The Mobile Workshop: Unpacking the Farrier Truck

The Mobile Workshop: Unpacking the Farrier Truck cars.truckstrend.com

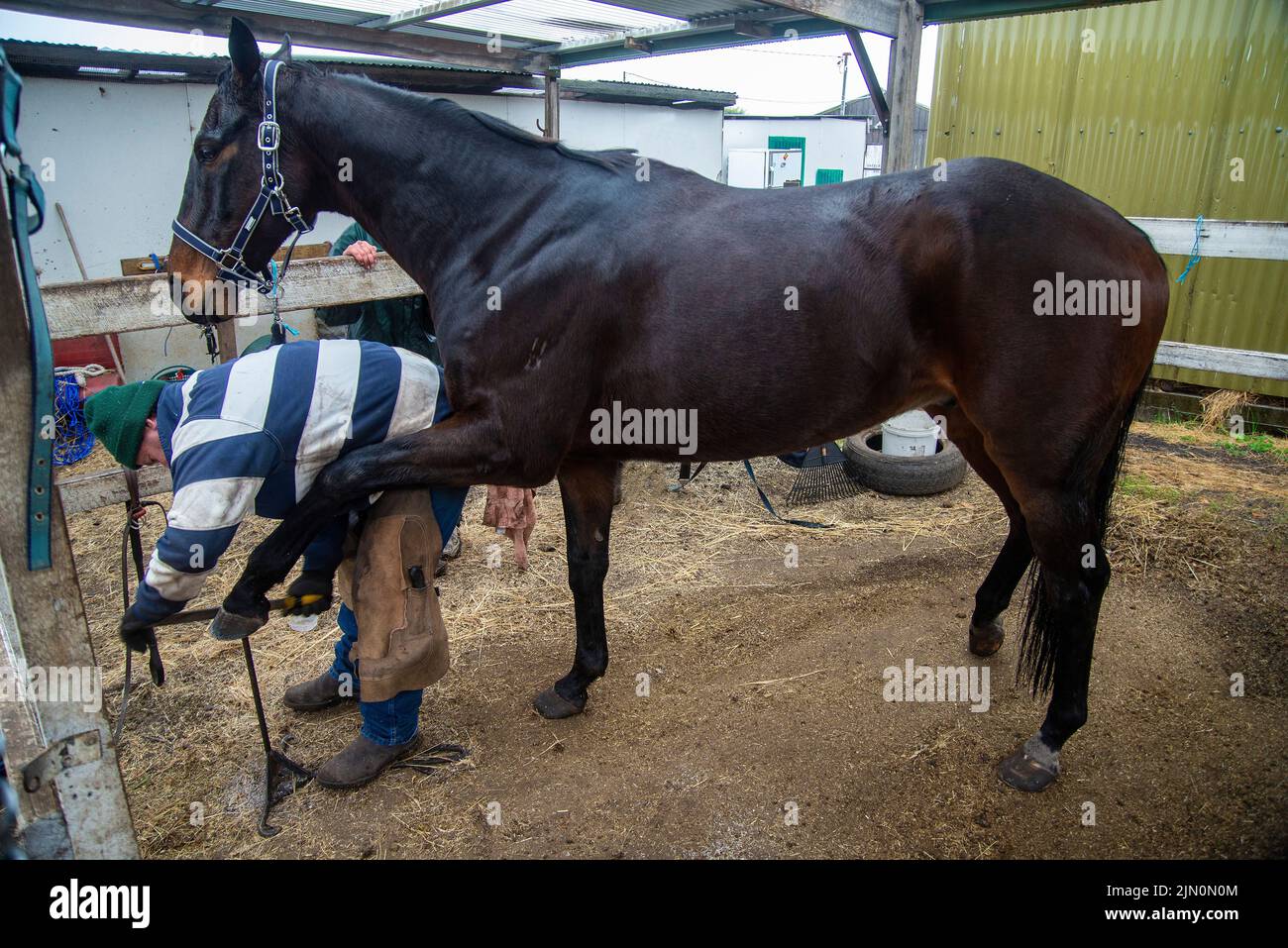

In the world of equine care, few professions are as vital and demanding as that of the farrier. These skilled artisans are the backbone of hoof health, shaping and fitting horseshoes to ensure the comfort, performance, and longevity of our equine companions. But unlike a stationary blacksmith, a modern farrier’s workshop is often on wheels – a meticulously organized and highly specialized vehicle known as the Farrier Truck. More than just a means of transport, the farrier truck is a mobile forge, a comprehensive tool chest, and a vital lifeline that allows farriers to deliver their essential services directly to horses in stables, barns, and even remote pastures. It represents efficiency, professionalism, and the very essence of modern equine hoof care, transforming a traditional craft into a dynamic, on-location service.

What Defines a Farrier Truck?

The Mobile Workshop: Unpacking the Farrier Truck

At its core, a farrier truck is a purpose-built or extensively modified vehicle designed to carry all the necessary tools, equipment, and supplies a farrier needs to perform their work remotely. It’s not just about transporting items; it’s about creating a functional, safe, and efficient workspace wherever a horse might be. While the specific setup can vary widely based on individual preference, budget, and specialization, a true farrier truck is characterized by its thoughtful organization and integration of specialized equipment. This mobile workshop allows farriers to maintain a high level of professionalism and productivity, saving valuable time and effort by bringing the entire operation to the client.

Why the Farrier Truck is Indispensable

The evolution of the farrier truck mirrors the increasing demands placed on farriers today. Its indispensability stems from several key benefits:

- Mobility and Reach: Horses are not always easily transportable. A farrier truck allows the farrier to reach clients in diverse locations, from sprawling ranches to small backyard stables, offering unparalleled convenience.

- Efficiency and Productivity: With everything organized and easily accessible, farriers can work more efficiently. No time is wasted searching for tools or setting up temporary workstations. The integrated nature of the truck means less setup and pack-up time per client.

