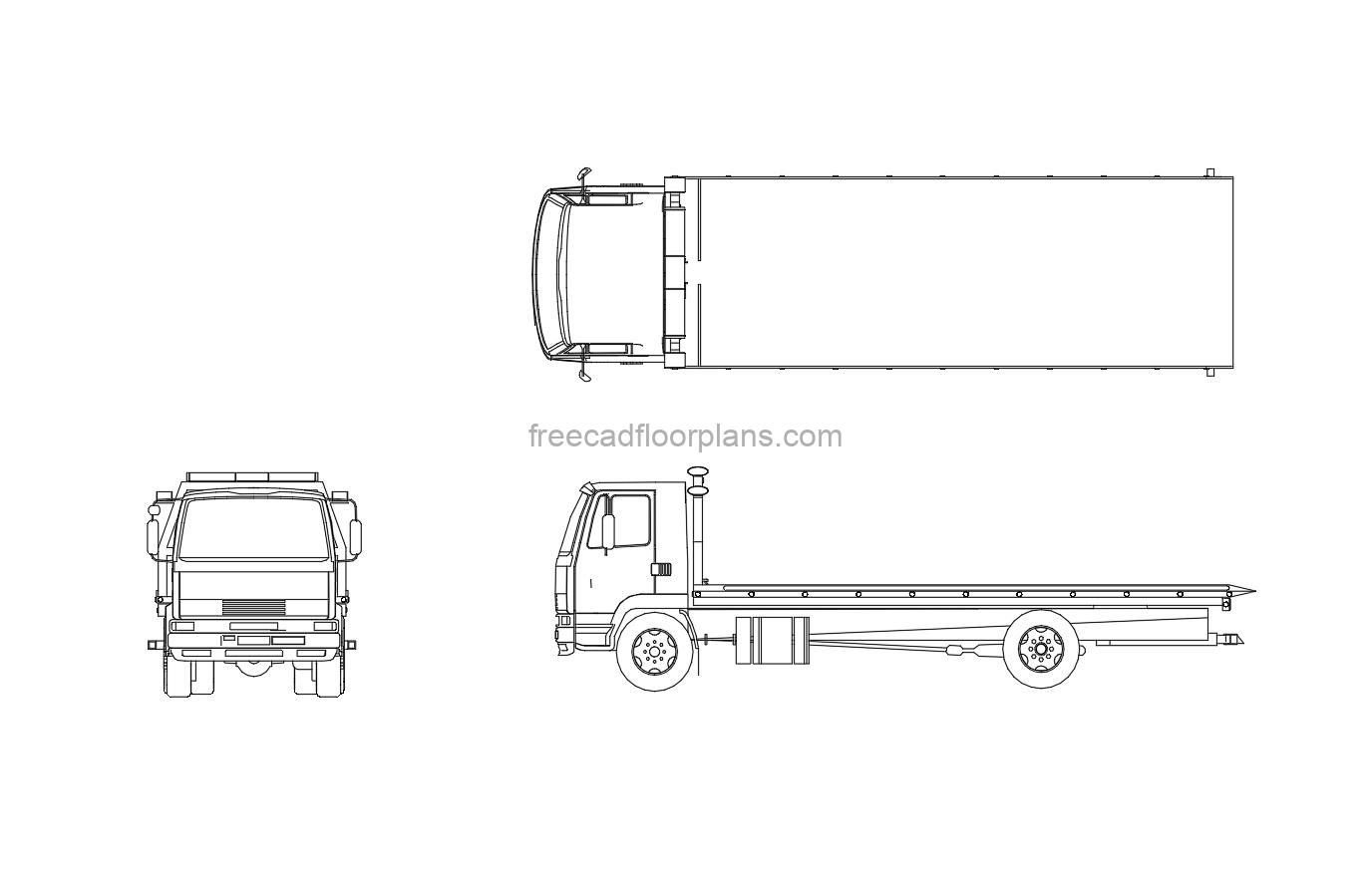

Plans For Flatbed Truck Bed: Transforming Your Truck into a Versatile Workhorse

Plans For Flatbed Truck Bed: Transforming Your Truck into a Versatile Workhorse cars.truckstrend.com

The standard pickup truck bed, while functional, often falls short when it comes to maximizing utility, especially for specialized tasks or oversized loads. This is where the concept of "Plans For Flatbed Truck Bed" truly shines. Far more than just a modification, designing and building a custom flatbed is an investment in versatility, efficiency, and a tailored solution that transforms your truck from a mere hauling vehicle into a highly adaptable work platform or adventure rig.

