Parts Of A Lorry Body By Name: A Comprehensive Guide

Parts Of A Lorry Body By Name: A Comprehensive Guide cars.truckstrend.com

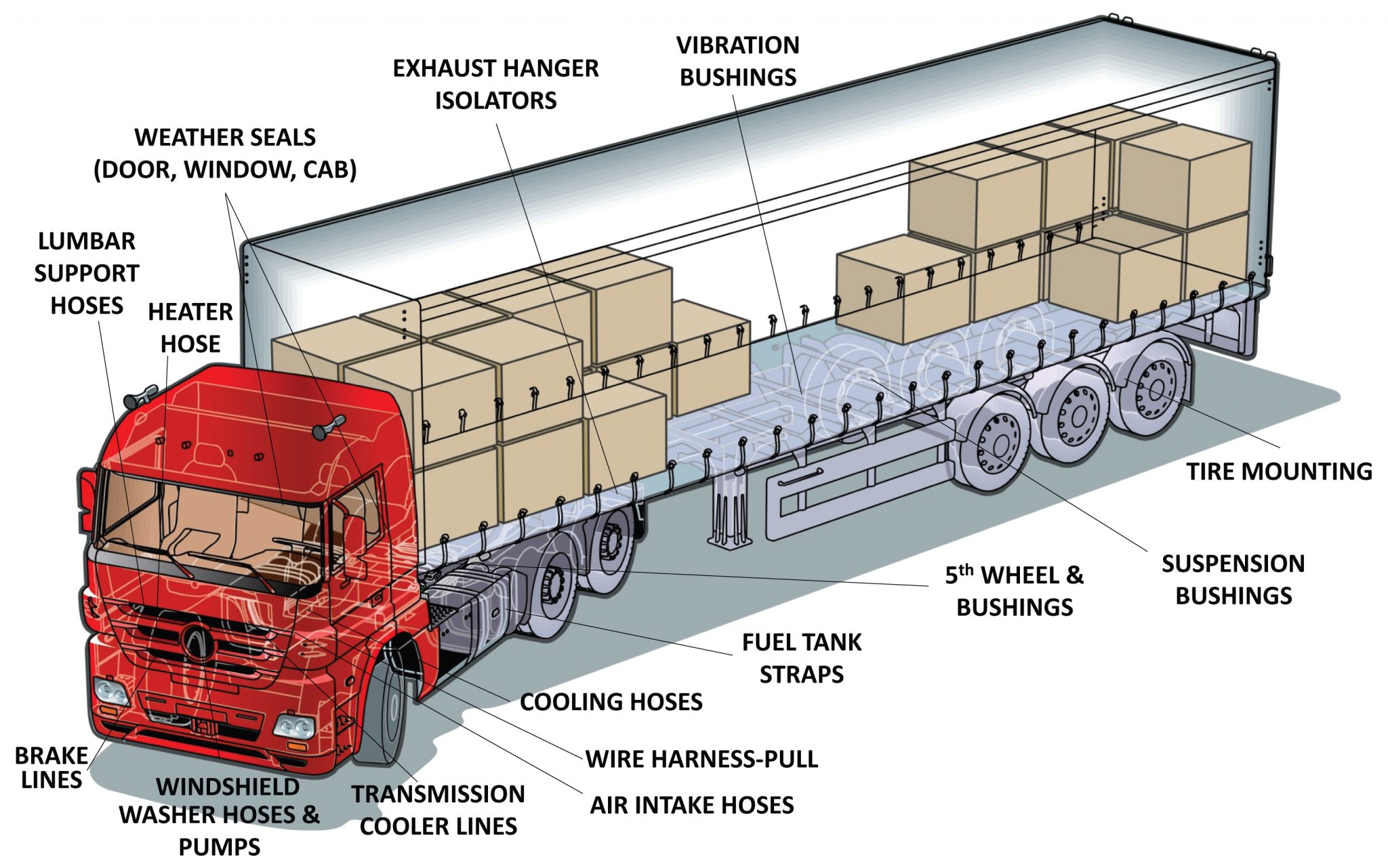

The mighty lorry, an indispensable workhorse of global commerce, is far more than just an engine and wheels. Its robust and meticulously engineered body is what truly defines its function, carrying everything from construction materials to refrigerated goods across vast distances. Understanding the various parts of a lorry body by name is not merely an academic exercise; it’s crucial for effective maintenance, safe operation, efficient logistics, and even for identifying the right vehicle for a specific task.

This comprehensive guide will meticulously break down the anatomy of a lorry body, naming its key components and exploring their significance. Whether you’re a fleet manager, a mechanic, an aspiring driver, or simply curious about these titans of the road, delving into the nomenclature of a lorry’s structure will provide invaluable insights into its design, durability, and diverse capabilities.

