Parts Of A Lorry: An In-Depth Guide to the Anatomy of a Commercial Vehicle

Parts Of A Lorry: An In-Depth Guide to the Anatomy of a Commercial Vehicle cars.truckstrend.com

From the mighty long-haul giants traversing continents to the nimble delivery trucks navigating urban labyrinths, lorries (or trucks, as they’re commonly known in many parts of the world) are the unsung heroes of global commerce. They transport everything from raw materials and manufactured goods to food and fuel, forming the backbone of supply chains worldwide. But what makes these colossal machines tick? Understanding the intricate "parts of a lorry" is not just for mechanics; it’s crucial for drivers, fleet managers, logistics professionals, and anyone who relies on their vital services.

This comprehensive guide will dismantle the modern lorry piece by piece, exploring its major components, their functions, and why each part plays an indispensable role in ensuring safe, efficient, and reliable transportation.

Parts Of A Lorry: An In-Depth Guide to the Anatomy of a Commercial Vehicle

The Cab: The Driver’s Command Center

The cab is the nerve center of any lorry, serving as the driver’s office, control room, and often, their home away from home. Designed for ergonomics, safety, and comfort, it houses all the necessary controls and instrumentation for operating the vehicle.

- Steering Wheel & Column: Connects the driver to the steering mechanism, allowing precise control over the lorry’s direction. Modern systems often incorporate power steering for ease of maneuverability.

- Dashboard & Instrumentation: A comprehensive display panel featuring gauges for speed, RPM, fuel level, air pressure, temperature, and various warning lights. It also includes controls for lighting, wipers, climate control, and entertainment systems.

- Seats: Ergonomically designed, often air-suspended, to provide comfort and reduce driver fatigue during long journeys. Many feature multiple adjustments for optimal positioning.

- Sleeper Berth (for long-haul lorries): A dedicated sleeping area behind the seats, equipped with a bed, storage, and sometimes a small refrigerator or microwave, essential for drivers on extended routes.

- Pedals: Accelerator, brake, and clutch (for manual transmissions) provide the primary interface for controlling the lorry’s speed and gear engagement.

- Controls & Switches: Levers for gear selection, parking brake, trailer brake, cruise control, mirror adjustments, and more, all strategically placed for easy access.

Practical Insight: A well-maintained and organized cab directly contributes to driver comfort, safety, and alertness, reducing the risk of accidents caused by fatigue or distraction.

