Parts Of A Truck: Unraveling the Anatomy of a Workhorse

Parts Of A Truck: Unraveling the Anatomy of a Workhorse cars.truckstrend.com

From the colossal semi-truck traversing continents to the rugged pickup navigating construction sites, trucks are the unsung heroes of modern commerce and daily life. They haul, transport, and deliver, forming the backbone of industries worldwide. But what makes these formidable machines tick? The answer lies in their intricate composition: a complex interplay of thousands of individual parts, each meticulously designed to contribute to the truck’s overall function, safety, and efficiency. Understanding the "Parts Of A Truck" isn’t just for mechanics; it’s crucial for owners, operators, and anyone who relies on these vehicles, enabling better maintenance, informed purchasing decisions, and enhanced safety on the road.

This comprehensive guide will delve into the anatomy of a truck, breaking down its major systems and components. We’ll explore the vital role each part plays, discuss their importance, offer practical insights, and provide a framework for appreciating the engineering marvel that is a truck.

Parts Of A Truck: Unraveling the Anatomy of a Workhorse

The Chassis and Frame: The Unyielding Foundation

At the core of every truck is its chassis and frame, serving as the skeletal structure upon which all other components are mounted. Often referred to as the backbone, the frame provides the necessary rigidity and strength to support the vehicle’s weight, cargo, and withstand the stresses of the road.

- Frame Rails and Crossmembers: Typically made of high-strength steel or aluminum, these form a ladder-like structure. The frame rails run lengthwise, while crossmembers connect them laterally, ensuring torsional stiffness and preventing twisting under load.

- Axles: These robust shafts connect the wheels and support the vehicle’s weight, transferring power to the drive wheels. Trucks have front axles (steering) and rear axles (drive axles, often multiple for heavy loads).

- Importance: The integrity of the frame is paramount. Any damage can compromise the truck’s structural stability, handling, and safety.

- Considerations: Rust prevention is vital, as corrosion can significantly weaken the frame over time. Regular inspections for cracks or bends are essential, especially after heavy impacts or prolonged use under extreme loads.

The Powertrain: The Heartbeat of Motion

The powertrain is the system responsible for generating and delivering power to the wheels, propelling the truck forward. It’s a symphony of interconnected components working in harmony.

1. The Engine: The Powerhouse

The engine is the truck’s literal heart, converting fuel into mechanical energy. For most heavy-duty trucks, diesel engines are the standard due to their torque, fuel efficiency, and durability.

- Key Components:

- Cylinders, Pistons, Crankshaft: Where combustion occurs, driving the crankshaft to produce rotational motion.

- Fuel System: Fuel tank, fuel lines, fuel pump, injectors – deliver fuel to the engine.

- Air Intake System: Air filter, turbocharger/supercharger (for forced induction), intake manifold – supply clean air for combustion.

- Cooling System: Radiator, fan, water pump, thermostat – dissipate excess heat to prevent overheating.

- Lubrication System: Oil pan, oil pump, oil filter – circulate oil to reduce friction and wear.

- Exhaust System: Exhaust manifold, turbocharger, DPF (Diesel Particulate Filter), SCR (Selective Catalytic Reduction), muffler – channel exhaust gases away and reduce emissions and noise.

- Maintenance Tips: Regular oil and filter changes, coolant level checks, air filter replacement, and monitoring warning lights are crucial for engine longevity and performance. Addressing unusual noises or smoke promptly can prevent costly repairs.

2. The Transmission: The Gear Shifter

The transmission manages the power output from the engine, adjusting the torque and speed delivered to the drive wheels.

- Types:

- Manual Transmissions: Require the driver to manually select gears using a clutch pedal and gear stick. Offer greater control and often better fuel economy for experienced drivers.

- Automatic Transmissions: Automatically shift gears, providing ease of operation.

- Automated Manual Transmissions (AMTs): Combine the efficiency of a manual with the convenience of an automatic, common in modern heavy trucks.

- Function: By varying gear ratios, the transmission allows the engine to operate efficiently across different speeds and loads, whether climbing a steep hill or cruising on a highway.

- Considerations: Proper fluid levels and timely fluid changes are vital. Listen for grinding noises or difficulty shifting, which can indicate transmission issues.

3. The Driveline: Power Delivery to the Wheels

The driveline connects the transmission to the drive axles, transmitting rotational power.

- Drive Shaft: A long, rotating tube that transfers power from the transmission to the differential.