This comprehensive guide will delve into the intricacies of planning a flatbed truck bed, from initial considerations and material choices to design specifics and practical advice. Whether you’re a DIY enthusiast, a small business owner, or an off-road adventurer, understanding the blueprints for a custom flatbed can unlock your truck’s full potential.

Plans For Flatbed Truck Bed: Transforming Your Truck into a Versatile Workhorse

Why Go Flatbed? Understanding the Benefits

Opting for a flatbed design offers a plethora of advantages over a traditional pickup box, making it a compelling choice for many truck owners:

- Unmatched Versatility: The open, flat surface allows for easier loading and transport of oversized, oddly shaped, or palletized items that simply wouldn’t fit in a standard bed. This includes everything from lumber and machinery to ATVs and custom campers.

- Superior Accessibility: With no sidewalls to contend with, you can load and unload from any angle using forklifts, cranes, or even by hand, significantly streamlining operations.

- Enhanced Customization: A flatbed is a blank canvas. It provides ample space to integrate custom toolboxes, under-deck storage, removable side rails, headache racks, integrated water or fuel tanks, gooseneck hitches, and specialized equipment mounts.

- Increased Durability & Longevity: Often constructed from heavy-duty steel or aluminum, custom flatbeds can be significantly more robust and resistant to damage than factory beds, especially in demanding environments.

- Improved Visibility (Potentially): The lower profile of some flatbeds can offer better rear visibility, especially when not loaded.

- Weight Savings (with Aluminum): While steel flatbeds can be heavier, a well-designed aluminum flatbed can actually reduce overall truck weight, improving fuel economy and increasing payload capacity within the truck’s Gross Vehicle Weight Rating (GVWR).

- Aesthetics and Utility: For many, the rugged, utilitarian look of a flatbed is highly appealing, signaling a truck that’s built for serious work or serious play.

Essential Considerations Before You Begin Planning

Before you even sketch your first line, a thorough understanding of your needs and limitations is paramount. These considerations will dictate the entire design and construction process:

-

Truck Compatibility & Chassis:

- Frame Type: Is your truck’s frame C-channel, boxed, or a hybrid? This affects how the flatbed subframe will be mounted.

- Cab-to-Axle (CA) Length: This critical measurement (distance from the back of the cab to the center of the rear axle) determines the ideal length of your flatbed. Too long, and it might hang excessively past the rear axle; too short, and you lose valuable space.

- Wheelbase: The distance between the front and rear axles influences overall truck stability with a load.

- Gross Vehicle Weight Rating (GVWR): Never exceed your truck’s GVWR, which includes the weight of the flatbed itself, your payload, passengers, and fuel.

-

Intended Use & Payload:

- What will you primarily be hauling? Heavy construction materials, farm equipment, camping gear, ATVs, or a slide-in camper?

- How often will it be used? Daily commercial use demands different durability than occasional recreational use.

- Will you need specific tie-down points, a gooseneck hitch, or integrated storage for tools or recovery gear?

-

Material Selection:

- Steel: The most common choice. Offers exceptional strength, durability, and is relatively easy to weld. However, it’s heavy and susceptible to rust if not properly coated. Ideal for heavy-duty applications.

- Aluminum: Lightweight, corrosion-resistant, and offers excellent strength-to-weight ratio. More expensive than steel and requires specialized welding techniques. Perfect for applications where weight savings are crucial (e.g., overland builds, improved fuel economy).

- Wood: An economical and traditional choice for decking. Requires regular maintenance (sealing, painting) to prevent rot and wear. Can be combined with a steel or aluminum subframe.

- Composite Materials: Emerging options offer unique properties, but are generally more expensive and less common for DIY builds.

-

Budget & Skill Level:

- Budget: Materials (steel, aluminum, decking), hardware, lighting, painting, and potentially specialized tools (welder, plasma cutter) all contribute to the cost. Factor in professional fabrication if you lack the necessary skills or equipment.

- Skill Level: Do you have welding experience? Fabrication knowledge? Electrical wiring skills for lights? Be realistic about what you can accomplish safely and effectively yourself.