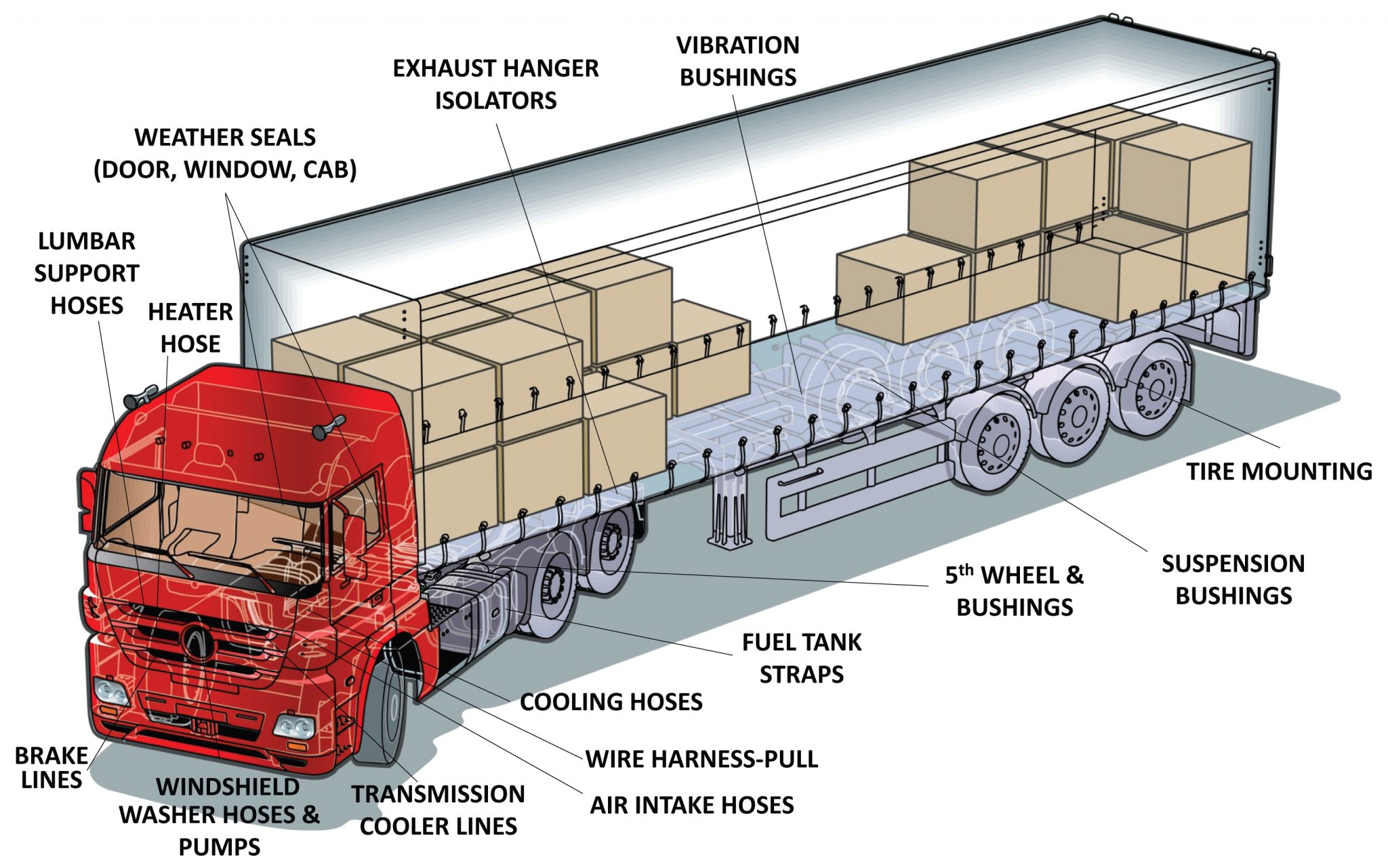

The Chassis: The Backbone of the Beast

The chassis is the fundamental framework upon which all other lorry components are mounted. It’s the skeleton that gives the vehicle its structural integrity and supports the entire weight of the lorry and its cargo.

- Frame: Typically made of heavy-duty steel rails (longitudinal members) and cross-members, designed to withstand immense torsional and bending stresses. Its strength is paramount for load-bearing capacity.

- Suspension System: Connects the wheels to the chassis, absorbing road shocks and vibrations to provide a smoother ride and protect the cargo. It comprises springs (leaf springs, coil springs, or air springs), shock absorbers, and sometimes anti-roll bars. Air suspension is common in modern lorries for its adjustability and ride quality.

- Axles: Solid shafts or housings that connect the wheels, supporting the vehicle’s weight and transferring power to the driving wheels. Lorries have multiple axles (front steer axle, rear drive axles, sometimes additional lift axles) to distribute weight and handle heavy loads.

- Wheels & Tires: Critical for grip, braking, and supporting the load. Lorry tires are specially designed for heavy loads, durability, and often have specific tread patterns for different conditions (e.g., steer, drive, trailer tires). Tire pressure monitoring systems (TPMS) are increasingly common.

Key Consideration: The chassis design and material directly influence a lorry’s maximum load capacity and its ability to handle different terrains. Regular inspection for cracks or deformation is vital.

The Engine: The Heart of the Lorry

The engine is the powerhouse, converting fuel into mechanical energy to propel the lorry. Diesel engines are most common due to their fuel efficiency, torque, and durability, though electric and alternative fuel options are emerging.

- Engine Block & Cylinders: The main structure containing the cylinders where combustion occurs.

- Pistons & Crankshaft: Pistons move up and down within cylinders, driven by combustion, turning the crankshaft, which converts reciprocating motion into rotational motion.

- Fuel System: Includes the fuel tank, fuel pump, fuel lines, injectors, and filters, delivering precisely metered fuel to the engine.

