Ft Box Truck Reefer Dimension: A Comprehensive Guide to Cold Chain Efficiency

Ft Box Truck Reefer Dimension: A Comprehensive Guide to Cold Chain Efficiency cars.truckstrend.com

In the intricate world of logistics, where every degree matters and every inch counts, the "Ft Box Truck Reefer Dimension" stands as a critical parameter. Far more than just a measurement, it represents the heart of cold chain transportation – the capacity and capability of a refrigerated box truck to safely and efficiently move perishable goods. From farm-fresh produce and delicate pharmaceuticals to vibrant flowers and temperature-sensitive chemicals, understanding these dimensions is paramount for businesses aiming to optimize their operations, ensure product integrity, and maintain profitability. This comprehensive guide will delve into the nuances of Ft Box Truck Reefer Dimensions, offering insights for anyone involved in the cold chain, from fleet managers to small business owners.

Understanding the Core Components of Reefer Dimensions

Ft Box Truck Reefer Dimension: A Comprehensive Guide to Cold Chain Efficiency

When we talk about "Ft Box Truck Reefer Dimension," we’re primarily referring to the usable cargo space within the refrigerated compartment, often expressed by its nominal length in feet. However, a complete understanding requires looking at several interconnected measurements:

- Exterior Dimensions: These encompass the entire truck, including the cab and the refrigeration unit mounted on the front. They include the overall Length, Width, and Height. Exterior dimensions are crucial for route planning, navigating tight city streets, and ensuring compatibility with loading docks and overhead clearances.

- Interior Dimensions (Cargo Area): This is the most critical aspect for payload capacity. It details the Usable Length, Width, and Height of the refrigerated box. The "Ft" in "Ft Box Truck Reefer Dimension" most commonly refers to this interior length. It dictates how many pallets, crates, or packages can fit inside, influencing payload optimization.

- Door Opening Dimensions: The Height and Width of the rear and/or side doors are vital for efficient loading and unloading. A reefer truck might have ample interior space, but if the door opening is too small for a standard pallet jack or forklift, it can lead to significant operational bottlenecks.

- Refrigeration Unit Intrusion: The refrigeration unit, typically mounted on the front wall of the box, intrudes into the interior cargo space. This intrusion reduces the effective interior length, a factor often overlooked but crucial for maximizing usable volume.

- Wall Thickness: Reefer trucks require robust insulation to maintain precise temperatures. This insulation adds significant thickness to the walls, floor, and ceiling, reducing the interior dimensions compared to a standard dry box truck of the same exterior size. Typically, insulation can reduce interior width and height by 6-10 inches and interior length by 4-6 inches due to the reefer unit.

Common Ft Box Truck Reefer Dimension Categories

Reefer box trucks come in a range of sizes, categorized by their nominal cargo box length, designed to meet diverse logistical needs:

- Small (e.g., 10-14 ft): These compact reefers are ideal for last-mile delivery, catering services, small-scale local distribution, and urban environments where maneuverability is key.

- Typical Interior: Length 9-13 ft, Width 6-7 ft, Height 6-7 ft.

- Payload: Suitable for 2-4 standard pallets.

- Medium (e.g., 16-20 ft): The workhorses of regional distribution, these trucks are commonly used by food service distributors, local produce suppliers, and floral companies. They offer a good balance of capacity and maneuverability.

- Typical Interior: Length 15-19 ft, Width 7.5-8 ft, Height 7.5-8 ft.

- Payload: Suitable for 6-8 standard pallets.

.png/:/rs=w:600,h:300,cg:true,m/cr=w:600,h:300)

- Large (e.g., 22-26 ft): Approaching the capacity of smaller reefer trailers, these larger box trucks are employed for supermarket supply, longer regional routes, and high-volume distribution. While less common for long-haul than semi-trailers, they offer significant capacity without requiring a Class A CDL (depending on Gross Vehicle Weight Rating – GVWR).

- Typical Interior: Length 21-25 ft, Width 8-8.5 ft, Height 8-8.5 ft.

- Payload: Suitable for 10-12 standard pallets.

