Sewer Cleaning Trucks For Sale: Your Comprehensive Guide to a Vital Investment

Sewer Cleaning Trucks For Sale: Your Comprehensive Guide to a Vital Investment cars.truckstrend.com

The intricate network of underground pipes that forms our sewer systems is the unseen backbone of modern civilization. From residential waste to industrial byproducts, these conduits transport vast quantities of wastewater, preventing public health crises and environmental contamination. However, like any complex system, sewer lines are prone to blockages, corrosion, and wear, necessitating regular maintenance and, often, emergency intervention. This is where sewer cleaning trucks, robust and specialized pieces of machinery, come into play.

For municipalities, private contractors, industrial facilities, and utility companies, acquiring a sewer cleaning truck isn’t just a purchase; it’s a strategic investment in efficiency, public health, and environmental stewardship. Whether you’re looking to expand your service offerings, enhance your operational independence, or replace aging equipment, understanding the market for "Sewer Cleaning Trucks For Sale" is paramount. This comprehensive guide will navigate the complexities of these essential vehicles, from their fundamental types and benefits to critical buying considerations and practical advice for making a wise investment.

Sewer Cleaning Trucks For Sale: Your Comprehensive Guide to a Vital Investment

Understanding the Core: What Are Sewer Cleaning Trucks?

Sewer cleaning trucks are purpose-built vehicles designed to maintain, clean, and clear blockages within underground piping systems. While they vary significantly in size, capacity, and functionality, they generally fall into three primary categories: hydro-jetting trucks, vacuum trucks, and combination units.

1. Hydro-Jetting Trucks (Jetters)

Hydro-jetting trucks, often simply called "jetters," utilize high-pressure water to dislodge and flush out debris, grease, roots, and other obstructions from sewer lines.

- How They Work: A powerful water pump draws water from an onboard tank and delivers it through a high-pressure hose to specialized nozzles. These nozzles create powerful water streams (up to 4,000 PSI or more) that cut through blockages and scour pipe walls, pushing material downstream.

- Applications: Ideal for routine pipe cleaning, preventative maintenance, removing grease buildup in restaurant lines, cutting through stubborn root intrusions, and clearing smaller, localized clogs.

- Benefits: Highly effective at cleaning pipe walls, environmentally friendly (uses water), can navigate complex pipe systems.

2. Vacuum Trucks (Vactors/Sucker Trucks)

Vacuum trucks, also known as Vactors (a common brand name) or sucker trucks, are designed to suction up liquids, sludge, debris, and solid waste from various sources.

- How They Work: Equipped with a powerful vacuum pump, these trucks create a strong suction force that pulls material through a large diameter hose into a dedicated debris tank. The vacuum system can handle a wide range of materials, from standing water to heavy sludge and even small solids.

- Applications: Essential for cleaning catch basins, storm drains, lift stations, septic tanks, industrial sumps, spill cleanups, and removing accumulated debris after jetting operations.

- Benefits: Excellent for removing large volumes of material, effective for wet and dry debris, crucial for post-jetting cleanup.

3. Combination Units (Combo Trucks)

Combination units are the workhorses of the sewer cleaning industry, integrating both hydro-jetting and vacuum capabilities into a single vehicle.

- How They Work: These trucks feature separate water tanks for jetting and large debris tanks for vacuuming. They are equipped with both high-pressure water pumps and powerful vacuum pumps, allowing operators to simultaneously jet and vacuum, or perform each function independently.

- Applications: The most versatile option, perfect for comprehensive sewer line cleaning where both dislodging and removal of debris are necessary. They are indispensable for emergency response, large-scale municipal projects, and complex industrial cleanups.

- Benefits: Unmatched versatility, increased efficiency (one truck does the job of two), reduced operational costs, ideal for a wide range of tasks.

Beyond these core functionalities, most trucks include features like hydraulic hose reels, remote control systems, boom arms for easier hose positioning, and various safety components.

Why Invest? Benefits of Owning a Sewer Cleaning Truck

The decision to purchase a sewer cleaning truck is driven by significant operational and financial advantages.

For Municipalities and Public Works Departments:

- Proactive Maintenance & Emergency Response: Own equipment allows for scheduled preventative maintenance, reducing emergency call-outs and catastrophic failures. When emergencies do occur (e.g., major blockages, flooding), immediate response is possible without relying on external contractors.

- Cost Savings: Eliminates ongoing contractor fees, leading to substantial long-term savings.