- Differential: A critical gear assembly in the axle that allows the wheels on the same axle to rotate at different speeds, essential for turning without tire scuffing.

- Axle Shafts: Connect the differential to the wheels.

- Importance: A well-maintained driveline ensures smooth power delivery and prevents vibrations. U-joints (universal joints) in the drive shaft should be regularly inspected for wear.

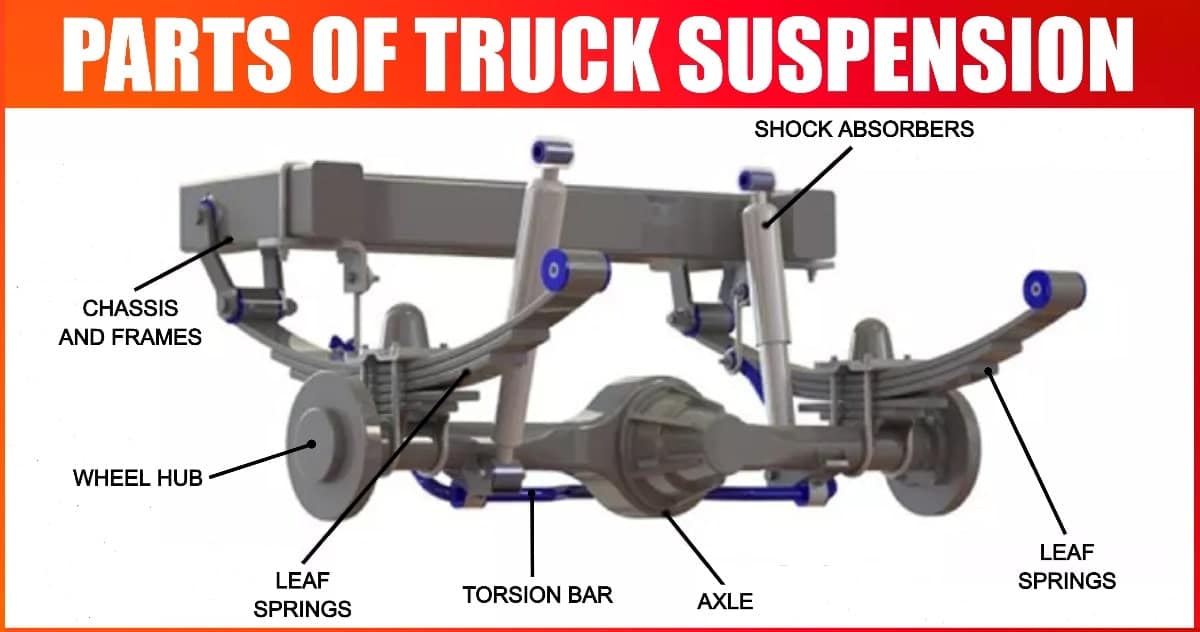

The Suspension System: Cushioning the Ride

The suspension system serves a dual purpose: it absorbs road shocks and vibrations, providing a comfortable ride, and it maintains consistent tire contact with the road, enhancing stability and handling.

- Components:

- Springs: Leaf springs (common for heavy loads), coil springs (for lighter trucks), or air springs (airbags, prevalent in heavy-duty trucks for adjustable ride height and superior ride quality).

- Shock Absorbers/Dampers: Control spring oscillation, preventing excessive bouncing.

- Control Arms and Bushings: Connect the wheels to the frame, allowing controlled movement.

- Sway Bars (Stabilizer Bars): Reduce body roll during cornering.

- Benefits: A good suspension system protects cargo, reduces driver fatigue, and improves vehicle control.

- Maintenance: Check for leaks in air lines or shock absorbers, worn bushings, and cracked or sagging springs.

The Braking System: Paramount for Safety

Perhaps the most critical safety system, the brakes are designed to slow down and stop the truck reliably, even under heavy loads.

- Types:

- Air Brakes: Standard for heavy-duty trucks, using compressed air to actuate the brakes.

- Hydraulic Brakes: Common in light and medium-duty trucks, using hydraulic fluid pressure.

- Key Components (Air Brakes):

- Air Compressor: Generates compressed air.

- Air Tanks: Store compressed air.

- Brake Chambers: Convert air pressure into mechanical force.

- Slack Adjusters: Automatically (or manually) adjust the distance between the brake shoes and the drum.

- Brake Shoes/Pads and Drums/Rotors: The friction components that create the stopping force.