It’s vital to remember that "Ft" in the context of "Ft Box Truck Reefer Dimension" refers to the nominal length of the cargo box. Actual interior dimensions will always be slightly less due to insulation and the refrigeration unit.

Why Accurate Dimensions Matter

Understanding and accurately assessing Ft Box Truck Reefer Dimensions is not merely an academic exercise; it has profound practical implications for a business’s efficiency, compliance, and bottom line:

- Payload Optimization: Knowing the precise interior dimensions allows for maximizing the amount of product transported per trip. This directly translates to fewer trips, reduced fuel consumption, and lower labor costs, significantly impacting operational efficiency and profitability.

- Temperature Control Efficiency: An appropriately sized reefer unit for the cargo volume ensures efficient temperature maintenance. An undersized unit will struggle and overwork, leading to higher fuel consumption and potential breakdowns. An oversized unit might also be less efficient in smaller loads.

- Route Planning & Accessibility: Exterior dimensions directly impact a truck’s ability to navigate specific routes, enter urban areas, and fit into loading docks. Miscalculating these can lead to costly delays, detours, or even damage.

- Regulatory Compliance: Understanding the truck’s GVWR (Gross Vehicle Weight Rating) in conjunction with its dimensions helps ensure compliance with weight limits and bridge clearances, preventing fines and safety hazards.

- Cost Implications: The purchase or lease cost of a reefer truck is heavily influenced by its size. Moreover, larger trucks generally consume more fuel. Accurate dimension assessment helps in making a cost-effective acquisition decision aligned with actual needs.

- Product Integrity: Properly fitting cargo within the reefer prevents shifting and damage during transit. It also ensures consistent airflow around all products, crucial for maintaining uniform temperature and preventing spoilage.

Factors Influencing Ft Box Truck Reefer Dimensions

Several factors contribute to the final dimensions of a reefer box truck, making it crucial to verify specifications for each model:

- Chassis Size and Manufacturer: The underlying truck chassis (e.g., Ford, Isuzu, Hino, Freightliner) dictates the foundation upon which the reefer box is built, influencing overall length and weight capacity.

- Body Manufacturer: Different body builders (e.g., Morgan, Supreme, Kidron, Utilimaster) use varying designs, construction materials, and insulation techniques, leading to slight variations in interior and exterior dimensions for the same nominal length.

