Front Part Of Pick Up Truck That Connects Wheels

Front Part Of Pick Up Truck That Connects Wheels cars.truckstrend.com

The humble pickup truck, a workhorse revered for its utility, towing capacity, and off-road prowess, owes much of its capability to a sophisticated, yet often overlooked, assembly of components: the Front Part Of Pick Up Truck That Connects Wheels. Far more than just a simple linkage, this intricate system is the very foundation of a truck’s steering precision, ride comfort, handling stability, and overall safety. It’s the unsung hero that translates driver input into directional changes, absorbs road imperfections, and ensures the front wheels maintain optimal contact with the ground, whether you’re cruising on the highway, navigating a construction site, or conquering a rugged trail.

In essence, the "Front Part Of Pick Up Truck That Connects Wheels" encompasses the entire front suspension, steering, and (for four-wheel-drive models) the front drive axle assembly. Understanding this critical area is paramount for any truck owner, from daily drivers to serious off-road enthusiasts, as its health directly impacts everything from tire wear to emergency braking performance. This comprehensive guide will delve into the anatomy, function, maintenance, and considerations for this vital section of your pickup.

Front Part Of Pick Up Truck That Connects Wheels

Anatomy of the "Front Part Of Pick Up Truck That Connects Wheels"

To truly appreciate the complexity and importance of the front end, let’s break down its primary components:

1. Suspension System Components

The suspension system is designed to absorb shocks, maintain tire contact, and support the vehicle’s weight.

- Control Arms (A-Arms/Wishbones): These are hinged components that connect the steering knuckle (where the wheel attaches) to the vehicle’s frame. They allow vertical wheel movement while controlling lateral and longitudinal motion. Most independent front suspension (IFS) systems use upper and lower control arms.

- Ball Joints: Acting like flexible pivots, ball joints connect the control arms to the steering knuckle. They allow the steering knuckle to pivot and the wheel to move up and down, enabling steering and suspension articulation.

- Springs (Coil, Leaf, Torsion Bars):

- Coil Springs: Helical springs that compress to absorb shocks. Often used in conjunction with shock absorbers in a coil-over setup, common in modern IFS pickups.

- Leaf Springs: Layers of metal leaves bolted together, commonly found on the rear axles of pickups, but historically used on front solid axles for heavy-duty applications.

- Torsion Bars: Long, straight metal bars that twist to absorb road shocks. One end is anchored to the frame, the other to a control arm. Often found in older or some current heavy-duty IFS designs.

- Shock Absorbers (Dampers): These hydraulic or gas-filled cylinders dampen the oscillations of the springs, preventing excessive bouncing and maintaining tire contact with the road. Without them, the truck would continue to bounce long after hitting a bump.

- Steering Knuckles (Spindles): The component that houses the wheel hub and bearing, and where the wheel is mounted. It connects to the control arms via ball joints and the tie rods for steering.

- Sway Bar (Anti-Roll Bar/Stabilizer Bar): A U-shaped metal bar that connects the left and right sides of the suspension. It resists body roll during cornering, keeping the truck flatter and improving handling stability.