- Professionalism and Image: A well-equipped and organized farrier truck projects a professional image, instilling confidence in clients. It demonstrates preparedness, commitment, and a serious approach to the craft.

- Safety and Organization: Dedicated storage for sharp tools, heavy equipment, and hot items minimizes hazards. Everything has its place, reducing the risk of accidents on the job site.

- Weather Protection: Working outdoors is often unavoidable. The truck provides shelter for tools and equipment, protecting them from the elements and ensuring their longevity.

- Client Comfort: The ability to work efficiently and with all necessary tools on hand often translates to a quicker, less stressful experience for the horse and its owner.

Key Components and Essential Features

A fully functional farrier truck is a symphony of specialized components, each playing a crucial role in the daily operations:

- The Vehicle Base: This can range from a heavy-duty pickup truck with a custom bed insert or topper, to a commercial van, or even a small trailer towed by a conventional vehicle. The choice depends on the amount of equipment, the terrain frequently encountered, and budget.

- Forge and Fuel Storage: The heart of the farrier’s work, a propane or gas-fired forge is essential for heating horseshoes to make precise adjustments. Safe, ventilated storage for propane tanks is paramount.

- Anvil and Stand: A sturdy anvil, often weighing 70-150 pounds or more, requires an equally robust stand that can be securely mounted or easily deployed and stable during use.

- Tool Storage and Organization: This is where the farrier truck truly shines. Custom drawers, shelves, racks, and bins are designed to hold various nippers, rasps, hammers, tongs, clinchers, buffers, and specialty tools, keeping them sharp, clean, and accessible.

- Power Sources: Many modern tools require electricity. This can be supplied by a generator (mounted or portable), an inverter system powered by the truck’s battery, or shore power at the client’s location if available.

- Lighting: Good lighting, both interior and exterior, is crucial for early morning, late evening, or overcast work, and for illuminating the hoof area.