- Public Health & Environmental Protection: Ensures efficient waste removal, preventing overflows, environmental pollution, and the spread of waterborne diseases.

- Control & Flexibility: Full control over scheduling, staffing, and project priorities.

For Private Contractors and Businesses:

- Service Expansion & Revenue Generation: Opens up new revenue streams by offering specialized sewer and drain cleaning services to residential, commercial, and industrial clients.

- Operational Independence: No reliance on rented equipment or subcontractors, ensuring consistent availability and quality of service.

- Increased Efficiency & Profitability: Owning the right equipment improves job completion times and overall project profitability.

- Customization: Ability to outfit trucks with specific features and tools tailored to niche markets (e.g., grease trap cleaning, hydro excavation).

For Industrial Facilities:

- On-Site Maintenance: Allows for immediate attention to process line blockages, sumps, and containment areas, minimizing downtime and maintaining compliance.

- Waste Management: Efficiently manage and dispose of industrial wastewater and sludge.

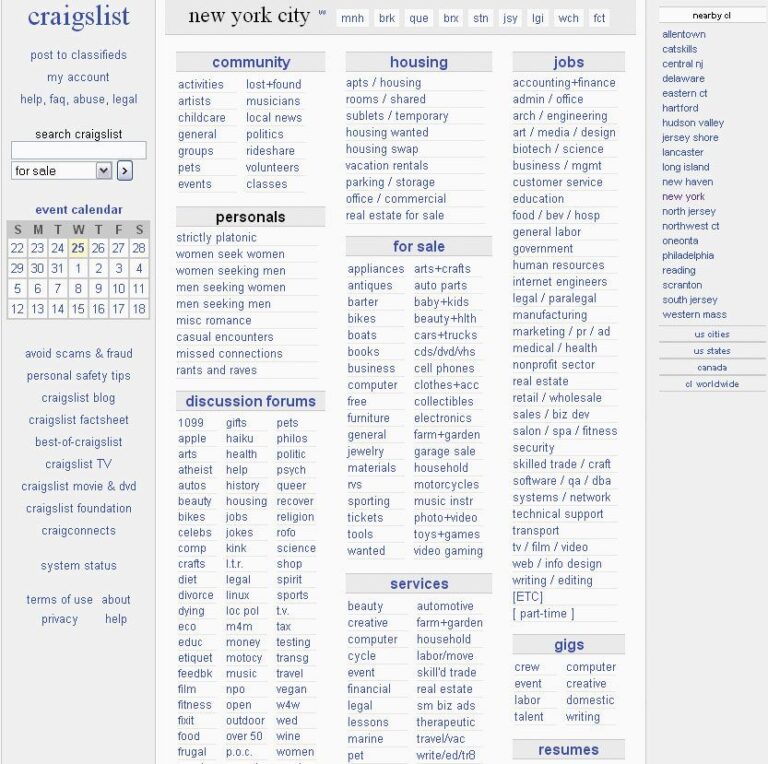

Navigating the Market: Where to Find Sewer Cleaning Trucks For Sale

The market for sewer cleaning trucks is diverse, offering options for every budget and operational need.

- New Trucks: Purchased directly from authorized dealers or manufacturers (e.g., Vactor, Ramvac, Vac-Con, Super Products, Sewer Equipment Co. of America).

- Benefits: Latest technology, full warranty, customizable features, manufacturer support, often more fuel-efficient and reliable.

- Considerations: Highest initial cost.

- Used Trucks: Available through various channels, offering significant cost savings.

- Sources: Online heavy equipment marketplaces (e.g., TruckPaper, MachineryTrader, GovPlanet), specialized equipment brokers, public auctions (municipal surplus), direct sales from other contractors or businesses.

- Benefits: Lower upfront cost, quicker acquisition.

- Considerations: Potential for wear and tear, unknown maintenance history, older technology, limited or no warranty. Thorough inspection is crucial.

- Refurbished Trucks: Some specialized dealers offer fully reconditioned trucks, often with updated components and a limited warranty.

- Benefits: A middle ground between new and used, offering better reliability than an "as-is" used truck at a lower price than new.

- Considerations: Cost is higher than typical used, but less than new. The quality of refurbishment varies.

Key Considerations When Buying a Sewer Cleaning Truck

Making an informed purchase requires careful evaluation of several factors:

-

Application and Intended Use:

- Will you primarily be clearing small residential drains, large municipal sewer mains, or industrial lines? This dictates required pump power, tank capacity, and maneuverability.