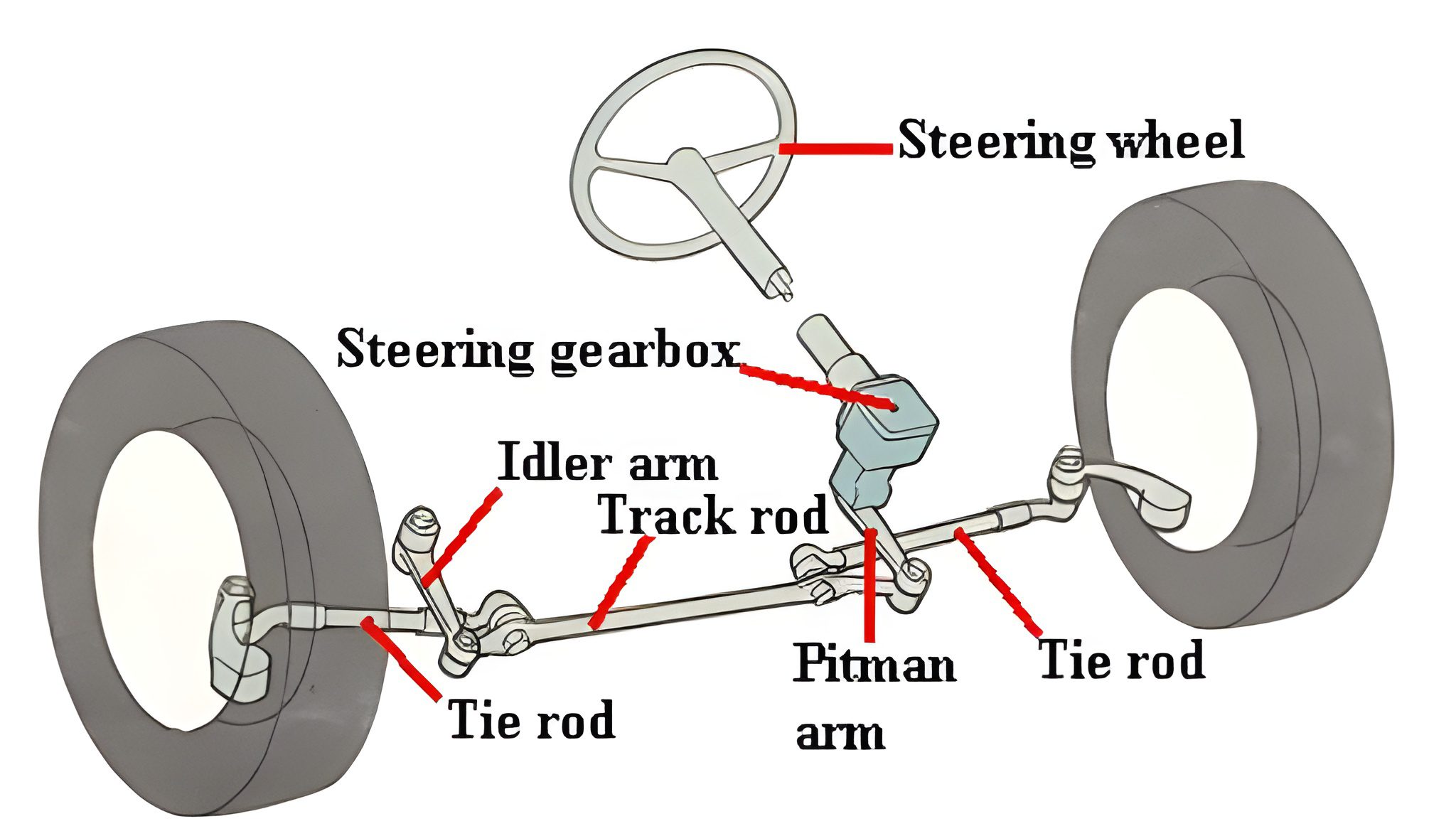

2. Steering System Components

The steering system allows the driver to control the direction of the front wheels.

- Steering Rack and Pinion: Prevalent in modern light-duty pickups with IFS. A pinion gear (on the steering shaft) meshes with a linear rack gear, converting rotational steering wheel movement into lateral motion to turn the wheels.

- Recirculating Ball Steering: More common in older or heavy-duty trucks with solid front axles. A gearbox translates steering input into movement of a pitman arm, which then connects to a series of linkages (drag link, tie rods) to steer the wheels.

- Tie Rods (Inner and Outer): Connect the steering rack/linkage to the steering knuckles, directly transmitting steering input to the wheels.

3. Drive System Components (for 4WD Pickups)

In four-wheel-drive trucks, the front part also includes the components that deliver power to the front wheels.

- Front Axle Assembly: Contains the differential (which allows wheels to spin at different speeds during turns) and axle shafts that transmit power from the differential to the wheels.

- CV Joints (Constant Velocity Joints): Used in IFS 4WD systems, these joints allow power transmission through varying angles as the wheels move up and down with the suspension.

- Wheel Hubs and Bearings: The assembly that the wheel mounts to, allowing it to spin freely while supporting the vehicle’s weight.

The Critical Role of the "Front Part Of Pick Up Truck That Connects Wheels"

This complex assembly performs several vital functions:

- Precision Steering & Control: It’s the primary mechanism for directional control, enabling the driver to maneuver the vehicle safely and precisely. Worn components here can lead to vague steering, excessive play, and difficulty maintaining a straight line.

- Ride Comfort & Stability: The suspension components absorb road imperfections, providing a smooth ride. They also keep the tires firmly planted on the road, crucial for braking and cornering stability, especially under varying load conditions.

- Load Carrying & Towing Capability: For pickups, the front end must be robust enough to handle the weight of heavy engines, front-mounted accessories (like winches or snow plows), and the dynamic forces of towing. Stronger springs and heavy-duty components are often designed for this purpose.

- Safety: A well-maintained front end is critical for safety. It ensures effective braking, stable emergency maneuvers, and predictable handling, directly reducing the risk of accidents.

