Internal Dims Ft Straight Truck: Your Ultimate Guide to Maximizing Cargo Space

Internal Dims Ft Straight Truck: Your Ultimate Guide to Maximizing Cargo Space cars.truckstrend.com

In the world of logistics, moving, and freight, understanding the precise dimensions of your vehicle is not just helpful—it’s absolutely critical. When we talk about "Internal Dims Ft Straight Truck," we’re diving into the core measurements that dictate how much cargo you can actually fit inside a straight truck’s cargo area, expressed in feet. A straight truck, also known as a box truck, cube truck, or moving truck, is a single-unit vehicle where the cab and the cargo body are permanently attached to the same chassis. Unlike tractor-trailers, they don’t separate, making their internal dimensions a direct indicator of their usable volume.

The internal dimensions—length, width, and height of the cargo box—are the unsung heroes of efficient transport. Misjudging these can lead to costly delays, damaged goods, wasted fuel from multiple trips, or even legal complications due to overloading or improper load securement. Whether you’re a business owner planning deliveries, a logistics manager optimizing routes, or an individual planning a move, mastering the nuances of a straight truck’s internal dimensions is paramount for success. This comprehensive guide will explore every facet of internal dimensions, providing practical insights to help you make informed decisions and maximize your operational efficiency.

Internal Dims Ft Straight Truck: Your Ultimate Guide to Maximizing Cargo Space

Understanding the Basics: What Are Internal Dimensions?

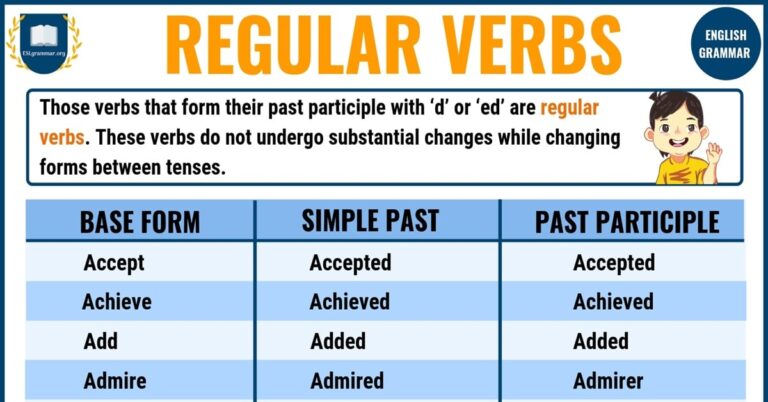

At its simplest, the internal dimensions of a straight truck refer to the usable space within its cargo compartment. These are typically measured as:

- Internal Length (L): The distance from the inside of the rear door to the inside of the front wall of the cargo box. This is the maximum length of an item that can lay flat on the floor.

- Internal Width (W): The distance between the inside of the left wall and the inside of the right wall of the cargo box. This is crucial for determining how many items can be placed side-by-side.

- Internal Height (H): The distance from the floor of the cargo box to the lowest point of the ceiling. This is vital for stacking items and accommodating tall cargo.

These measurements are typically provided in feet and inches. It’s crucial to distinguish internal dimensions from external dimensions, which refer to the truck’s overall size (bumper to bumper, mirror to mirror, ground to roof). While external dimensions are important for maneuverability, bridge clearances, and parking, it’s the internal dimensions that directly impact your payload capacity.

Why Internal Dimensions Matter: Importance in Logistics and Operations

The meticulous consideration of internal dimensions profoundly impacts several critical aspects of logistics and operations:

- Capacity Planning and Maximization: The most obvious benefit. Knowing the exact internal cubic footage (L x W x H) allows you to calculate precisely how much cargo can fit, helping you avoid under-utilization (paying for unused space) or over-utilization (requiring multiple trips).

- Cargo Compatibility: Certain goods, like large appliances, furniture, industrial equipment, or standard pallets, have specific dimensions. Accurate internal measurements ensure that your cargo will physically fit through the door opening and then comfortably within the cargo area without needing to be forced or damaged.

- Cost Efficiency: Right-sizing your truck to your cargo volume prevents wasted fuel and driver hours. Using a truck that’s too large is inefficient, while using one that’s too small necessitates additional trips, doubling costs and time.

- Safety and Compliance: Understanding dimensions helps in proper weight distribution and preventing overloading. Overloaded trucks are unsafe, difficult to control, and can lead to hefty fines. Knowing the height helps avoid clearance issues under bridges or in tunnels.

- Loading and Unloading Efficiency: Proper internal dimensions ensure there’s enough space for personnel or equipment (like forklifts) to maneuver inside the truck, facilitating faster and safer loading/unloading processes.

- Strategic Route Planning: While external dimensions are primary for route planning, understanding internal height helps confirm that specialized equipment or tall cargo will fit under specific overhead obstructions along the route.

Common Straight Truck Sizes and Their Internal Dimensions

Straight trucks come in various sizes, each suited for different cargo volumes and weights. Here are common examples with their typical internal dimensions:

- 10-12 ft Box Trucks (Small): Ideal for small moves (studio/1-bedroom apartment) or local deliveries.

