor should be sturdy and capable of supporting heavy kitchen equipment.

- Insulation: While often bare, check if any existing insulation is intact or if it needs to be completely redone.

- Running Gear (Axles, Tires, Brakes):

- Axles: Check for straightness and signs of damage. Ensure the weight rating is sufficient for the loaded trailer.

- Tires: Inspect tread depth, sidewall condition, and age. Don’t forget to check the spare tire.

- Braking System: Verify the functionality of electric or hydraulic brakes. This is critical for safe towing, especially with heavy loads.

- Hitch and Coupler: Ensure the coupler is in good condition and compatible with your tow vehicle. Check safety chains and electrical connections.

- Pre-existing Utilities (If Any): Some empty trailers might come with basic pre-wiring for electrical or plumbing. While this can be a head start, always have it inspected by a professional to ensure it meets current codes and your specific needs.

- Ventilation Provisions: Look for a suitable roof opening or space where an exhaust hood and fan can be installed. Proper ventilation is a non-negotiable health code requirement.

- Legality and Documentation: Always verify the trailer has a clear title and VIN (Vehicle Identification Number). Ensure it can be legally registered in your state or province.

Where to Find Your Empty Food Truck Trailer

The search for the perfect empty food truck trailer can take you to various places, each with its own advantages:

- Online Marketplaces: Websites like eBay, Craigslist, Facebook Marketplace, and specialized trailer classifieds (e.g., trailersforless.com, truckpaper.com) are excellent starting points. They offer a wide range of options from private sellers and small dealerships.

- Trailer Manufacturers: Many companies specialize in building custom empty trailer shells, often referred to as "enclosed cargo trailers" or "concession trailer shells." This option allows you to specify dimensions, window placement, and even some basic framing.

- Auction Houses: Government surplus auctions, police auctions, and commercial equipment auctions can sometimes yield great deals on repossessed or decommissioned trailers. Be prepared to inspect thoroughly, as items are often sold "as-is."

- RV and Trailer Dealerships: Local dealerships often have new and used enclosed trailers that can be adapted for food truck use. They may also offer financing options.

- Food Truck Builders/Fabricators: Some food truck conversion companies also sell empty shells or may know where to find good candidates. They might even offer consultation services for the build-out.

- Word of Mouth & Local Classifieds: Don’t underestimate the power of local advertising or asking around within the mobile food community.

Budgeting and Beyond: The True Cost of an Empty Trailer

While the purchase price of an empty trailer is lower, it’s crucial to understand that it’s just the tip of the iceberg. Your budget must encompass the entire transformation from shell to culinary powerhouse.