- Are you focused on preventative maintenance, emergency response, or specialized tasks like hydro excavation?

-

Truck Size and Capacity:

- Debris Tank Size: (e.g., 500 to 3,000+ gallons) Determines how much material can be collected before needing to offload. Larger tanks mean fewer trips to the disposal site, increasing efficiency for big jobs.

- Water Tank Size: (e.g., 500 to 1,500+ gallons) Affects how long you can jet before refilling.

- Chassis Size and Weight: Ensure it can handle the load and is suitable for your typical operating environment (e.g., tight urban streets vs. open industrial sites).

-

Pump Specifications:

- Water Pump (for Jetters/Combos): Measured in Gallons Per Minute (GPM) and Pounds per Square Inch (PSI). High GPM is good for flushing large pipes; high PSI is good for cutting through tough blockages like roots. Common ranges: 60-100 GPM at 2000-2500 PSI for municipal, or higher PSI for specialized cutting.

- Vacuum Pump (for Vac Trucks/Combos): Measured in Cubic Feet per Minute (CFM) and Inches of Mercury (Hg). Higher CFM means faster suction; higher Hg indicates stronger pulling power for dense materials. Common ranges: 3000-6000+ CFM at 15-28" Hg.

-

Features and Accessories:

- Hose Reels: Hydraulic vs. manual, capacity, front vs. rear mounted.

- Boom Arm: Articulating boom for easy hose positioning, especially for catch basin cleaning.

- Winterization System: Essential for cold climates to prevent freezing of water lines and tanks.

- Remote Controls: Enhance safety and efficiency by allowing operators to control functions from a distance.

- Camera Systems: Rearview and possibly pipe inspection cameras.

- Filtration Systems: For vacuum trucks, to protect the pump and ensure clean exhaust.

- Safety Features: Strobe lights, backup alarms, emergency stops.

- Auxiliary Hydraulics: For powering additional tools.

-

Chassis and Engine:

- Manufacturer: Popular chassis brands include Freightliner, Peterbilt, Kenworth, International.

- Engine: Diesel engines are standard for their torque and durability. Consider horsepower and fuel efficiency.

- Transmission: Automatic transmissions are common for ease of operation.

- Drive Configuration: 4×2, 6×4, or even 6×6 depending on terrain and load requirements.

-

Maintenance History (Crucial for Used Trucks):

- Request detailed service records. Look for consistent oil changes, filter replacements, and pump maintenance.

- Inspect for rust, frame damage, tire wear, and fluid leaks.

- Check pump hours and engine hours – these indicate wear more accurately than mileage.

- Ideally, have an independent mechanic perform a pre-purchase inspection.

-

Budget and Financing:

- Beyond the sticker price, factor in operating costs (fuel, maintenance, insurance, disposal fees) and potential financing interest.

- Explore leasing options or commercial loans.

-

Training and Support:

- Does the manufacturer or dealer offer training for operating and maintaining the truck?

- Is there readily available parts supply and a service network for repairs?

Tips for a Successful Purchase

- Define Your Needs Clearly: Before you even start looking, list out the specific jobs you’ll be doing, the environments you’ll be operating in, and your budget.

- Research Thoroughly: Compare brands, models, and features. Read reviews and talk to other operators.

- Inspect Meticulously (Especially Used): Don’t just kick the tires. Run the pumps, test all controls, check for leaks, and listen for unusual noises.

- Verify Documentation: Ensure clear title, service records, and any necessary certifications.

- Test Drive: Operate the truck and its equipment under conditions similar to your intended use if possible.

- Factor in Total Cost of Ownership: Beyond the purchase price, consider fuel, maintenance, insurance, and the cost of disposal for collected waste.

- Negotiate: Don’t be afraid to haggle, especially on used equipment.

Challenges and Solutions

- High Initial Cost:

- Solution: Explore the robust used and refurbished markets, or consider financing/leasing options to spread the cost.

- Maintenance Complexity:

- Solution: Implement a rigorous preventative maintenance schedule, train your operators on daily checks, and establish relationships with qualified heavy equipment mechanics.

- Operator Training:

- Solution: Invest in comprehensive training programs for your staff, covering both operation and safety protocols. Many manufacturers offer training courses.

- Regulatory Compliance:

- Solution: Stay updated on local, state, and federal regulations regarding waste disposal, emissions, and safety (e.g., OSHA). Ensure your truck meets all necessary standards.