- Internal Dims: ~9’10" – 11’6" L x 6′ – 6’6" W x 6′ – 6’6" H

- Cubic Feet: 350-500 cu ft

- 15-17 ft Box Trucks (Medium): Good for 1-2 bedroom apartments or medium-sized commercial deliveries.

- Internal Dims: ~14’6" – 16′ L x 7′ – 7’6" W x 7′ – 7’6" H

- Cubic Feet: 700-900 cu ft

- 20-22 ft Box Trucks (Large): Suitable for 2-3 bedroom homes or larger commercial freight.

- Internal Dims: ~19′ – 21′ L x 7’6" – 8′ W x 7’6" – 8′ H

- Cubic Feet: 1,200-1,400 cu ft

- 24-26 ft Box Trucks (Extra-Large/Heavy Duty): Best for 3-4+ bedroom homes, significant commercial freight, or specialized equipment.

- Internal Dims: ~23′ – 25′ L x 8′ W x 8′ – 8’6" H

- Cubic Feet: 1,400-1,700 cu ft

Note: These are approximations. Actual dimensions vary significantly by manufacturer, model year, and specific features.

Factors Influencing Usable Internal Dimensions

While standard internal dimensions provide a baseline, several design elements can impact the actual usable space:

- Wheel Wells: These protrusions into the cargo area, especially in smaller and medium-sized trucks, significantly reduce floor width at certain points. This is crucial when loading wide items or standard pallets.

- Door Opening Dimensions: The rear door opening (width and height) is often slightly smaller than the internal dimensions of the box itself due to the door frame, hinges, and liftgate mechanisms. Always verify this clearance for large or awkwardly shaped items.

- Refrigeration/Insulation Units: For refrigerated (reefer) trucks, the thick insulation and cooling units lining the interior walls and ceiling reduce the effective internal width and height compared to a standard dry van of the same external size.

- E-track Systems/Logistics Posts: While essential for securing cargo, these rails mounted on the interior walls can slightly reduce the effective internal width, especially for items that need to be flush against the wall.

- Liftgates/Ramps: While enhancing loading convenience, the mechanism for a liftgate can sometimes slightly intrude into the internal space at the very rear of the truck.

How to Accurately Measure and Verify Internal Dimensions

Never assume or rely solely on advertised dimensions. Always verify:

- Use a Reliable Tape Measure: A long, sturdy tape measure is indispensable.

- Measure at Multiple Points:

- Length: Measure from the inside of the rear door (or just past the door frame) to the front wall.

- Width: Measure at floor level (accounting for wheel wells), mid-height, and near the ceiling. Note the narrowest point.

- Height: Measure from the floor to the lowest overhead obstruction (e.g., ceiling lights, structural beams, or the top of the door frame).

- Check Door Opening Clearances: Measure the exact width and height of the rear door opening. This is often the limiting factor for bulky items.

- Account for Protrusions: Be mindful of wheel wells, e-track systems, and any other internal fixtures that might reduce usable space.

- Verify with Provider: If renting or buying, always ask the provider for detailed internal specifications or, better yet, inspect the actual truck yourself.

Practical Tips for Maximizing Space and Efficiency

Once you know your truck’s internal dimensions, these tips will help you make the most of it:

- Pre-Measure Your Cargo: Don’t guess. Measure your largest items, pallets, and boxes.

- Create a Loading Diagram: For complex loads, sketch out how items will fit. Consider using simple load planning software if available.

- Load Heaviest Items First and Lowest: Place the densest and heaviest items on the floor, ideally centered over the axles for proper weight distribution.

- Stack Strategically: Utilize vertical space by stacking boxes uniformly. Consider interlocking patterns for stability.

- Use Dunnage and Void Fillers: Blankets, moving pads, cardboard, or inflatable air bags can fill empty spaces, prevent shifting, and protect items.

- Secure Your Load: Use tie-downs, ratchet straps, and E-track straps to firmly secure all cargo, preventing movement during transit.

- Consider Pallet Configurations: Standard pallets (48"x40") often fit two abreast in an 8-foot wide truck, but wheel wells can limit this in narrower vehicles.

- Leave Maneuvering Space: While maximizing space, ensure enough room for loading/unloading personnel or equipment.

Challenges and Solutions Related to Internal Dimensions

- Challenge: Misjudging Space Leads to Multiple Trips.

- Solution: Meticulous pre-measurement of both truck and cargo. Add a small buffer (5-10% extra space) for unforeseen items or awkward shapes.

- Challenge: Large Items Won’t Fit Through the Door.

- Solution: Always verify the door opening dimensions, which can be smaller than the interior. For extremely oversized items, consider open-top or flatbed trucks.

- Challenge: Weight Capacity Reached Before Volume is Full.

- Solution: Understand that trucks have both volume (cubic feet) and weight (payload) limits. For dense cargo (e.g., machinery, books), weight is often the limiting factor. Calculate both cubic feet and total weight to ensure compliance.