- Air Intake & Exhaust System: Air filters clean incoming air, which is then mixed with fuel. The exhaust system manages the expulsion of combustion gases, including mufflers to reduce noise and catalytic converters/diesel particulate filters (DPFs) to reduce emissions.

- Cooling System: Radiator, water pump, thermostat, and coolant circulate to dissipate heat generated by the engine, preventing overheating.

- Lubrication System: Oil pump, oil filter, and engine oil circulate to lubricate moving parts, reduce friction, and dissipate heat.

Maintenance Tip: Regular oil changes, filter replacements (fuel, air, oil), and coolant checks are paramount for engine longevity and performance.

The Drivetrain: Transmitting Power to the Wheels

The drivetrain is the system that transfers the engine’s power to the driving wheels, enabling the lorry to move.

- Clutch (for manual transmissions): Engages and disengages the engine from the gearbox, allowing for smooth gear changes.

- Gearbox (Transmission): Contains a series of gears that allow the driver to select different ratios for varying speeds and torque requirements. Lorries often have multi-speed transmissions (e.g., 8, 12, or even 18 speeds) to optimize performance for different loads and terrains. Can be manual, automated manual (AMT), or automatic.

- Driveshaft (Propeller Shaft): A rotating shaft that transmits power from the gearbox to the differential.

- Differential: A complex gear assembly located in the drive axle(s) that allows the wheels on the same axle to rotate at different speeds, crucial for turning corners without skidding.

- Axle Shafts: Transmit power from the differential to the individual drive wheels.

Actionable Insight: Proper clutch operation and timely gear changes (especially with manual or AMT systems) can significantly impact fuel efficiency and reduce wear on drivetrain components.

Braking System: Ensuring Stopping Power

Given their immense weight, lorries require highly effective braking systems. Air brakes are standard in heavy commercial vehicles due to their reliability and power.

- Air Compressor: Generates compressed air, which is stored in air tanks (reservoirs).

- Brake Valves: Control the flow of compressed air to the brake chambers.

- Brake Chambers: Convert air pressure into mechanical force to apply the brakes.

- Brake Shoes/Pads & Drums/Discs: The friction components that press against the rotating drums or discs to create friction and slow the vehicle. Disc brakes are becoming more common for their superior heat dissipation and performance.

- Anti-lock Braking System (ABS): Prevents wheels from locking up during heavy braking, allowing the driver to maintain steering control.

- Electronic Braking System (EBS): An advanced system that provides faster and more precise braking response, often integrated with stability control systems.

- Parking Brake: A spring-activated brake that holds the lorry stationary when parked.

Safety First: Regular inspection of brake lines, air tanks, and friction materials is paramount. Any loss of air pressure or spongy brake pedal feel must be addressed immediately.