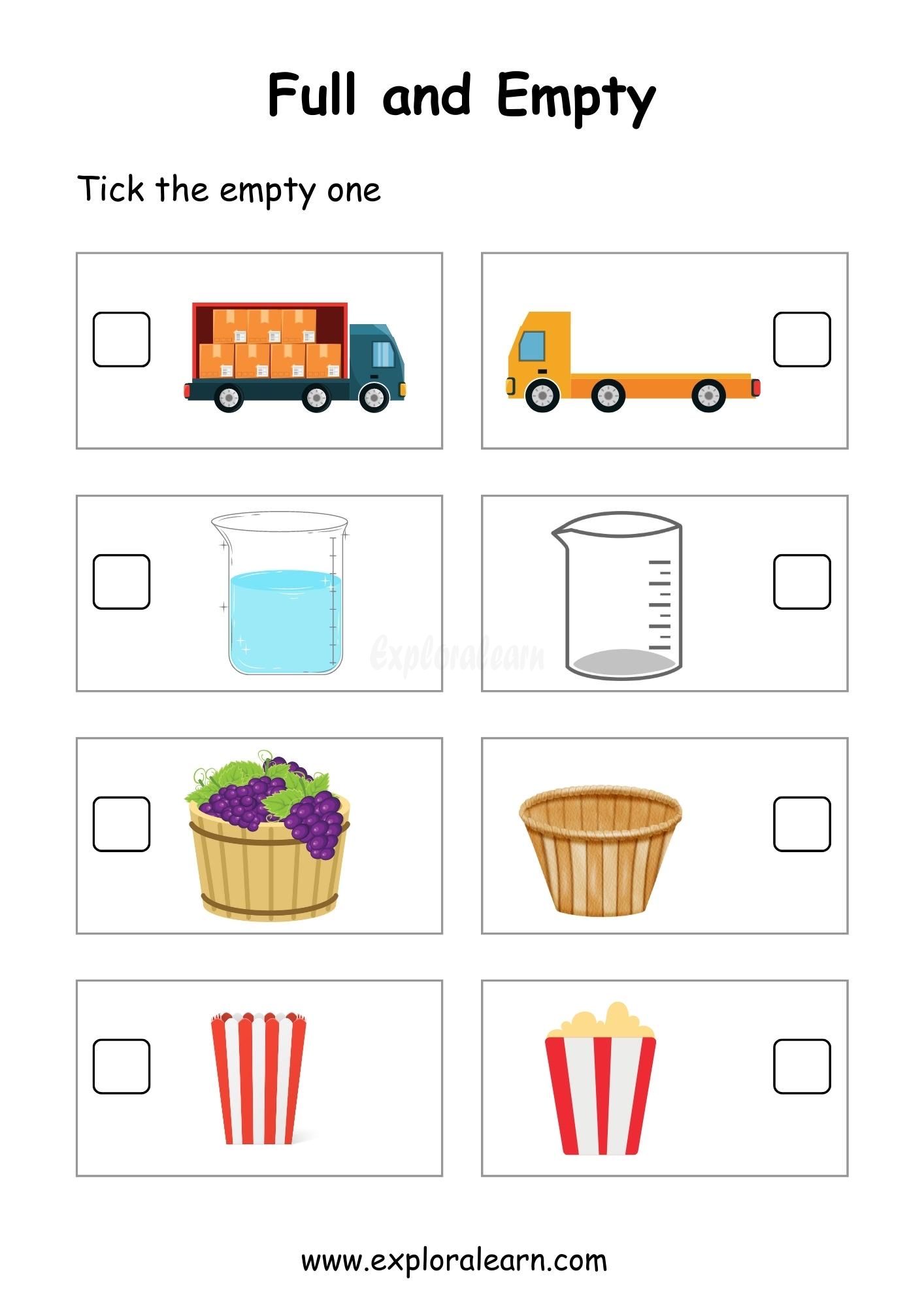

Estimated Purchase Price Range for Empty Food Truck Trailers (Shell Only):

| Size Category | Condition | Estimated Price Range (USD) | Key Features/Considerations |

|---|---|---|---|

| Small (8-12 ft) | Used/Basic | $3,000 – $8,000 | Often older, may require more repair. Good for single-person operations or specific, simple menus. Limited storage. |

| New/Premium Shell | $8,000 – $15,000 | Custom-built, new axles, clean interior. Ideal for precise layout, minimal initial repairs needed. | |

| Medium (14-20 ft) | Used/Basic | $7,000 – $15,000 | More versatile, can accommodate a wider range of equipment. Might need significant refurbishment. |

| New/Premium Shell | $15,000 – $30,000+ | Excellent starting point for most food truck concepts. Ample space for multiple stations and storage. | |

| Large (22+ ft) | Used/Basic | $12,000 – $25,000 | Suitable for high-volume operations, diverse menus, or large teams. Check frame integrity carefully due to potential age. |

| New/Premium Shell | $30,000 – $60,000+ | Top-tier option, often built to specific commercial standards. Provides maximum space and customization potential. |

Note: These prices are estimates and can vary significantly based on brand, location, specific features (e.g., ramp door, extra height), and market demand. Always factor in inspection, transport, and potential repair costs.