- Vise: A heavy-duty bench vise, often mounted on a pull-out or swing-out arm, is indispensable for holding shoes, bending steel, and performing various adjustments.

- Grinders and Sanders: Electric or pneumatic grinders are used for shaping, finishing, and sharpening tools. Proper ventilation and dust collection are important considerations.

- Hoof Stand and Cradle: Portable stands designed to support the horse’s hoof at various heights, reducing strain on the farrier.

- Specialized Compartments: Dedicated spaces for new shoes (various sizes and types), nails, pads, hoof dressings, first-aid supplies for both horse and farrier, and administrative items.

- Waste Management: Bins for old shoes, hoof trimmings, and other debris help maintain a clean work environment and comply with client expectations.

- Safety Equipment: Fire extinguisher, first-aid kit, eye protection, ear protection, and appropriate work gloves are non-negotiable.

Types of Farrier Truck Setups

Farrier truck setups generally fall into a few categories:

- Basic Utility Setup: Often a pickup truck with a bed-mounted toolbox or cap, suitable for farriers just starting out or those with a smaller client base and less specialized equipment. Organization relies heavily on portable bins and boxes.

- Custom Pickup Bed/Service Body: This is the most common. A standard pickup truck chassis is fitted with a specialized bed that includes integrated storage compartments, pull-out drawers, and often dedicated areas for the forge, anvil, and power tools. These can be custom-fabricated or purchased as pre-made service bodies.

- Van Conversion: Commercial vans (e.g., Sprinter, Transit) offer an enclosed, climate-controlled workspace. They provide excellent security for tools and can be highly customized with shelving, workbenches, and power systems.

- Farrier Trailer: For those who prefer to keep their daily driver separate or need a larger, more stable workspace, a custom-built trailer can be an excellent option. These often feature full stand-up height, extensive storage, and robust power systems.

Designing and Building Your Farrier Truck

Designing a farrier truck is a highly personal process that requires careful planning:

- Assess Your Needs: What type of work do you do? How many horses per day? What tools are essential? Do you work in all weather conditions?

- Budget: This will significantly influence your choices, from the vehicle itself to the level of custom fabrication.

- Layout and Workflow: Plan the placement of your forge, anvil, and tools for ergonomic efficiency. Imagine yourself performing a shoeing job – where do you need things to be?

- Weight Distribution: Heavy items like the anvil, forge, and propane tanks should be positioned to maintain proper vehicle balance and prevent overloading axles.

- Ventilation and Safety: Ensure adequate ventilation for the forge and any grinding operations. Include mounts for a fire extinguisher and clear pathways.

- DIY vs. Professional Build: Many farriers custom-build their setups, saving money and tailoring it precisely. Others opt for professional fabricators specializing in mobile workshops, which offers a higher quality finish and expert engineering.

Maintenance and Longevity

A farrier truck is a significant investment and a critical asset. Regular maintenance is key to its longevity and reliability:

- Vehicle Maintenance: Standard oil changes, tire rotations, brake checks, and fluid top-offs are essential. Pay extra attention to suspension components due to the heavy loads carried.

- Equipment Care: Regularly clean and lubricate tools. Sharpen nippers and rasps. Inspect hoses and connections on your forge.

- Organization and Cleaning: Keep the truck tidy. Dust and debris can damage tools and electronics. Regular cleaning prevents rust and wear.

- Safety Checks: Periodically inspect all mounts, straps, and securing devices for the forge, anvil, and other heavy equipment. Check fire extinguisher pressure.

Operational Considerations

- Client Site Logistics: Always consider where you’ll park at a client’s property. Is there level ground? Sufficient space? Access to power if needed?

- Noise and Fumes: Be mindful of noise from generators or grinders, especially in residential areas. Ensure forge fumes dissipate safely.

- Waste Disposal: Have a plan for disposing of hoof trimmings, old shoes, and other waste responsibly.

Legal and Safety Aspects

- Vehicle Regulations: Ensure your truck complies with all local and national vehicle weight, registration, and safety regulations.