-

Legal Requirements & Safety:

- DOT Regulations: Ensure your flatbed complies with federal and state Department of Transportation (DOT) regulations regarding width, length, lighting (tail lights, brake lights, turn signals, marker lights), reflective tape, and load securement.

- Fenders/Mud Flaps: Often legally required to prevent debris from being thrown by tires.

- Load Securement: Plan for adequate tie-down points (D-rings, stake pockets, rub rails) to safely secure your cargo.

- Fuel Filler Relocation: You’ll likely need to extend and relocate your truck’s fuel filler neck.

Key Components of a Flatbed Truck Bed Plan

A well-designed flatbed integrates several critical components that work in harmony to provide strength, utility, and safety:

- Main Frame/Subframe: This is the backbone of your flatbed, attaching directly to the truck’s chassis. Typically constructed from heavy-duty steel tubing or C-channel, it must be robust enough to support the entire load.

- Mounting System: How the subframe attaches to the truck’s frame. This usually involves custom perches, U-bolts, or welded brackets, ensuring a secure, non-flexing connection while allowing for frame flex.

- Decking: The actual flat surface where cargo rests. Common options include steel diamond plate, smooth steel plate, aluminum diamond plate, or treated wood planks. The choice depends on weight, durability, and aesthetic preferences.

- Side Rails & Headache Rack:

- Side Rails: Optional but highly recommended for containing loads. They can be fixed, removable (stake pockets), or fold-down.

- Headache Rack: A vertical structure at the front of the bed, protecting the truck’s cab from shifting cargo. Can also integrate lights, tool mounts, or a spare tire carrier.

- Lighting System: Essential for safety and legality. Includes tail lights, brake lights, turn signals, reverse lights, and side marker lights, all wired to the truck’s existing harness.

- Toolboxes & Storage: Under-deck toolboxes or integrated compartments provide secure storage for tools, chains, or recovery gear, keeping the main deck clear.

- Tie-Down Points: Crucial for load security. Incorporate ample D-rings, stake pockets, rub rails, or winch points strategically around the bed.

- Fuel Filler Neck Relocation: A common necessity, requiring careful planning to ensure proper routing and secure mounting.

- Fenders/Mud Flaps: Designed to cover the rear wheels and prevent road spray and debris from being thrown.

The Planning & Design Process: A Step-by-Step Guide

Embarking on a flatbed build requires meticulous planning. Here’s a structured approach:

-

Measure Your Truck Accurately:

- Measure your truck’s frame width (outside-to-outside).

- Measure the cab-to-axle (CA) length.

- Determine the desired flatbed length and width, considering tire clearance and legal limits.

- Note locations of existing fuel tanks, exhaust, and wiring harnesses that might need relocation or protection.

-

Sketching & Digital Design:

- Start with rough sketches to conceptualize the layout, storage, and desired features.

- Progress to detailed drawings, either by hand with precise measurements or using CAD software (e.g., SketchUp, Fusion 360, AutoCAD). Digital models allow for precise measurements, material optimization, and visualization.

- Calculate material lengths, thicknesses, and angles needed for the subframe, decking, and accessories.

-

Material Sourcing & Budgeting:

- Create a comprehensive materials list based on your design.

- Obtain quotes from local metal suppliers for steel tubing, plate, or aluminum extrusions.

- Price out decking material, hardware (bolts, nuts, washers), wiring, lights, and paint/coating.

-

Tooling & Equipment Assessment:

- Ensure you have (or can rent/borrow) the necessary tools: welder (MIG, TIG, Stick), angle grinder, chop saw or band saw for metal, drill press, clamps, measuring tools, safety gear (PPE).

- If you’re not welding yourself, identify a reputable fabricator.

-

Safety First:

- Always wear appropriate Personal Protective Equipment (PPE): welding helmet, gloves, safety glasses, ear protection, long sleeves/pants.

- Work in a well-ventilated area.

- Have a fire extinguisher readily available when welding or grinding.

- Securely support the truck and any heavy components during installation.

-

Fabrication Steps (Overview):

- Build the Subframe: Cut, fit, and weld the main longitudinal and cross members according to your design. Ensure it’s square and level.

- Mounting System: Fabricate and weld the perches or brackets that will connect the subframe to the truck’s chassis. Ensure proper isolation (rubber pads) if needed to allow for frame flex.

- Decking Installation: Cut and secure your chosen decking material to the subframe.