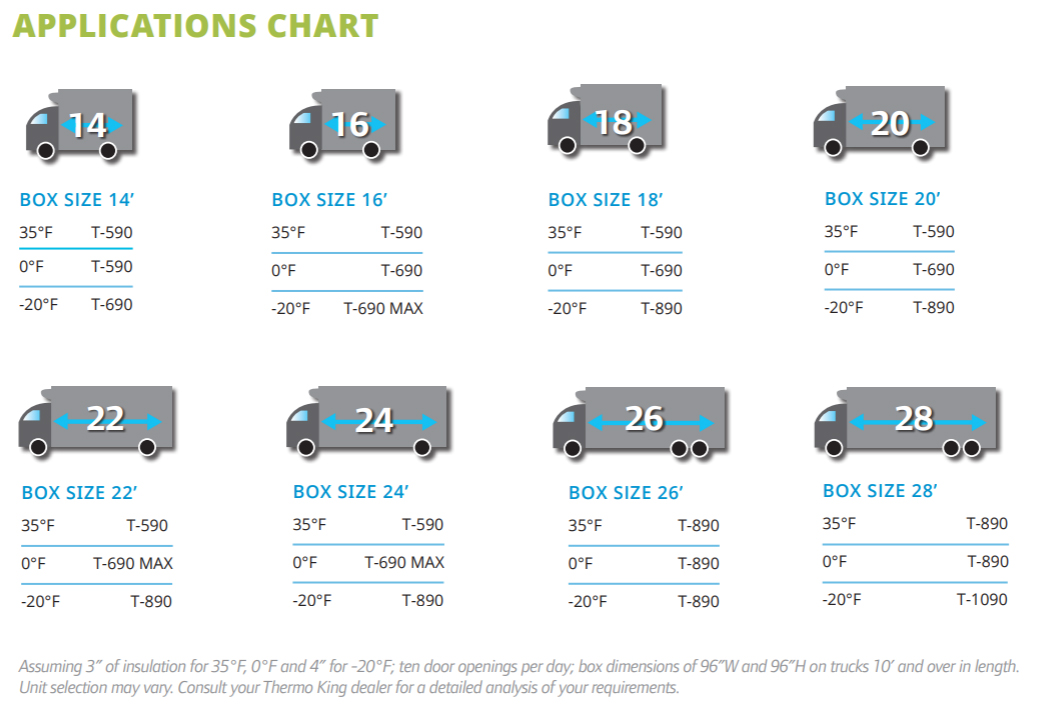

- Refrigeration Unit Type and Placement: The size and type of the refrigeration unit (e.g., Carrier Transicold, Thermo King) – whether nose-mounted or skirt-mounted – significantly impact the interior usable length and overall vehicle weight.

- Insulation Thickness and R-Value: The level of insulation required (driven by the desired temperature range) directly affects wall, floor, and ceiling thickness, thus reducing interior space. Higher R-values (better insulation) often mean thicker walls.

- Customization and Accessories: Internal features like E-track systems, shelving, bulkheads, and liftgates can further impact usable interior dimensions and payload capacity.

Practical Advice for Selecting the Right Reefer Dimension

Choosing the optimal Ft Box Truck Reefer Dimension is a strategic decision that requires careful consideration:

- Analyze Your Cargo Profile:

- Volume: How many cubic feet of product do you typically transport?

- Weight: What is the average weight of your typical load? Ensure the truck’s payload capacity (GVWR minus curb weight) can handle it.

- Packaging: What are the dimensions of your boxes, crates, or pallets? Will they fit efficiently without wasted space?

- Temperature Requirements: What are the precise temperature ranges needed for your products (e.g., frozen, refrigerated, cool)? This dictates insulation needs.

- Consider Your Routes and Delivery Points:

- Urban vs. Highway: Smaller trucks are better for congested urban areas. Larger trucks are more efficient for longer highway runs.

- Loading Dock Access: Verify exterior dimensions and door heights against typical loading dock specifications.

- Maneuverability: How tight are the turns and parking spaces at your typical delivery locations?

- Plan for Future Growth: Don’t just buy for today’s needs. Consider your projected growth in volume or expansion into new markets. It’s often more cost-effective to buy slightly larger than immediately necessary than to outgrow a truck quickly.

- Balance Cost vs. Capacity: Larger trucks are more expensive to purchase, operate (fuel, maintenance), and insure. Find the sweet spot where capacity meets your needs without excessive overhead.

- Consult with Experts: Work closely with reputable truck dealers and body builders. They can provide detailed specifications, help you configure the right insulation and refrigeration unit, and offer insights based on your specific business model.

Challenges and Solutions Related to Reefer Dimensions

Operating with reefer dimensions presents unique challenges, but effective solutions exist:

- Challenge: Limited Interior Space Due to Insulation.

- Solution: Optimize product packaging for cubic efficiency. Explore advanced, thinner insulation materials with higher R-values if available within budget. Implement smart loading strategies, such as cross-stacking or utilizing every available vertical inch.

- Challenge: Maneuverability of Larger Trucks in Urban Settings.

- Solution: Invest in driver training focused on navigating tight spaces. Utilize route optimization software that considers vehicle dimensions. For dense urban delivery, consider a fleet mix that includes smaller, more agile reefer trucks.

- Challenge: Inconsistent Dimensions Across Manufacturers.

- Solution: Always request and meticulously review detailed specification sheets or blueprints for any truck you are considering. Do not rely solely on nominal "Ft" measurements. Conduct physical measurements if possible before purchase or lease.

- Challenge: High Operating Costs (Fuel, Maintenance) for Reefer Units.

- Solution: Choose the most fuel-efficient refrigeration unit for your needs. Implement preventative maintenance schedules for the reefer unit to ensure optimal performance and avoid costly breakdowns. Consider telematics systems to monitor temperature, fuel consumption, and driver behavior.