Parts Of A Lorry Body By Name: A Comprehensive Guide

The Foundation: Chassis and Frame

At the very core of any lorry is its chassis and frame, serving as the skeletal backbone upon which all other components are mounted. While often used interchangeably, the frame specifically refers to the structural steel beams, typically two parallel longitudinal members connected by several cross members. The chassis, in a broader sense, encompasses the frame along with the engine, drivetrain, axles, suspension, and steering system – essentially everything but the cab and the specific cargo body.

- Longitudinal Members (Frame Rails): These are the two long, heavy-duty steel beams running the length of the lorry, providing the primary structural support. Their strength dictates the lorry’s maximum payload.

- Cross Members: Shorter beams that connect the two longitudinal members horizontally, adding rigidity and preventing twisting.

- Mounting Points: Specific reinforced areas on the frame where the cab, engine, transmission, suspension components, and the cargo body are securely bolted or welded.

- Wheelbase: The distance between the centers of the front and rear axles. A longer wheelbase generally allows for a larger body and more stable load carrying.

Understanding the frame is fundamental because any damage or distortion here can compromise the entire vehicle’s integrity, affecting handling, tire wear, and safety. Regular inspection of mounting points and frame integrity is paramount.

The Driver’s Command Center: The Cab (Cabin)

The cab, or cabin, is the enclosed compartment where the driver operates the lorry. It’s designed for functionality, safety, and increasingly, comfort, given the long hours drivers spend inside.

- Windshield: The large front window providing visibility, often made of laminated safety glass.

- Doors: Access points to the cab, typically robust and equipped with strong hinges and locking mechanisms.

- Roof: The top panel of the cab, often reinforced for safety and sometimes housing air conditioning units or roof lights.

- Side Panels: The outer walls of the cab structure, extending from the doors to the rear of the cabin.

- Rear Wall: The back of the cab, which may be a solid panel or feature a window, especially in day cabs.

- Dashboard/Instrument Panel: The console housing gauges, controls, and infotainment systems. While not a "body part" in the structural sense, it’s integral to the cab’s function.

- Floor Pan: The floor of the cab, often incorporating sound insulation and sometimes a central engine tunnel.

Lorry cabs come in various configurations:

- Day Cab: A smaller cab without sleeping quarters, suitable for local or regional deliveries.

- Sleeper Cab: Features an integrated sleeping berth behind the seats, essential for long-haul operations.

- Crew Cab: Designed to accommodate more passengers, often seen in specialized lorries or those used in construction.

Modern cabs are engineered with crumple zones and robust structures to protect occupants in case of an accident. Their design significantly impacts driver fatigue and overall operational efficiency.

The Workhorse: Cargo Area and Body Types

This is where lorries truly differentiate themselves, with a vast array of body types tailored for specific cargo and applications. Each type has distinct components and operational considerations.

1. Flatbed Body

- Deck (Load Bed): The flat, open platform made of wood, steel, or aluminum, designed for carrying oversized or irregularly shaped cargo.

- Headboard (Bulkhead): A protective barrier at the front of the deck, preventing cargo from shifting forward into the cab during sudden stops.

- Side Raves/Lashing Points: Reinforced edges or rings along the perimeter of the deck, used for securing cargo with straps, chains, or tarpaulins.

- Drop Sides: Optional hinged panels that can be lowered to facilitate loading and unloading from the sides.

2. Box Body / Dry Van

- Side Panels: The rigid walls of the box, typically made of aluminum, fiberglass reinforced plywood (FRP), or steel.

- Front Wall: The solid front panel, often reinforced.

- Roof: The top panel, usually aluminum or translucent FRP for light.

- Floor: The load-bearing surface inside, often made of hardwood, aluminum, or composite materials.

- Rear Doors: Typically swing-out barn doors, roll-up doors, or sometimes a liftgate, providing access to the cargo area.

- Door Frames: The structural framing around the rear door opening.

3. Curtain-Sider Body

- Curtains: Heavy-duty PVC-coated fabric panels that slide open along top and bottom rails, providing quick side access for loading/unloading.

- Roof: Similar to a box body, providing overhead protection.

- Front Bulkhead: A solid front wall.

- Rear Doors: Often barn doors or a full-width opening.

- Pillars/Posts: Vertical supports that provide structural integrity and to which the curtains are secured when closed.

- Tensioners/Buckles: Mechanisms used to pull the curtains taut, securing the load and preventing bulging.

4. Tipper / Dump Body

- Skip / Bucket / Body: The open-top, robust container designed to hold loose materials like sand, gravel, or demolition waste.

- Tailgate: The hinged rear door of the skip, which opens automatically or manually during tipping.

- Scow End: A sloped rear end design that helps material flow out easily.