Beyond the Purchase Price – The "Hidden" Costs (Crucial for Budgeting):

- Transportation/Delivery: Getting the trailer to your location.

- Inspection Fees: Professional structural or mechanical inspection.

- Registration, Licensing, and Taxes: Varies by state/country.

- Insurance: Commercial auto insurance for the trailer, and general liability for your business.

- The Build-Out Costs (The Largest Portion):

- Kitchen Equipment: Grills, fryers, ovens, refrigerators, freezers, prep tables, sinks (3-compartment and handwashing). This can range from $10,000 to $50,000+.

- Electrical System: Wiring, outlets, breaker panel, generator/shore power hookup. ($2,000 – $8,000+)

- Plumbing System: Water tanks (fresh and grey), water heater, pump. ($1,500 – $5,000+)

- Ventilation System: Exhaust hood, fan, fire suppression system (mandatory for most cooking equipment). ($5,000 – $15,000+)

- Interior Finishing: Walls, flooring (non-slip, durable), shelving, lighting. ($2,000 – $10,000+)

- Exterior Branding: Paint, wrap, signage. ($1,000 – $7,000+)

- Permits and Inspections: Health department, fire department, electrical, plumbing. ($500 – $3,000+)

- Contingency Fund: Always budget an extra 15-20% for unexpected expenses.

The Customization Journey: Turning a Shell into a Culinary Hub

The build-out phase is where your vision comes to life. It’s a complex process that requires careful planning:

- Planning and Design: Before buying a single piece of equipment, create detailed floor plans. Consider your menu, workflow, equipment sizes, storage needs, and the number of staff. Utilize online tools or hire a designer if needed.

- Structural Modifications: This might involve cutting out serving windows, installing access doors, or reinforcing walls for heavy equipment.

- Insulation and Interior Walls: Install commercial-grade insulation and durable, easy-to-clean wall coverings (e.g., stainless steel, FRP panels) that meet health codes.

- Flooring: Choose non-slip, commercial-grade flooring that can withstand spills, heat, and heavy foot traffic.

- Utility Rough-Ins: Install all electrical wiring, plumbing lines for water and drainage, and gas lines (if using propane) before sealing walls.

- Equipment Installation: Mount your chosen kitchen equipment, ensuring proper clearances, ventilation connections, and utility hookups.

- Ventilation and Fire Suppression: Install your commercial exhaust hood, fan, and an automatic fire suppression system, which is mandatory for most cooking operations.

- Water System: Install fresh and grey water tanks, a water heater, pump, and three-compartment sink for washing, rinsing, and sanitizing, plus a separate handwashing sink.

- Finishing Touches: Add shelving, storage solutions, lighting, and any decorative elements.

- Exterior Branding: Apply your chosen paint, vinyl wrap, or signage to make your food truck stand out.

DIY vs. Professional Build-out: While DIY can save money, it requires significant skills in carpentry, electrical, plumbing, and welding, and a thorough understanding of health and fire codes. A professional fabricator ensures compliance, safety, and a higher quality finish, but at a higher cost. Many choose a hybrid approach, doing some tasks themselves and hiring professionals for critical systems (electrical, plumbing, fire suppression).

Challenges and Solutions

Building a food truck from an empty trailer isn’t without its hurdles, but most can be overcome with careful planning:

- Challenge: Unexpected Repairs/Hidden Damage in Used Trailers.

- Solution: Always get a professional third-party inspection before purchasing. Budget a contingency fund for unforeseen issues.

- Challenge: Navigating Complex Local Regulations (Health, Fire, Zoning).

- Solution: Research your local health department, fire marshal, and city planning office regulations early in the process. Consult with experienced food truck owners or a specialized consultant.

- Challenge: Overspending on the Build-out.

- Solution: Create a highly detailed budget for every single item. Prioritize essential equipment first. Get multiple quotes for services and equipment. Consider refurbished or gently used equipment where appropriate.

- Challenge: Insufficient Tow Vehicle Capability.

