Tri Axle Dump Truck Capacity: A Comprehensive Guide

Tri Axle Dump Truck Capacity: A Comprehensive Guide cars.truckstrend.com

In the demanding world of construction, mining, and material transport, the efficiency and legality of hauling operations hinge significantly on one critical factor: dump truck capacity. Among the diverse fleet of heavy-duty vehicles, the tri-axle dump truck stands out as a workhorse, offering a versatile balance of payload capability and maneuverability. Understanding "Tri Axle Dump Truck Capacity" isn’t merely about knowing how much material a truck can carry; it’s about comprehending the complex interplay of engineering, legal regulations, material science, and operational strategy that dictates how much it should carry for optimal performance, safety, and profitability.

This comprehensive guide will delve deep into the nuances of tri-axle dump truck capacity, exploring its various facets from defining metrics and influencing factors to practical calculation methods and strategies for optimization. Whether you’re a fleet manager, owner-operator, or simply someone seeking to understand the backbone of material transport, mastering the concept of capacity is paramount to success in the aggregates industry.

Tri Axle Dump Truck Capacity: A Comprehensive Guide

Understanding Tri-Axle Configurations

A tri-axle dump truck is distinguished by its axle configuration: typically, one steer axle at the front and two drive axles at the rear, often coupled with a third, additional axle (either a lift axle or a tag/pusher axle) positioned behind or in front of the drive tandem. This additional axle serves a crucial purpose: to distribute weight more evenly over a longer wheelbase, thereby increasing the Gross Vehicle Weight Rating (GVWR) and complying with "bridge laws" that regulate the maximum weight allowed on specific lengths of a vehicle’s wheelbase.

This multi-axle setup allows the truck to legally carry heavier loads than a tandem-axle truck, making it ideal for hauling bulk materials like sand, gravel, asphalt, dirt, and demolition debris over varying distances. The ability to lift the third axle when unladen or lightly loaded reduces tire wear and improves maneuverability, particularly in tight spaces.

Key Metrics of Capacity

When discussing tri-axle dump truck capacity, two primary metrics come into play: payload weight and volumetric capacity. Understanding both is essential for efficient and legal operation.

1. Payload Weight (Tonnage)

Payload weight refers to the actual weight of the material the truck is legally allowed to carry. This is the most critical metric as it directly impacts profitability and legal compliance.

- Gross Vehicle Weight Rating (GVWR): This is the maximum operating weight of a vehicle as specified by the manufacturer, including the vehicle’s chassis, body, engine, fuel, driver, and payload. For a tri-axle dump truck, GVWR typically ranges from 60,000 to 79,000 pounds (approximately 30 to 39.5 tons), though specific state regulations often cap it at 80,000 lbs (40 tons) without special permits.

- Gross Axle Weight Rating (GAWR): This refers to the maximum weight that can be supported by a single axle or axle group. Tri-axle trucks have GAWRs for the steer axle, the tandem drive axles, and the additional lift/tag axle. Overloading any single axle can lead to fines and safety hazards, even if the overall GVWR is not exceeded.

- Tare Weight (Unladen Weight): This is the weight of the truck itself when empty, including fuel and a driver. The lower the tare weight, the more payload the truck can carry within its legal GVWR. Tare weights for tri-axle dump trucks can vary significantly based on the manufacturer, engine, chassis material, and especially the dump body material (steel vs. aluminum). Typical tare weights range from 28,000 to 35,000 pounds (14 to 17.5 tons).