- Off-Road Performance: For off-road pickups, the design of the front suspension dictates articulation (how much the wheels can move independently to maintain traction over uneven terrain) and ground clearance.

Common Types and Configurations

The "Front Part Of Pick Up Truck That Connects Wheels" can be broadly categorized by its suspension design:

- Independent Front Suspension (IFS):

- Description: Each front wheel moves up and down independently of the other. Most modern light-duty and some heavy-duty pickups use IFS.

- Pros: Superior ride comfort, better on-road handling, reduced unsprung weight, and more precise steering.

- Cons: Less articulation for extreme off-roading compared to solid axles, potentially more complex and expensive to repair or lift significantly.

- Examples: Ford F-150, Ram 1500, Chevrolet Silverado 1500, Toyota Tacoma.

- Solid Front Axle (Live Axle):

- Description: The two front wheels are rigidly connected by a single axle housing. When one wheel goes over a bump, the other wheel is directly affected. Common in heavy-duty pickups (e.g., Ford F-250/350, Ram 2500/3500) and older trucks, and some dedicated off-road vehicles.

- Pros: Extremely durable, excellent articulation for serious off-roading, simpler design, and often easier to lift significantly.

- Cons: Harsher ride quality, increased unsprung weight (leading to less precise handling on pavement), and greater body roll.

Maintenance and Care for the "Front Part Of Pick Up Truck That Connects Wheels"

Proactive maintenance is key to the longevity and performance of your truck’s front end.

- Regular Inspections: Periodically visually inspect all components. Look for:

- Leaking shocks: A greasy residue indicates a failed seal.

- Cracked or torn rubber boots: On ball joints, tie rod ends, and CV joints. These protect the internal components from dirt and moisture.

- Excessive play: Try to wiggle components by hand (when the truck is safely jacked up) or have a mechanic check for looseness.

- Bent or damaged components: After hitting potholes or off-road excursions.

- Wheel Alignment: Crucial for tire wear and steering precision. Get an alignment check whenever you replace front suspension or steering components, hit a significant pothole, or notice uneven tire wear or steering pull.

- Tire Rotation and Balancing: While not directly part of the "Front Part Of Pick Up Truck That Connects Wheels," proper tire maintenance ensures optimal performance and can highlight underlying issues with the front end.

- Lubrication: Some older or heavy-duty components have grease fittings (zerk fittings) that require regular lubrication with a grease gun.

- Recognize Warning Signs:

- Unusual noises: Clunking, rattling, squeaking over bumps.

- Vibrations: Through the steering wheel or floorboards.

- Loose or wandering steering: Difficulty keeping the truck straight.

- Uneven tire wear: Scalloping, feathering, or excessive wear on one side of the tire.

- Steering wheel not centered: After driving straight.

- Excessive nose dive or squat: During braking or acceleration.

Upgrades and Modifications

Many truck owners choose to modify the "Front Part Of Pick Up Truck That Connects Wheels" for improved performance or aesthetics:

- Lift Kits: Raise the truck’s ride height, often involving new control arms, taller springs/shocks, or spacers. Crucially, a proper alignment is mandatory after any lift.

- Performance Shocks: Designed for better damping characteristics, especially beneficial for off-roading or towing.

- Heavy-Duty Components: Upgraded control arms, tie rods, and ball joints made from stronger materials can improve durability for severe use.

- Steering Stabilizers: Reduce steering wander and bump steer, particularly useful for lifted trucks or those with larger tires.

- Sway Bar End Links: Upgraded links can improve sway bar effectiveness and durability.

Practical Advice and Actionable Insights

- Don’t Ignore Warning Signs: Noises, vibrations, or changes in handling are your truck’s way of telling you something is wrong. Address them promptly to prevent further damage or safety hazards.

- Prioritize Professional Inspection: While visual checks are good, a qualified mechanic can perform a thorough inspection, identifying subtle wear and tear before it becomes a major problem.

- Understand Your Truck’s Specific Setup: Know whether your truck has IFS or a solid axle, and what type of springs it uses. This knowledge helps in diagnosing issues and selecting appropriate replacement parts or upgrades.

- Invest in Quality Replacement Parts: When components need replacement, opt for reputable brands. Cheaper parts may save money initially but often have shorter lifespans and can compromise performance and safety.

Concluding Summary

The Front Part Of Pick Up Truck That Connects Wheels is a sophisticated and highly engineered system that is fundamental to your pickup truck’s performance, safety, and utility. From the intricate movements of its suspension components to the precision of its steering linkage and the power delivery of its front axle, every part plays a crucial role. By understanding its components, recognizing signs of wear, and committing to regular maintenance, you ensure your pickup remains reliable, safe, and capable of tackling whatever challenges you throw its way. Proactive care for this vital assembly isn’t just about prolonging the life of your truck; it’s about safeguarding your investment and, more importantly, your safety on the road or trail.