- ABS (Anti-lock Braking System): Prevents wheel lock-up during hard braking, maintaining steering control.

- Safety Considerations: Regular brake inspections, including checking air pressure, brake lining thickness, and proper slack adjuster operation, are non-negotiable. Any sign of reduced braking power, pulling, or unusual noises requires immediate attention.

The Steering System: Precision and Control

The steering system allows the driver to accurately control the truck’s direction.

- Components: Steering wheel, steering column, steering box (or rack and pinion for lighter trucks), power steering pump (for power assistance), tie rods, drag link, kingpins (for heavy trucks).

- Function: Translates the driver’s input from the steering wheel into directional changes of the front wheels. Power steering significantly reduces the effort required.

- Maintenance: Check power steering fluid levels, inspect for leaks, and periodically check linkages for wear or looseness, which can lead to sloppy steering.

The Electrical System: The Truck’s Nervous System

The electrical system powers everything from the ignition and lights to the sophisticated onboard electronics and engine management systems.

- Components:

- Battery: Stores electrical energy for starting and powering accessories when the engine is off.

- Alternator: Charges the battery and powers the electrical system when the engine is running.

- Starter Motor: Engages the engine to start it.

- Wiring Harness: The network of wires connecting all electrical components.

- Lights: Headlights, tail lights, turn signals, marker lights – crucial for visibility and communication.

- ECU (Engine Control Unit) / ECM (Engine Control Module): The "brain" of the engine, managing fuel injection, ignition timing, and emissions.

- Sensors: Monitor various parameters (temperature, pressure, speed) and send data to the ECU.

- Troubleshooting: Common issues include dead batteries, blown fuses, faulty wiring, or sensor malfunctions. Electrical problems can manifest in various ways, from non-starting to erratic gauge readings.

The Cabin and Auxiliary Systems: Driver Comfort and Functionality

While not directly involved in propulsion, these systems are vital for driver comfort, safety, and the overall functionality of the truck.

- The Cabin (Cab): The driver’s workspace, containing the seats, dashboard with gauges and controls, HVAC (heating, ventilation, and air conditioning) system, and often a sleeper berth for long-haul drivers. Ergonomics and visibility are key design considerations.

- Fuel Tank: Stores the fuel, ranging from hundreds of gallons in semi-trucks to smaller capacities in pickups.

- Fifth Wheel: For semi-trucks, this is the coupling device located on the tractor’s frame that securely connects to the kingpin of a semi-trailer, allowing for articulation.

- Tires and Wheels: The only parts of the truck that touch the road. Proper tire inflation, tread depth, and alignment are critical for safety, fuel efficiency, and handling. Different tire types are used for various applications (e.g., steer, drive, trailer tires).

Practical Advice and Actionable Insights

- Embrace Regular Maintenance: This is the golden rule. Adhering to manufacturer-recommended service schedules for fluid changes, filter replacements, and inspections will significantly extend the life of your truck and prevent costly breakdowns.

- Learn the Warning Signs: Pay attention to unusual noises, smells, vibrations, dashboard warning lights, or changes in performance. Early detection of issues can save you time and money.

- Quality Over Cost: When replacing parts, opting for quality OEM (Original Equipment Manufacturer) or reputable aftermarket parts is often a better long-term investment than cheap alternatives that may fail prematurely.

- Know When to DIY vs. Professional: While basic checks (fluid levels, tire pressure) can be done by anyone, complex repairs, especially involving the engine, transmission, or braking system, should be left to certified mechanics.

- Impact on Fuel Efficiency: Well-maintained parts, especially the engine, transmission, and tires, directly contribute to better fuel economy.

- Safety First: Every part of a truck plays a role in its safety. Regular inspections of brakes, lights, steering, and tires are not just about compliance but about protecting lives.

Sample Price Guide for Common Truck Parts

Please note that these prices are highly estimated and can vary dramatically based on the truck’s make, model, year, part brand (OEM vs. aftermarket), new vs. remanufactured, labor costs, and regional availability. This table is for illustrative purposes only.