- Market Fluctuations:

- Solution: Be patient and monitor the market. Good deals can appear unexpectedly.

Sewer Cleaning Trucks For Sale: Estimated Price Table

Please note: These are estimated price ranges and can vary significantly based on brand, year, condition, features, capacity, engine hours, and market demand. New trucks are often highly customizable, influencing final cost.

| Truck Type | Capacity Range (Water/Debris) | Key Features (Typical) | New Price Range (Est.) | Used Price Range (Est.) |

|---|---|---|---|---|

| Hydro-Jetting Truck | 500-1500 gal water | 60-100 GPM @ 2000-4000 PSI pump, hydraulic hose reel, various nozzles, remote control | $150,000 – $350,000+ | $40,000 – $150,000+ |

| Vacuum Truck | 1000-4000 gal debris | 3000-6000+ CFM @ 15-28" Hg vacuum pump, filtration, boom arm, hoist/dump capabilities | $200,000 – $450,000+ | $60,000 – $250,000+ |

| Combination Unit | 1000-1500 gal water / 1000-2000 gal debris | Both high-pressure jetting and high-volume vacuum systems, boom arm, hydraulic reels, remote | $350,000 – $650,000+ | $100,000 – $400,000+ |

Prices are for the truck body and equipment, not including the chassis, which is integrated.

Specialized units (e.g., for hydro excavation, hazardous waste) can exceed these ranges.

Frequently Asked Questions (FAQ) about Sewer Cleaning Trucks For Sale

Q1: What is the typical lifespan of a sewer cleaning truck?

A1: With proper maintenance, a sewer cleaning truck can last 15-25 years or more. The lifespan depends heavily on the quality of the original build, the intensity of use, and the regularity of maintenance. Pumps and engines are often the first components to require major overhauls or replacement.

Q2: What are the main operating costs for these trucks?

A2: Key operating costs include fuel (diesel), routine maintenance (oil changes, filter replacements, hydraulic fluid), wear parts (hoses, nozzles, vacuum filters), major repairs (pump overhauls, engine work), insurance, and the cost of disposing of collected waste.

Q3: Do I need a special license to operate these trucks?

A3: In most regions, a Commercial Driver’s License (CDL) with appropriate endorsements (e.g., air brakes, tanker endorsement due to liquid capacities) is required to operate these heavy vehicles, especially if they exceed certain weight limits. Always check local and federal regulations.

Q4: Can I customize a new sewer cleaning truck?

A4: Absolutely. New sewer cleaning trucks are highly customizable. Manufacturers offer a wide range of options for pump specifications, tank sizes, hose reels, boom types, remote controls, winterization packages, and safety features to meet specific operational needs.

Q5: What’s better: buying new or used?

A5: It depends on your budget, immediate needs, and risk tolerance. New trucks offer reliability, warranty, and the latest technology but come at a high cost. Used trucks are more affordable but require thorough inspection and carry a higher risk of unexpected repairs. Refurbished trucks offer a middle ground.

Q6: How often should these trucks be serviced?

A6: Regular preventative maintenance is crucial. This typically includes daily visual checks, weekly lubrication, monthly fluid checks and filter cleaning, and more comprehensive quarterly or annual inspections and servicing of the engine, pumps, hydraulics, and electrical systems. Follow the manufacturer’s recommended service schedule.

Q7: What safety precautions are essential when operating a sewer cleaning truck?

A7: Essential safety precautions include wearing appropriate PPE (gloves, eye protection, hard hat, safety footwear), proper training on equipment operation and emergency procedures, maintaining safe distances from high-pressure hoses, ensuring proper ventilation in confined spaces, and adhering to lockout/tagout procedures during maintenance. Awareness of the risks associated with hazardous waste is also critical.

Conclusion

Investing in a sewer cleaning truck, whether new or used, is a significant decision that impacts your operational capabilities, financial health, and ability to serve your community or clients effectively. These specialized vehicles are indispensable tools for maintaining critical infrastructure, safeguarding public health, and protecting the environment.

By thoroughly understanding the different types of trucks, carefully evaluating your specific needs, and diligently researching the market, you can make an informed purchase that will yield substantial returns for years to come. With proper maintenance and skilled operation, a sewer cleaning truck isn’t just a piece of equipment; it’s a powerful asset that keeps the vital arteries of our modern world flowing freely.