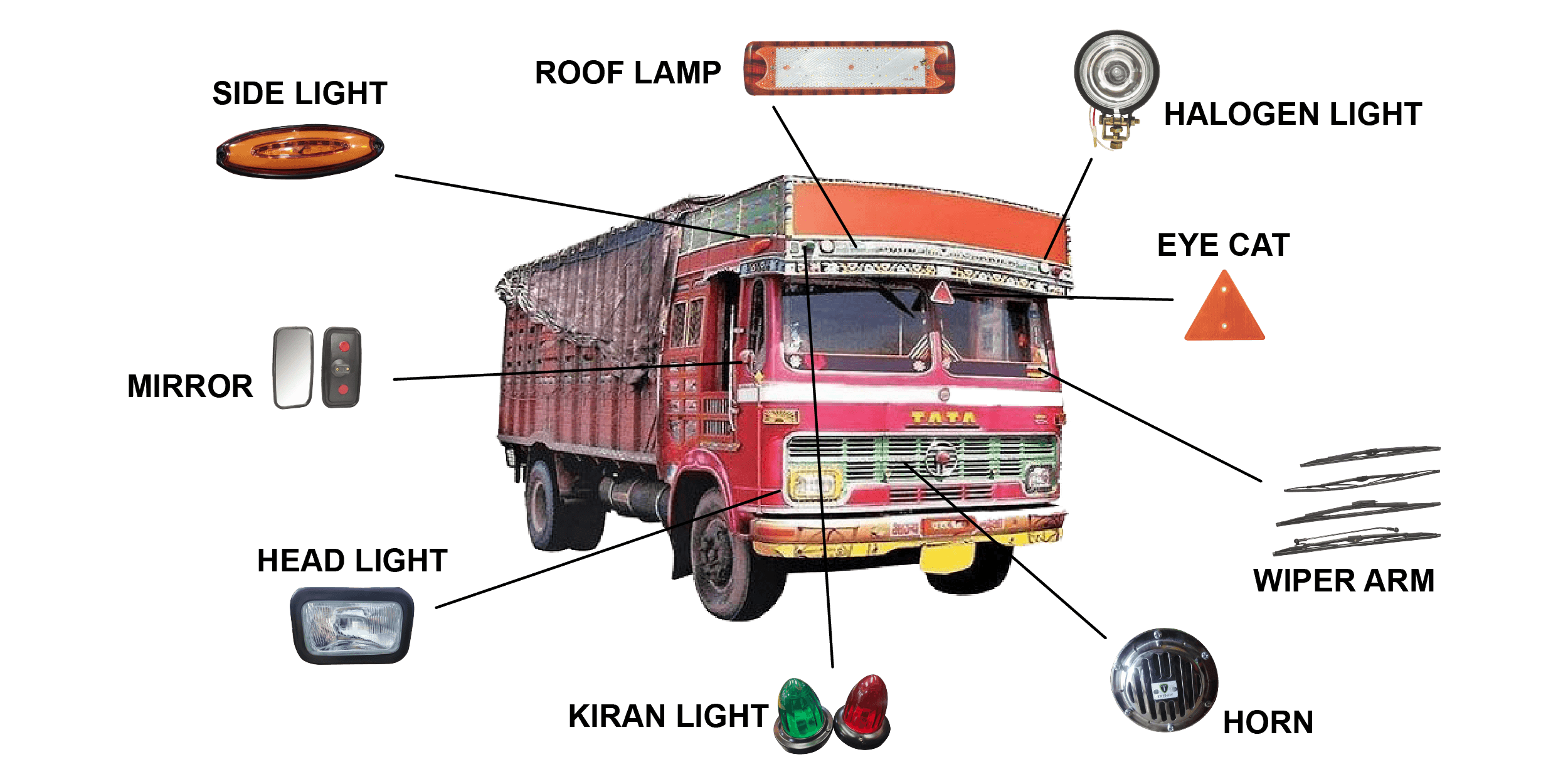

Electrical System: Powering the Modern Lorry

The electrical system is the nervous system of the lorry, powering everything from ignition and lighting to advanced electronic control units (ECUs) and driver assistance systems.

- Battery: Stores electrical energy to start the engine and power auxiliary systems when the engine is off. Lorries typically use multiple heavy-duty batteries.

- Alternator: Charges the battery and supplies power to the electrical system while the engine is running.

- Starter Motor: Uses battery power to crank the engine for ignition.

- Wiring Harnesses: Complex networks of wires connecting all electrical components.

- Lighting: Headlights, tail lights, brake lights, turn signals, marker lights – all essential for visibility and signaling.

- Electronic Control Units (ECUs): Sophisticated computer modules that manage various engine functions, transmission, braking, and other systems, constantly monitoring sensors and adjusting performance.

Consideration: Electrical issues can be notoriously difficult to diagnose. Regular checks of battery terminals, wiring, and fuses can prevent many common problems.

The Trailer/Cargo Area: The Load Carrier

While technically separate, the trailer is an integral "part of a lorry system," as it carries the actual cargo. Its design varies widely based on the goods being transported.

- Fifth Wheel (Coupling Device): A heavy-duty coupling mechanism mounted on the tractor unit (the lorry without the trailer) that allows it to securely attach to and pivot with a semi-trailer.

- Trailer Types:

- Flatbed: Open platform for oversized or oddly shaped cargo.

- Box/Dry Van: Enclosed trailer for general cargo, protecting it from elements.

- Refrigerated (Reefer): Insulated trailer with a refrigeration unit for temperature-sensitive goods.

- Tanker: Cylindrical trailer for liquids or gases.

- Curtain-sider: Combines features of a flatbed and a dry van, with retractable side curtains for easy loading/unloading.

- Lowboy/Low-loader: Designed for extremely tall or heavy equipment.