- Add Accessories: Fabricate and weld the headache rack, side rails, toolboxes, and tie-down points.

- Wiring: Route and connect all lighting according to DOT standards. Use weatherproof connectors and loom.

- Fuel Filler Relocation: Extend and secure the fuel filler neck.

- Fenders/Mud Flaps: Install these for legal compliance and protection.

- Finishing: Grind welds smooth, prepare surfaces, and apply a durable paint or protective coating to prevent rust (for steel) or simply for aesthetics.

Advanced Features & Customizations

Once the basic flatbed is in place, the true potential for customization emerges:

- Integrated Water/Fuel Tanks: Under-deck tanks for extended range or remote water supply.

- Removable Side Panels/Stake Pockets: Allows for quick conversion between a flat deck and a walled bed.

- Gooseneck/5th Wheel Hitch Integration: Essential for heavy towing, seamlessly built into the flatbed structure.

- Underside Spare Tire Carrier: Frees up deck space.

- Roll-Out Drawers/Slides: For easy access to tools or camping gear.

- Integrated Air Compressor/Power Outlets: For on-the-go tire inflation, air tools, or powering accessories.

- Custom Lighting: Rock lights, scene lights, or work lights for improved visibility at night.

Practical Advice and Actionable Insights

- Measure Twice, Cut Once: This old adage is gospel in fabrication. Precision prevents costly mistakes.

- Don’t Underestimate Wiring: It’s often more complex than anticipated. Use quality, weather-resistant components and proper soldering/crimping.

- Professional Welds for Critical Joints: If you’re not an experienced welder, consider hiring a certified professional for the main structural welds. Your safety and payload depend on it.

- Research Local Regulations: State and local laws regarding vehicle modifications can vary. Verify compliance before you build.

- Document Your Build: Take photos and notes. This helps if you need to troubleshoot, explain the build to future buyers, or for insurance purposes.

- Consider Modularity: Design components (like side rails or a headache rack) to be removable or interchangeable if your needs might change.

Concluding Summary

Planning for a flatbed truck bed is an empowering journey that transforms a standard vehicle into a highly specialized tool tailored to your exact needs. From the initial conceptualization and material selection to the intricate details of fabrication and final touches, a well-executed flatbed build enhances your truck’s versatility, durability, and overall utility. Whether it’s for heavy-duty hauling, off-grid adventures, or specialized commercial tasks, the thoughtful planning behind a custom flatbed ensures a robust, efficient, and ultimately, a more capable vehicle. Embrace the challenge, plan meticulously, and enjoy the unparalleled functionality of your personalized flatbed truck.

Table Price: Estimated Cost Breakdown for Flatbed Truck Bed Plans & Builds

Please note: These are estimates and actual costs can vary significantly based on material prices, labor rates, geographical location, specific design complexity, and market fluctuations. "Plans For Flatbed Truck Bed" typically refers to the design and conceptual stage, with the cost of actual construction varying widely.

| Item/Category | Description | Estimated Low Cost (USD) | Estimated High Cost (USD) | Notes |

|---|---|---|---|---|

| Design/Plans | ||||

| DIY (Self-Design) | Time investment, software (e.g., free SketchUp), research. | $0 | $50 | Requires significant personal time and effort. |

| Pre-Made Plans (Online) | Purchased blueprints/CAD files from specialized vendors. | $50 | $300 | Provides detailed cut lists, dimensions, and assembly instructions. |

| Custom Professional Design | Engineering consultation, custom CAD drawings for specific needs. | $500 | $2,500+ | For highly specialized or complex builds requiring professional engineering. |

| Materials (DIY Build) | ||||

| Steel (Subframe & Decking) | Square/rectangular tubing, C-channel, steel plate, diamond plate. | $800 | $2,500 | Strongest, heaviest. Prices vary by gauge and type. |

| Aluminum (Subframe & Decking) | Aluminum tubing, plate, diamond plate. | $1,500 | $4,000 | Lightweight, corrosion-resistant. Higher material cost. |

| Wood (Decking) | Treated lumber, plywood (for sub-deck). | $200 | $600 | Economical decking option, often combined with metal subframe. Requires maintenance. |

| Hardware | Bolts, nuts, washers, self-tapping screws, hinges, latches. | $100 | $300 | Crucial for assembly and functionality. |