- Insurance: Adequate commercial vehicle insurance is crucial to protect your investment and cover liability.

- Fire Safety: Beyond the extinguisher, understand the risks associated with propane, hot metal, and sparks. Keep flammables away from the forge.

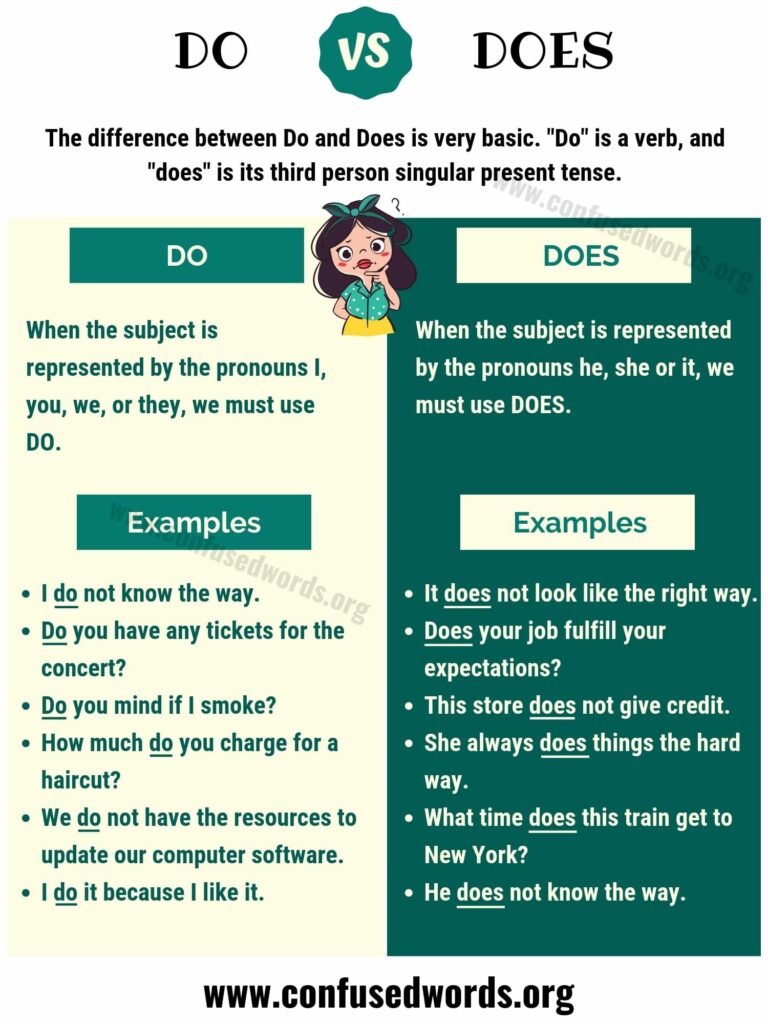

Farrier Truck Estimated Price Guide

Please note: Prices are highly variable based on new vs. used, brand, customization level, and geographic location. These are estimates for a functional setup.

| Component Category | Description | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Vehicle Base | Used Heavy-Duty Pickup Truck (F-250/350, Ram 2500/3500, Silverado/Sierra 2500/3500) | $20,000 – $50,000+ | Depends heavily on mileage, year, condition. New trucks can easily exceed $60,000-$90,000+. Van conversions (Sprinter/Transit) can be similar or higher. |

| Custom Build/Outfitting | Basic Bed Insert/Topper with shelving | $3,000 – $10,000 | Pre-fabricated inserts, basic shelving, and tool organization. |

| Professional Custom Service Body/Van Conversion | $15,000 – $40,000+ | Highly customized compartments, integrated forge/anvil mounts, power systems, lighting. Can go much higher for bespoke builds. | |

| Core Equipment | Propane Forge (portable/mounted) | $500 – $2,500 | Single or double burner, brand, and features. |