Price Table: Representative Components of the "Front Part Of Pick Up Truck That Connects Wheels"

Please note: Prices are highly variable based on truck make/model/year, part quality (OEM vs. aftermarket), labor rates, and geographic location. These are estimated ranges for parts and typical labor for replacement.

| Component Category | Typical Components Included | Estimated Part Cost (Each) | Estimated Labor Cost (Each Component/Pair) | Notes |

|---|---|---|---|---|

| Suspension | Upper Control Arm (w/ ball joint) | $80 – $300 | $150 – $350 | Often replaced as an assembly. |

| Lower Control Arm (w/ ball joint) | $100 – $400 | $180 – $400 | Can be more complex due to spring/shock mounting. | |

| Ball Joint (Upper or Lower, if separable) | $30 – $100 | $100 – $250 | Requires pressing in/out for some designs. | |

| Shock Absorber (Front) | $50 – $250 | $80 – $200 | Often recommended to replace in pairs. | |

| Coil Spring (Front) | $70 – $200 | Included with shock replacement if coil-over. | Can be part of a strut assembly. | |

| Strut Assembly (Coil Spring + Shock) | $120 – $400 | $150 – $350 | Common for IFS; often easier to replace as a complete unit. | |

| Torsion Bar | $100 – $250 | $200 – $400 | Less common on new trucks. | |

| Sway Bar End Link | $20 – $80 | $50 – $120 | Often replaced in pairs. | |

| Steering | Tie Rod End (Inner or Outer) | $30 – $150 | $80 – $200 | Requires alignment after replacement. |

| Steering Rack & Pinion Assembly | $400 – $1200 | $400 – $800 | Major component, usually includes tie rod ends. | |

| Steering Gear Box (Recirculating Ball) | $300 – $1000 | $350 – $700 | Common for solid axle trucks. | |

| Drive (4WD) | CV Axle Shaft Assembly (Front) | $100 – $350 | $200 – $450 | For IFS 4WD only. |

| Wheel Hub Assembly (w/ bearing) | $80 – $300 | $150 – $400 | Often includes ABS sensor. | |

| Alignment | 2-Wheel Alignment (Front) | N/A | $80 – $150 | Essential after suspension/steering work; highly recommended annually. |

| Total Front End Rebuild (Parts Only) | Comprehensive kit (e.g., all control arms, ball joints, tie rods, shocks) | $800 – $3000+ | Varies wildly (multiple components) | Often more cost-effective to buy kits for major overhauls. |

Note: "Estimated Labor Cost" is for typical shop rates and does not include shop fees, taxes, or diagnostic time.

Frequently Asked Questions (FAQ) about the "Front Part Of Pick Up Truck That Connects Wheels"

Q1: What are the common signs that my truck’s front end needs attention?

A1: Look out for unusual noises (clunking, squeaking, rattling) over bumps, vibrations in the steering wheel or floorboards, loose or wandering steering, uneven tire wear, a vehicle that pulls to one side, or excessive bounce after hitting a bump.

Q2: How often should I get a front-end alignment?

A2: It’s recommended to get an alignment check at least once a year, or whenever you notice steering or tire wear issues. It’s absolutely crucial after replacing any front suspension or steering components (e.g., tie rods, control arms, shocks) or after hitting a major pothole or curb.

Q3: Can I replace "Front Part Of Pick Up Truck That Connects Wheels" components myself?

A3: Some components, like shocks or sway bar end links, can be replaced by a DIYer with mechanical aptitude and proper tools. However, complex jobs involving ball joints, control arms, steering racks, or anything requiring specialized presses or alignment after installation are best left to professional mechanics. Safety is paramount when working under a vehicle.

Q4: What’s the main difference between Independent Front Suspension (IFS) and a Solid Front Axle?

A4: With IFS, each front wheel moves independently, offering a smoother ride and better on-road handling. A solid front axle connects both front wheels rigidly, making it extremely durable and excellent for off-road articulation, but typically at the expense of ride comfort on pavement.

Q5: Why is the condition of the "Front Part Of Pick Up Truck That Connects Wheels" so important for towing?

A5: When towing, the truck’s front end is subjected to increased weight transfer and dynamic forces. Worn components can lead to unstable handling, excessive sway, reduced steering control, and increased braking distances, all of which compromise safety and performance, especially with heavy loads. A robust and well-maintained front end ensures stability and control.