| Part Category | Specific Part Example | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Engine Components | Diesel Fuel Injector (single) | $200 – $800+ | Varies by engine type, new/reman. |

| Turbocharger | $800 – $3,000+ | New vs. rebuilt, engine size. | |

| Engine Oil Filter | $20 – $80 | Depending on size and type. | |

| Radiator | $300 – $1,500+ | Size, material, truck model. | |

| Transmission | Manual Transmission (reman.) | $2,500 – $8,000+ | Complex part, remanufactured vs. new. |

| Automatic Transmission (reman.) | $3,000 – $10,000+ | More complex, higher range for heavy-duty. | |

| Clutch Kit (manual) | $400 – $1,500+ | Includes disc, pressure plate, release bearing. | |

| Suspension | Air Bag (Air Spring) | $150 – $500 | Single unit, for air suspension systems. |

| Leaf Spring (single) | $100 – $600 | Varies by number of leaves, capacity. | |

| Shock Absorber | $50 – $250 | Per unit, depending on type and application. | |

| Braking System | Brake Drum | $100 – $400 | Per drum, size and material. |

| Brake Shoe Set (per axle) | $80 – $300 | For one axle, includes shoes and hardware. | |

| Air Brake Chamber | $80 – $250 | Per chamber. | |

| ABS Sensor | $50 – $200 | Per sensor. | |

| Steering System | Power Steering Pump | $150 – $500 | New vs. remanufactured. |

| Tie Rod End | $40 – $150 | Per end, inner or outer. | |

| Electrical System | Truck Battery (Heavy-duty) | $100 – $300 | Per battery, often multiple are needed. |

| Alternator | $200 – $700 | New vs. remanufactured. | |

| Starter Motor | $150 – $600 | New vs. remanufactured. | |

| Tires | Commercial Truck Tire | $250 – $600+ | Per tire, varies by size, brand, type (steer, drive, trailer). |

| Miscellaneous | Headlight Assembly | $100 – $500+ | Per side, includes housing and bulbs. |

| Fuel Tank (Large capacity) | $500 – $2,000+ | Varies greatly by size and material. |

Frequently Asked Questions (FAQ)

Q1: How often should I service my truck?

A1: Service intervals vary significantly based on the truck’s make, model, age, type of operation (e.g., long-haul vs. local delivery), and engine type. Always refer to your manufacturer’s recommended maintenance schedule in the owner’s manual. Generally, heavy-duty trucks have service intervals ranging from 10,000 to 25,000 miles for basic maintenance.

Q2: What are the most common parts to fail on a truck?

A2: Common wear-and-tear items include tires, brake components (pads, shoes, drums), filters (oil, fuel, air), batteries, belts, and hoses. For engines, fuel injectors, turbochargers, and emission system components (like DPFs) can be common failure points, especially without proper maintenance.

Q3: Can I use aftermarket parts instead of OEM parts?

A3: Yes, aftermarket parts are often a more affordable alternative to OEM (Original Equipment Manufacturer) parts. However, quality can vary. It’s crucial to choose reputable aftermarket brands that meet or exceed OEM specifications to ensure durability and performance. For critical safety components like brakes or steering, many professionals recommend sticking with OEM or high-quality aftermarket equivalents.

Q4: How do I know if a part needs replacing?

A4: Look for warning signs such as unusual noises (grinding, squealing, clunking), vibrations, fluid leaks, dashboard warning lights, reduced performance (e.g., loss of power, poor braking), visible wear and tear (cracks, excessive rust, worn tread), or changes in handling or ride quality. Regular visual inspections are also key.

Q5: What’s the difference between new, remanufactured, and used parts?

A5:

- New: Brand new, never used, straight from the manufacturer.

- Remanufactured: A used part that has been completely disassembled, cleaned, inspected, worn components replaced, reassembled, and tested to meet original specifications. Often a cost-effective and reliable option for major components like engines or transmissions.

- Used: A part pulled from another vehicle, sold as-is. Cheapest option but carries the most risk regarding reliability and lifespan.

Q6: Why is regular inspection important for truck parts?

A6: Regular inspections allow for the early detection of wear, damage, or potential failures before they become major, costly problems or safety hazards. Proactive maintenance reduces downtime, improves fuel efficiency, extends the truck’s lifespan, and most importantly, ensures the safety of the driver and others on the road.

Conclusion

The modern truck is a testament to sophisticated engineering, a complex tapestry woven from thousands of interconnected parts, each playing a vital role in its function and performance. From the robust frame that bears its immense loads to the intricate electrical system that powers its intelligent features, understanding the "Parts Of A Truck" is fundamental. This knowledge empowers owners and operators to make informed decisions about maintenance, recognize potential issues early, and ultimately ensure the longevity, efficiency, and most critically, the safety of these indispensable workhorses. A well-maintained truck is not just a machine; it’s a reliable partner on the road, ready to tackle any challenge.