| Anvil (new, 70-150 lbs) | $800 – $2,500+ | Quality of steel, weight, and brand. Used anvils can be cheaper but harder to find. | |

| Anvil Stand (custom or commercial) | $200 – $800 | Sturdy, adjustable, and secure. | |

| Post Vise (large, mounted) | $300 – $1,000+ | New or refurbished. | |

| Grinder/Buffer (bench or portable) | $200 – $1,000 | Depending on size, power, and brand. | |

| Power & Lighting | Generator (portable or mounted) | $800 – $3,000 | Inverter generators are quieter. Size depends on power needs. |

| Inverter/Battery System (for vehicle power) | $500 – $2,000 | For running smaller tools directly from truck battery. | |

| Interior/Exterior LED Lighting | $100 – $500 | Essential for safety and visibility. | |

| Hand Tools & Consumables | Basic Farrier Tool Set (nippers, rasps, hammers, tongs, clinchers) | $1,500 – $4,000+ | High-quality tools are an investment. Can be built up over time. |

| Hoof Stands/Cradles (set of 2) | $200 – $500 | Various designs and materials. | |

| Assorted Horseshoes, Nails, Pads, Hoof Dressings (initial stock) | $500 – $2,000+ | Ongoing expense, initial stock can be substantial. | |

| Safety Equipment | Fire Extinguisher, First-Aid Kit, Eye/Ear Protection | $100 – $300 | Non-negotiable. |

| Labor (if professional build) | Fabrication and Installation Labor | $5,000 – $20,000+ | Can vary widely based on complexity and shop rates. |

| Total Estimated Cost | (Vehicle + Customization + Equipment) | $25,000 – $100,000+ | A basic, functional setup can start lower, while a fully custom, new vehicle build can easily exceed $100,000. |

Frequently Asked Questions (FAQ)

Q1: Do I really need a dedicated farrier truck if I’m just starting out?

A1: While not strictly necessary on day one, a well-organized vehicle that can safely transport your essential tools is critical. Many farriers start with a simpler setup (e.g., a pickup with a toolbox) and gradually upgrade as their business grows and they understand their specific needs better.

Q2: What’s better, a truck with a service body or a van conversion?

A2: Both have pros and cons. Service bodies on trucks offer open-air access, often better ground clearance, and a rugged image. Vans provide an enclosed, often climate-controlled, and more secure workspace, ideal for harsh weather or urban environments. The best choice depends on your work environment and personal preference.

Q3: How do I ensure my forge is safe in the truck?

A3: Always secure propane tanks in a well-ventilated, upright position, preferably in a dedicated, external compartment. Ensure the forge itself is securely mounted and has proper heat shielding. Always allow the forge to cool completely before driving, and never transport it with gas lines attached if it’s a portable unit. A fire extinguisher rated for gas fires is a must.

Q4: How do I power my tools on the road?

A4: The most common solutions are a portable or mounted generator (gasoline or propane) or an inverter system connected to your truck’s battery. Inverters are quieter for smaller tools but drain the battery, while generators offer more sustained power for heavy-duty tools.

Q5: Can I build my own farrier truck setup?

A5: Absolutely! Many farriers are skilled tradespeople and choose to build their own setups. This allows for maximum customization and can save significant money. However, it requires time, welding/fabrication skills, and a good understanding of vehicle dynamics and safety. If you’re unsure, consulting with or hiring a professional fabricator is advisable.

Conclusion

The farrier truck is far more than just a vehicle; it is the mobile heart of a modern farrier’s business. It embodies the blend of traditional craftsmanship with contemporary efficiency, enabling these essential professionals to deliver their vital services wherever a horse may need them. From the roar of the forge to the precision of a rasp, every element within this mobile workshop is designed to optimize performance, ensure safety, and project professionalism. Investing in a well-designed and maintained farrier truck is an investment in the longevity of a career, the health of horses, and the continued excellence of a time-honored trade. It is truly a testament to the dedication and ingenuity of farriers, bringing the forge to the hoof, one horse at a time.