Practical Advice: Proper coupling and uncoupling procedures are critical for safety. Drivers must always ensure the trailer is securely latched and that all air and electrical lines are correctly connected.

Illustrative Cost Considerations for Lorry Parts

Understanding the cost implications of lorry parts is crucial for fleet management and budgeting. Prices vary wildly based on the lorry’s make, model, year, part type (OEM, aftermarket, used), supplier, and region. The table below provides illustrative ranges for common replacement parts and major components, emphasizing that these are estimates and not definitive prices.

| Part Category | Example Parts Included | Illustrative Price Range (USD) | Key Factors Influencing Price |

|---|---|---|---|

| Engine Components | Injectors, water pump, turbocharger, starter motor | $200 – $5,000+ | Brand (OEM vs. aftermarket), complexity, specific engine model |

| Braking System | Brake pads/shoes, brake drums/rotors, air dryer, valves | $100 – $1,500+ | Material quality, brand, specific brake system type |

| Drivetrain | Clutch kit, driveshaft, universal joints, differential | $300 – $7,000+ | Manual vs. automatic, brand, load capacity |

| Suspension | Air springs, leaf springs, shock absorbers, bushings | $50 – $1,000+ | Type of suspension (air vs. mechanical), brand, axle load |

| Electrical System | Battery, alternator, lights, wiring harnesses, sensors | $50 – $1,000+ | Amperage, specific sensor type, brand, complexity |

| Cab Interior | Seats, dashboard components, switches | $100 – $3,000+ | Material quality, features (e.g., air suspension seat) |

| Tires (per tire) | Drive, steer, trailer tires | $300 – $700+ | Brand, size, tread pattern, ply rating |

| Major Assemblies | Rebuilt engine, transmission assembly, complete axle | $5,000 – $30,000+ | New vs. rebuilt, warranty, brand, complexity |

Note: Labor costs for installation are not included in these part price ranges and can significantly add to the overall expense. Always obtain multiple quotes and consider the long-term value of quality parts.

Frequently Asked Questions (FAQ)

Q1: What is the most critical part of a lorry?

A1: While all parts are interdependent, the braking system is arguably the most critical for safety. A failure here can have catastrophic consequences. The engine and chassis are also fundamentally critical as they enable movement and structural integrity.

Q2: How often should lorry parts be inspected?

A2: Lorries should undergo daily pre-trip inspections by the driver. More detailed preventative maintenance (PM) inspections, as per manufacturer recommendations, are typically performed every 10,000 to 50,000 miles or every few months, depending on the lorry’s usage and type.

Q3: Can I use aftermarket parts for my lorry?

A3: Yes, aftermarket parts are often available and can be more cost-effective than Original Equipment Manufacturer (OEM) parts. However, it’s crucial to choose reputable aftermarket brands that meet or exceed OEM specifications to ensure quality, fit, and safety.

Q4: What are common signs of wear and tear on lorry parts?

A4: Common signs include unusual noises (grinding, squealing, knocking), fluid leaks, excessive smoke from the exhaust, decreased performance (power loss, poor braking), warning lights on the dashboard, and visible damage (cracks, corrosion, excessive play in components).

Q5: How does technology impact lorry parts and maintenance?

A5: Technology has revolutionized lorries. ECUs monitor virtually every system, providing diagnostic codes for quicker troubleshooting. Telematics systems track vehicle performance, location, and maintenance needs. Advanced Driver-Assistance Systems (ADAS) like lane keeping assist and automatic emergency braking rely on sophisticated sensors and control units, adding complexity but enhancing safety. This necessitates specialized diagnostic tools and training for technicians.

Conclusion

The modern lorry is a marvel of engineering, a complex symphony of interconnected parts working in harmony to deliver goods across vast distances. From the driver’s intimate control within the cab to the colossal power generated by the engine, and the robust support provided by the chassis, each component is vital. Understanding the anatomy of a lorry is not merely academic; it empowers drivers to operate safely, fleet managers to optimize maintenance, and businesses to ensure the continuous flow of commerce. By appreciating the intricacies of these mechanical giants, we gain a deeper respect for the critical role they play in our daily lives and the importance of their diligent care and upkeep.