| Lighting & Wiring | DOT-compliant LED tail lights, marker lights, wiring harness, connectors. | $150 | $500 | Essential for safety and legality. |

| Paint/Protective Coating | Primer, topcoat (e.g., automotive paint, bed liner, epoxy). | $100 | $400 | Rust prevention and aesthetics. |

| Fuel Filler Neck Kit | Extension hose, clamps, mounting bracket. | $50 | $150 | Necessary for fuel tank access. |

| Fenders & Mud Flaps | Steel, aluminum, or plastic fenders; rubber mud flaps. | $100 | $400 | Legally required in many areas. |

| Optional Accessories | ||||

| Headache Rack | Steel or aluminum fabrication. | $200 | $800 | Cab protection, often includes light mounts. |

| Under-Deck Toolboxes | Steel or aluminum, various sizes. | $300 (per pair) | $1,500+ (custom) | Secure storage for tools and equipment. |

| Tie-Down Points | D-rings, stake pockets, rub rails. | $50 | $250 | Essential for cargo securement. |

| Gooseneck/5th Wheel Prep | Integrated mounting points, heavy-duty structure. | $300 | $1,000 | For heavy towing applications. |

| Labor (If Outsourced) | ||||

| Basic Fabrication & Install | Professional shop to build and install a standard flatbed. | $2,500 | $6,000 | Based on simple design, basic materials. |

| Custom/Complex Fabrication | Professional shop for specialized designs, advanced features, premium materials. | $6,000 | $15,000+ | Highly customized, intricate welding, premium finishes. |

Total Estimated Costs:

- Basic DIY Build (Materials Only): $1,500 – $4,500

- Mid-Range DIY Build (Materials + Some Specialized Tools): $2,500 – $7,000

- Professional Custom Build (Design + Materials + Labor): $3,000 – $15,000+

Frequently Asked Questions (FAQ)

Q1: Is it legal to build my own flatbed truck bed?

A1: Generally, yes, it is legal to build your own flatbed, but you must adhere to federal and state Department of Transportation (DOT) regulations regarding vehicle modifications. This includes ensuring proper lighting, reflective tape, overall vehicle width/length, load securement, and potentially requiring a safety inspection. Always check your local vehicle modification laws.

Q2: How long does it typically take to build a custom flatbed?

A2: For a DIY builder with moderate fabrication skills, a basic flatbed can take anywhere from 40 to 160 hours (1-4 weeks of dedicated work). A professional shop can complete a standard build in a few days to two weeks, depending on complexity and their schedule.

Q3: What’s better for a flatbed: steel or aluminum?

A3: It depends on your priorities.

- Steel: Stronger, more affordable, easier to weld for most DIYers, but heavier and prone to rust if not properly coated. Ideal for heavy-duty work and budget builds.

- Aluminum: Lightweight (improves payload, fuel economy), corrosion-resistant, but more expensive and requires specialized welding techniques (TIG or spool gun MIG). Ideal for overland builds, weight-sensitive applications, or where rust is a major concern.

Q4: Do I need a professional welder to build my flatbed?

A4: For critical structural welds on the subframe and mounting system, it is highly recommended to have a professional, certified welder perform the work unless you are an experienced and confident welder yourself. The integrity of these welds directly impacts safety and payload capacity. Non-structural components like toolboxes or side rails can be tackled by a less experienced welder.

Q5: How much weight can a custom flatbed hold?

A5: The weight capacity of your flatbed is limited by several factors: the design and materials of the flatbed itself, the strength of its mounting to the truck’s frame, and most importantly, your truck’s Gross Vehicle Weight Rating (GVWR) and Gross Axle Weight Ratings (GAWRs). Never exceed your truck’s manufacturer-specified ratings, as this can lead to safety hazards, vehicle damage, and legal issues.

Q6: Do I need to inform my insurance company about the flatbed modification?

A6: Yes, it is highly advisable to inform your insurance company about any significant modifications to your truck, including installing a custom flatbed. This ensures that your vehicle remains properly covered in case of an accident or theft. Failure to disclose modifications could lead to claim denials.

Q7: Can I convert my existing pickup bed into a flatbed?

A7: While you can remove the existing bed, you cannot simply convert it into a flatbed. A flatbed requires a dedicated subframe that mounts directly to the truck’s chassis, and a completely new flat deck surface. The original bed is not designed to serve as a flatbed structure.