- Subframe: A secondary frame mounted on the chassis, to which the skip is attached and lifted by the hydraulic system.

- Hydraulic Ram(s): The powerful cylinders that extend to lift the skip for dumping (part of the lifting mechanism, but integral to the body’s function).

Other common body types include:

- Refrigerated Body (Reefer): Insulated box body with an integrated refrigeration unit.

- Tanker Body: Cylindrical or elliptical tank for liquid or gas transport.

- Car Transporter: Multi-level ramps and platforms for vehicle transport.

- Recovery Truck Body: Features a flatbed or boom for towing/transporting disabled vehicles.

The choice of body type directly impacts the lorry’s utility, loading methods, and maintenance requirements.

Essential Exterior and Ancillary Components

Beyond the main structural elements, several other named parts contribute to the lorry body’s functionality, safety, and aesthetics.

- Mudguards (Fenders): Curved covers over the wheels that prevent mud, water, and debris from being thrown up by the tires, protecting other vehicles and pedestrians.

- Bumpers: Protective bars at the front and rear of the lorry, designed to absorb impact in low-speed collisions and protect vital components.

- Side Guards (Underrun Protection): Bars fitted along the sides between the front and rear wheels, preventing cars or pedestrians from going underneath the lorry in a side impact.

- Fuel Tank(s): Large reservoirs for diesel fuel, typically mounted on the side of the chassis, often made of aluminum or steel.

- Battery Box: An enclosure, usually on the side of the chassis, housing the lorry’s batteries.

- Toolboxes / Storage Compartments: Integrated or mounted boxes for carrying tools, chains, and other equipment.

- Lights:

- Headlights: Forward illumination.

- Taillights: Rear illumination and brake lights.

- Indicator Lights: For signaling turns.

- Marker Lights: Small lights along the sides, front, and rear, defining the vehicle’s dimensions, especially at night.

- Mirrors:

- Side Mirrors: Large mirrors on either side of the cab for rear and side visibility.

- Wide-Angle / Convex Mirrors: Smaller, curved mirrors integrated into the main mirrors or mounted separately to reduce blind spots.

- Exhaust System Components (Body Mounted): While part of the engine system, mufflers and tailpipes are often body-mounted and are critical for noise reduction and emissions control.

Practical Advice and Maintenance Tips

Understanding the names of lorry body parts empowers you to maintain them effectively.

- Regular Visual Inspections: Periodically walk around the lorry, checking for dents, cracks, loose fasteners, rust, or damage to any body component. Pay special attention to the chassis, cab mounts, and cargo body integrity.

- Cleanliness and Rust Prevention: Regular washing removes corrosive elements. Promptly address any paint chips or scratches to prevent rust, especially on steel components.

- Check Fasteners and Mounts: Vibration can loosen bolts over time. Ensure all bolts securing the cab, cargo body, fuel tanks, and other components to the chassis are tight and secure.

- Address Damage Promptly: Small cracks or dents can propagate and become major issues if left unaddressed. Timely repairs prevent further deterioration and costly replacements.

- Lubricate Moving Parts: Hinges on doors, tailgates, and curtain mechanisms require regular lubrication to ensure smooth operation and prevent wear.

- Payload Management: Always adhere to the lorry’s maximum payload capacity. Overloading puts undue stress on the chassis, suspension, and cargo body, leading to structural fatigue and potential failure.

Challenges and Solutions

Operating and maintaining lorry bodies comes with its own set of challenges:

- Wear and Tear: Constant use, especially in demanding environments, leads to wear on moving parts and surfaces.

- Solution: Regular maintenance, lubrication, and timely replacement of worn components.

- Corrosion: Exposure to weather, road salt, and chemicals can cause rust, especially in steel components.

- Solution: Protective coatings, galvanization, immediate repair of paint damage, and thorough cleaning.

- Structural Fatigue: Repeated loading/unloading cycles and vibrations can lead to cracks or weakening of the frame and body structure.

- Solution: Adhere to load limits, distribute loads evenly, and conduct regular structural inspections. Professional welding and reinforcement may be necessary for repairs.

- Accidental Damage: Collisions, impacts, or improper loading can cause significant damage to the body panels, doors, or frame.

- Solution: Professional assessment and repair using genuine or high-quality aftermarket parts. Ensure repairs restore structural integrity.

Conclusion

The lorry body, with its myriad named parts, is a marvel of engineering, purpose-built to withstand incredible stresses and fulfill diverse logistical demands. From the fundamental strength of the chassis to the specialized design of various cargo bodies and the intricate details of ancillary components, each part plays a vital role in the lorry’s overall performance, safety, and efficiency.