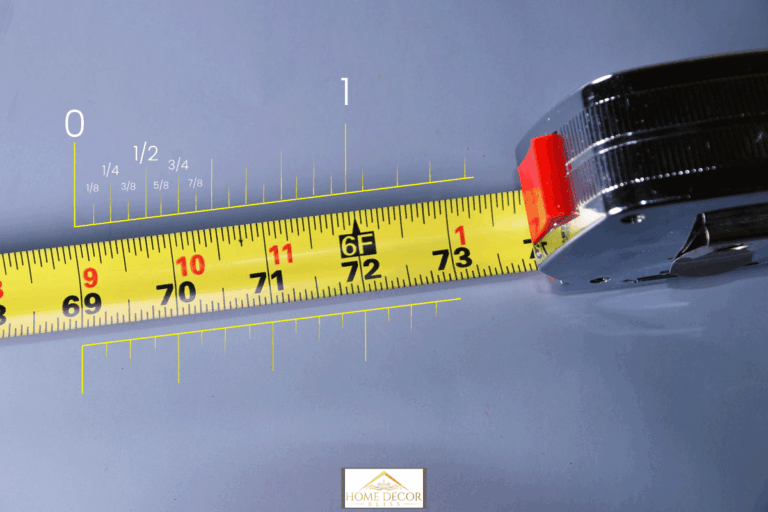

To calculate the maximum legal payload weight, you subtract the truck’s tare weight from its legal GVWR:

Maximum Payload = Legal GVWR – Tare Weight

2. Volumetric Capacity (Cubic Yards/Meters)

Volumetric capacity refers to the volume of the dump body, typically measured in cubic yards (or cubic meters internationally).

- Struck Capacity: This is the volume of the dump body when the material is level with the top of the side walls.

- Heaped Capacity: This accounts for the material piled above the side walls at a natural angle of repose. Heaped capacity is generally 15-25% greater than struck capacity.

Tri-axle dump truck bodies typically range from 16 to 22 cubic yards (struck), with heaped capacities extending up to 25-28 cubic yards. While volumetric capacity dictates how much space is available, it’s crucial to remember that dense materials will hit the weight limit long before they fill the entire volume. Conversely, very light materials might fill the body to its heaped capacity without exceeding the weight limit.

Factors Influencing Tri-Axle Dump Truck Capacity

Several critical factors interact to determine the practical and legal capacity of a tri-axle dump truck.

1. Truck Specifications and Components

- Engine Power and Transmission: While not directly affecting legal capacity, sufficient power and a robust transmission are essential to efficiently move heavy loads, especially on inclines.

- Frame Strength and Suspension: These components must be designed to withstand the stresses of heavy payloads. Higher-rated components contribute to a higher potential GVWR.

- Axle Ratings (GAWRs): The load ratings of the steer axle, drive axles, and any auxiliary axles are paramount. A truck’s GVWR is ultimately limited by the sum of its axle ratings and bridge law compliance.

- Tare Weight: As discussed, lighter truck components (e.g., aluminum wheels, lighter frame materials) directly increase available payload.

2. Dump Body Design and Material

- Material (Steel vs. Aluminum): Steel bodies are robust and durable but significantly heavier, reducing payload capacity. Aluminum bodies are much lighter, allowing for greater payload, but typically have higher upfront costs and may be less durable for abrasive materials.

- Dimensions: The length, width, and side height of the dump body directly determine its volumetric capacity.

- Wall Thickness and Floor Design: Thicker materials offer greater durability but add weight.

3. Material Being Hauled

The density of the material is arguably the most significant real-world factor limiting payload.

- High-Density Materials: Materials like crushed stone, asphalt, and dense sand will quickly reach the truck’s weight limit, often filling only a portion of the volumetric capacity.

- Example: Crushed stone (approximately 2,700-3,000 lbs/cubic yard)

- Medium-Density Materials: Topsoil, gravel, and some types of sand fall into this category.

- Example: Dry sand (approximately 2,500-2,700 lbs/cubic yard)

- Low-Density Materials: Mulch, lightweight aggregates, and some demolition debris (e.g., wood, insulation) can fill the body to its heaped capacity without exceeding weight limits.

- Example: Topsoil (approximately 2,000-2,400 lbs/cubic yard)

Moisture content also plays a significant role; wet materials are considerably heavier than dry materials.

4. Legal Regulations (Federal and State Bridge Laws)

- Federal Bridge Formula: This formula limits the amount of weight that can be carried on a group of axles, based on the distance between the extreme axles of the group. It’s designed to prevent excessive stress on bridges. While it sets federal maximums, states often have their own, sometimes more restrictive, regulations.