- Solution: Before buying a trailer, know its loaded weight (trailer + equipment + supplies) and ensure your tow vehicle’s towing capacity exceeds this weight by a comfortable margin.

- Challenge: DIY Build-out Takes Longer/Is More Complex Than Anticipated.

- Solution: Be realistic about your skills and time commitment. Don’t rush. Consult online resources, forums, and consider taking workshops. Don’t hesitate to call in professionals for tasks beyond your expertise.

Practical Advice and Actionable Insights

- Do Your Homework: Research market demand for your cuisine, potential locations, and competitors before committing to a trailer.

- Start with a Clear Business Plan: A detailed plan will guide your trailer design, equipment choices, and overall budget.

- Get it Inspected: Never buy a used trailer without a thorough professional inspection. This can save you thousands in hidden repairs.

- Negotiate: Don’t be afraid to negotiate the price, especially for used trailers.

- Network: Talk to other food truck owners. They are a wealth of information regarding trailer types, build-out challenges, and regulatory hurdles.

- Prioritize Safety and Compliance: Health and fire codes are non-negotiable. Building to code from the start saves time, money, and headaches later.

- Think Long-Term: Choose durable materials and equipment that can withstand the rigors of mobile operations.

Conclusion

The journey from an empty food truck trailer to a bustling mobile kitchen is an undertaking that requires vision, diligence, and a significant investment of time and resources. However, for the entrepreneurial spirit, it offers an unparalleled opportunity to build a business that is truly an extension of their culinary passion and business acumen. By starting with a blank canvas, you gain the freedom to craft a mobile workspace perfectly suited to your needs, ensuring efficiency, compliance, and a distinctive brand presence. While the path may present challenges, armed with comprehensive knowledge, meticulous planning, and a commitment to quality, that empty trailer can indeed become the foundation for your thriving mobile culinary dream.

Frequently Asked Questions (FAQ)

Q1: How much does an empty food truck trailer cost?

A1: The cost varies significantly based on size, condition (used vs. new shell), brand, and location. Generally, expect to pay anywhere from $3,000 for a basic used shell up to $60,000+ for a large, custom-built new shell. Please refer to the "Estimated Price Range for Empty Food Truck Trailers" table above for more details.

Q2: Can I build out an empty trailer myself, or do I need to hire professionals?

A2: You can build out an empty trailer yourself if you have strong DIY skills in carpentry, electrical, plumbing, and welding. However, for critical systems like electrical, plumbing, and especially the fire suppression system, it’s highly recommended to use licensed professionals to ensure safety and compliance with local health and fire codes. A hybrid approach (DIY for non-critical elements, pro for critical systems) is common.

Q3: What permits and licenses do I need for a food truck?

A3: This is highly dependent on your specific location (city, county, state/province). You will generally need: a business license, a health department permit (requiring a rigorous inspection of your mobile kitchen), fire department approval, potentially a mobile food vending permit, and vehicle registration/licensing. Research local regulations early in your planning process.

Q4: What’s the best size for an empty food truck trailer for a beginner?

A4: A medium-sized trailer (14-20 feet) is often ideal for beginners. It offers enough space for essential equipment, a comfortable working area for 1-2 people, and sufficient storage, without being overly difficult to tow or maneuver. Smaller trailers can be restrictive, while larger ones are more expensive to outfit and operate.

Q5: How long does it take to build out an empty food truck trailer?

A5: The timeline varies greatly depending on the complexity of your design, whether you’re doing it yourself or hiring professionals, and the availability of materials and equipment. A professional build-out can take 8-16 weeks, while a DIY project might stretch from 3-6 months or even longer, especially if you’re working part-time.

Q6: Do I need special insurance for a food truck trailer?

A6: Yes, you will need commercial insurance. This typically includes commercial auto insurance for the trailer itself (covering collision, liability, and often contents), general liability insurance for your business operations, and potentially workers’ compensation if you have employees. Consult with an insurance broker specializing in commercial vehicles and small businesses.