Estimated Ft Box Truck Reefer Dimensions & Price Range

Please note that prices are highly variable based on chassis manufacturer, body builder, refrigeration unit, features, condition (new vs. used), mileage, and market demand. These are general estimates for reference.

| Nominal Box Length (ft) | Approx. Exterior Length (ft) | Approx. Interior Length (ft) | Interior Width (ft) | Interior Height (ft) | Approx. New Unit Price Range (USD) | Approx. Used Unit Price Range (USD) |

|---|---|---|---|---|---|---|

| 10 ft | 18-20 | 9-9.5 | 6.5-7 | 6.5-7 | $60,000 – $90,000 | $25,000 – $50,000 |

| 14 ft | 22-24 | 13-13.5 | 7-7.5 | 7-7.5 | $75,000 – $110,000 | $35,000 – $65,000 |

| 18 ft | 26-28 | 17-17.5 | 7.5-8 | 7.5-8 | $90,000 – $130,000 | $45,000 – $80,000 |

| 22 ft | 30-32 | 21-21.5 | 8-8.2 | 8-8.2 | $105,000 – $150,000 | $55,000 – $95,000 |

| 26 ft | 34-36 | 25-25.5 | 8-8.3 | 8-8.3 | $120,000 – $170,000+ | $65,000 – $110,000+ |

Note: Interior dimensions are estimates, accounting for insulation and reefer unit intrusion. Always verify exact specifications with the manufacturer or dealer.

Frequently Asked Questions (FAQ)

Q1: What does "Ft" in reefer dimensions specifically refer to?

A1: "Ft" typically refers to the nominal interior length of the cargo box, measured in feet. However, it’s crucial to remember that the usable interior length will be slightly less due to insulation thickness and the space taken by the refrigeration unit on the front wall.

Q2: How much interior space do I lose due to insulation in a reefer truck compared to a dry box truck?

A2: You can expect to lose approximately 6-10 inches from both the interior width and height, and about 4-6 inches from the interior length (due to the reefer unit’s presence on the front wall). This varies based on insulation type and thickness.

Q3: Are reefer dimensions standardized across all manufacturers?

A3: No, while general categories (e.g., 14ft, 20ft) exist, exact interior and exterior dimensions can vary significantly between different chassis manufacturers and body builders. Always consult specific vehicle specifications.

Q4: Can I rent a reefer box truck to test different dimensions?

A4: Yes, many commercial truck rental companies (e.g., Ryder, Penske, U-Haul Truck Rental) offer refrigerated box trucks for short-term or long-term rental, allowing businesses to test various sizes before committing to a purchase or lease.

Q5: What’s the main difference between a reefer box truck and a reefer trailer regarding dimensions?

A5: A reefer box truck is a single, self-contained unit (cab and cargo box are one vehicle), typically ranging from 10 to 26 feet in box length. A reefer trailer is a separate unit pulled by a semi-tractor, generally much larger (e.g., 48 to 53 feet long), designed for long-haul, high-volume transportation. Box trucks are favored for local distribution and urban maneuverability.

Q6: How do I accurately measure a reefer truck’s interior dimensions?

A6: Use a long tape measure. For length, measure from the inside of the rear door to the inside of the front wall (be aware of the reefer unit intrusion). For width, measure wall-to-wall at multiple points to account for any slight tapering. For height, measure from the floor to the ceiling, again at various points.

Concluding Summary

The "Ft Box Truck Reefer Dimension" is more than just a number; it’s a foundational element in effective cold chain management. A thorough understanding of interior and exterior measurements, coupled with an awareness of the factors that influence them, empowers businesses to make informed decisions that directly impact their operational efficiency, cost-effectiveness, and ability to deliver perishable goods in pristine condition. By carefully assessing cargo needs, route complexities, and future growth potential, companies can select the right-sized reefer truck, ensuring optimal payload, efficient temperature control, and ultimately, a robust and reliable cold chain. In a market where precision is paramount, mastering the dimensions of your refrigerated fleet is a strategic imperative.