- Challenge: Cargo Shifting During Transit.

- Solution: Proper loading techniques (heaviest on bottom), even weight distribution, and robust cargo securement using straps, bars, and dunnage.

Typical Straight Truck Internal Dimensions, Capacity & Cost Overview

The following table provides approximate figures for common straight truck sizes, focusing on internal dimensions, typical capacities, and associated costs. These figures are estimates and can vary significantly based on manufacturer, model year, features (e.g., refrigeration, liftgate), and market conditions.

| Truck Size (External Length) | Approx. Internal Length (L) | Approx. Internal Width (W) | Approx. Internal Height (H) | Cubic Feet Capacity (Approx.) | Typical Payload Capacity (lbs) | Avg. Daily Rental Cost (Approx.) | Avg. Purchase Price (New, Approx.) | Best For |

|---|---|---|---|---|---|---|---|---|

| 10 ft Box Truck | 9’10" | 6′ | 6′ | 350-400 cu ft | 2,500 – 3,500 | $70 – $120 | $30,000 – $60,000 | Small apartments, local deliveries |

| 16 ft Box Truck | 15′ | 7′ | 7′ | 700-800 cu ft | 4,000 – 6,000 | $90 – $150 | $50,000 – $90,000 | 1-2 bedroom homes, medium deliveries |

| 20 ft Box Truck | 19′ | 8′ | 8′ | 1,200-1,400 cu ft | 6,000 – 8,000 | $110 – $180 | $70,000 – $120,000 | 2-3 bedroom homes, larger deliveries |

| 24 ft Box Truck | 23′ | 8′ | 8′ | 1,400-1,600 cu ft | 8,000 – 10,000 | $130 – $220 | $80,000 – $150,000 | 3-4 bedroom homes, commercial freight |

| 26 ft Box Truck | 25′ | 8′ | 8’6" | 1,600-1,700 cu ft | 10,000 – 15,000 | $150 – $250 | $90,000 – $180,000 | Large homes, heavy commercial freight |

Note: Rental costs typically vary based on mileage, duration (daily vs. weekly/monthly), and location. Purchase prices are for new vehicles and can fluctuate widely based on chassis, engine, body type (e.g., dry van vs. refrigerated), and additional features. Used truck prices will be considerably lower.

Frequently Asked Questions (FAQ)

Q1: What’s the main difference between internal and external dimensions of a straight truck?

A1: Internal dimensions refer to the usable space inside the cargo compartment (length, width, height of the box). External dimensions refer to the truck’s overall size (bumper to bumper, mirror to mirror, ground to highest point), which is important for maneuverability and clearance, but not for cargo capacity.

Q2: How do wheel wells affect internal dimensions, especially for width?

A2: Wheel wells are protrusions into the cargo area floor, reducing the effective width at those points. This is critical for loading wide items like pallets, which might fit two abreast above the wheel wells but not on the floor in certain areas.

Q3: Do lift gates reduce the internal space of a straight truck?

A3: Generally, no significantly. While the liftgate mechanism is external or integrated into the rear frame, it typically does not reduce the primary internal length, width, or height of the cargo box. However, the door opening dimensions might be slightly affected by the frame surrounding the liftgate.

Q4: Is cubic feet capacity the only thing that matters when choosing a straight truck?

A4: No. While cubic feet (volume) indicates how much space is available, the truck’s payload capacity (weight limit) is equally, if not more, important. You must consider both. For dense items like books or heavy machinery, you might reach the weight limit long before filling the truck’s volume.

Q5: Can I use internal dimensions to estimate how many standard pallets (48"x40") will fit?

A5: Yes, but with caution. A typical 8-foot wide straight truck can fit two 40-inch wide pallets side-by-side (40+40=80 inches, leaving 16 inches for clearance/wheel wells). The length will determine how many rows. Always account for wheel wells, door frame clearance, and the need for maneuvering space.

Q6: Where can I find specific internal dimensions for a truck I’m renting or buying?

A6: Always ask the rental company or dealer for the exact specifications sheet for the specific truck model you are interested in. If possible, measure the truck yourself before committing. Online resources may provide general estimates, but actual truck dimensions can vary.

Q7: What happens if I overload a straight truck based on its internal dimensions or weight limit?

A7: Overloading is dangerous and illegal. It can lead to tire blowouts, brake failure, loss of control, and increased wear and tear on the vehicle. You could face significant fines, impoundment of the vehicle, and liability in case of an accident. Always stay within the truck’s Gross Vehicle Weight Rating (GVWR) and payload capacity.

Conclusion

The internal dimensions of a straight truck are far more than just numbers; they are the blueprint for efficient, cost-effective, and safe logistics. From initial planning and cargo assessment to actual loading and transit, a thorough understanding of these measurements empowers businesses and individuals to make optimal decisions. By accurately assessing your cargo, meticulously verifying truck dimensions, and employing smart loading strategies, you can transform the challenge of transport into a streamlined success. Remember, the right truck size, informed by precise internal dimensions, is the cornerstone of a successful move or delivery.