A thorough understanding of these components not only aids in effective maintenance and troubleshooting but also empowers operators to make informed decisions about vehicle selection and usage. By recognizing the parts of a lorry body by name, we gain a deeper appreciation for the complexity and robust design that allows these vehicles to keep the world moving, day in and day out. Maintaining these parts diligently ensures longevity, safety, and the continued reliability of these essential machines on our roads.

Estimated Price Table for Common Lorry Body Parts

Disclaimer: Prices are highly variable and depend on factors such as lorry make and model, part manufacturer (OEM vs. aftermarket), material, condition (new vs. used), supplier, and current market conditions. These figures are broad estimates for replacement parts and do not include labor costs for installation.

| Part Name | Description | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Cab Shell (Bare) | The main structural body of the cabin, without interior fittings or glass. | $5,000 – $25,000+ | Varies significantly by size (day vs. sleeper) and manufacturer. New OEM can be very expensive. |

| Flatbed Deck (Standard) | Steel or aluminum platform for a 20-30 ft lorry. | $3,000 – $15,000 | Price depends on material, size, and added features like sideboards or specialized flooring. |

| Box Body Side Panel | Single panel for a dry van (e.g., FRP or aluminum). | $500 – $2,500 per panel | Price depends on material, dimensions, and insulation (for reefers). |

| Curtain (PVC) | Heavy-duty PVC curtain for one side of a curtain-sider. | $1,000 – $4,000 per side | Price varies by size, thickness, graphics, and specific rail/tensioner systems. |

| Rear Door Assembly (Pair) | Complete set of rear barn doors for a box body. | $1,500 – $5,000 | Includes doors, hinges, latches, and seals. Roll-up doors can be more expensive. |

| Front Bumper | Aftermarket steel or plastic bumper assembly. | $300 – $2,000 | OEM bumpers, especially for newer models with sensors, can be significantly higher. |

| Rear Mudguard (Single) | Plastic or fiberglass mudguard for a single wheel. | $50 – $300 | Tandem or full-width mudguards will be more expensive. |

| Fuel Tank | Standard capacity (e.g., 100-200 gallons), aluminum. | $500 – $2,500 | Price depends on material (aluminum is lighter but pricier), capacity, and mounting hardware. |

| Headlight Assembly | Complete headlight unit (single side). | $200 – $1,500+ | LED units and integrated DRLs are at the higher end. |

| Side Guard (Per Meter) | Aluminum or steel underrun protection bar. | $50 – $200 per meter | Price varies by material, design, and mounting brackets. |

| Tailgate (Tipper) | Rear door for a tipper body. | $1,000 – $4,000 | Heavy-duty construction, may include hydraulic fittings or locking mechanisms. |

Frequently Asked Questions (FAQ)

Q1: Why is it important to know the names of lorry body parts?

A1: Knowing the names is crucial for effective communication with mechanics, parts suppliers, and insurance companies. It facilitates accurate problem identification, efficient repair processes, proper maintenance, and safer operation. It also helps in understanding the vehicle’s capabilities and limitations.

Q2: What’s the main difference between a lorry’s "chassis" and its "body"?

A2: The chassis is the foundational framework that supports the entire vehicle, including the engine, drivetrain, axles, and suspension. It’s the "skeleton." The body refers to the specific structure mounted on the chassis, such as the cab (driver’s compartment) and the cargo area (e.g., flatbed, box, tanker), designed for specific functions.

Q3: How often should I inspect the lorry body for damage or wear?

A3: A daily pre-trip inspection should include a quick visual check of major body components (lights, mirrors, tires, general condition of the cargo area). More thorough inspections, including checking for rust, cracks, loose fasteners, and structural integrity, should be part of routine maintenance schedules (e.g., weekly, monthly, or during scheduled service intervals).

Q4: Can I customize my lorry body, and what are the limitations?

A4: Yes, many lorry bodies can be customized to suit specific needs, such as adding toolboxes, specialized lighting, or internal shelving. However, any modifications must comply with local regulations regarding dimensions, weight limits, and safety standards. Structural modifications, especially to the chassis, should only be done by certified professionals to maintain the vehicle’s integrity and warranty.

Q5: What are the most common materials used for lorry bodies?

A5: Common materials include:

- Steel: For chassis, heavy-duty frames, tipper bodies, and structural components due to its strength and durability.

- Aluminum: Lighter than steel, used for fuel tanks, side panels, flatbed decks, and some box body components to reduce weight and improve fuel efficiency.

- Fiberglass Reinforced Plastic (FRP): Lightweight and resistant to corrosion, often used for box body panels and some cab components.

- Wood: Used for flatbed decks (hardwood) and some internal flooring in box bodies due to its strength-to-weight ratio and ease of repair.

- PVC (Polyvinyl Chloride): Primarily used for curtains in curtain-sider lorries due to its flexibility, durability, and weather resistance.