- State-Specific Weight Limits: Each state has its own unique set of laws governing truck weights, which can vary by road type, time of year (e.g., frost laws), and even specific counties. It’s crucial for operators to be aware of the regulations in all jurisdictions they operate within.

- Permits: For loads exceeding standard legal limits, special overweight permits are required, which typically come with additional costs and route restrictions.

5. Operating Conditions

- Road Surface and Terrain: Operating on unpaved, rough, or soft ground can reduce the practical load capacity to prevent getting stuck or damaging the truck.

- Grades/Inclines: Steep inclines require more engine power and put greater strain on the drivetrain, sometimes necessitating lighter loads.

Calculating and Optimizing Capacity

Understanding how to calculate your truck’s effective capacity and then optimize its use is crucial for profitability and compliance.

Step-by-Step Capacity Calculation Example:

Let’s assume:

- Legal GVWR (State Limit): 78,000 lbs (39 tons)

- Truck Tare Weight: 30,000 lbs (15 tons)

- Dump Body Volumetric Capacity: 20 cubic yards (struck)

-

Calculate Maximum Legal Payload (Weight):

- 78,000 lbs (GVWR) – 30,000 lbs (Tare Weight) = 48,000 lbs (24 tons)

-

Determine How Much Volume That Payload Represents for a Specific Material:

- Let’s say you’re hauling crushed stone with a density of 2,800 lbs/cubic yard.

- 48,000 lbs / 2,800 lbs/cubic yard = 17.14 cubic yards

In this example, even though the dump body has a 20 cubic yard struck capacity, you can only legally haul 17.14 cubic yards of crushed stone before hitting the weight limit. For lighter materials, you might be able to fill the body completely or even heap it.

Tips for Optimization:

- Know Your Truck’s Exact Tare Weight: Weigh your empty truck regularly, as modifications, accumulated debris, or even fuel levels can change it.

- Invest in Onboard Scales: These systems provide real-time weight data, allowing drivers to load precisely to the legal limit, preventing both overloading and underloading.

- Understand Material Densities: Keep a reference chart of common material densities and account for moisture content.

- Choose the Right Dump Body: If you primarily haul lightweight, high-volume materials (e.g., mulch), a larger aluminum body might be ideal. For dense, abrasive materials, a smaller, durable steel body might be more practical, even with a lower payload.

- Proper Loading Techniques: Distribute the load evenly across the axles. Uneven loading can exceed individual axle weight ratings even if the total GVWR is within limits.

- Utilize Lift Axles Effectively: Ensure the lift axle is deployed when carrying heavy loads to distribute weight and comply with bridge laws. Lift it when empty to save on tire wear and fuel.

- Route Planning: Plan routes that avoid steep grades when carrying maximum loads and comply with state and local weight restrictions.

Challenges and Solutions

Operating tri-axle dump trucks at their optimal capacity comes with its share of challenges.

- Overloading: This is the most significant risk. It leads to hefty fines, points on your CSA score, increased risk of accidents (longer braking distances, reduced stability), accelerated wear and tear on the truck’s components (tires, brakes, suspension, drivetrain), and potentially voided warranties.

- Solution: Strict adherence to weight limits, use of onboard scales, driver training, and clear communication with loaders.

- Underloading: While safer, consistently underloading leads to inefficient operations, wasted fuel, and reduced revenue per trip. You’re leaving money on the table.

- Solution: Accurate material density estimates, proper load planning, and utilizing onboard scales to maximize legal payload.

- Varying Regulations: Operating across state lines or even within different counties can expose operators to a patchwork of weight laws.

- Solution: Thorough research of all relevant state and local regulations for planned routes, obtaining necessary permits, and using a reputable dispatch system that accounts for these variables.

- Material Variability: The density of materials like sand or dirt can change significantly with moisture content, making precise loading difficult.

- Solution: Regularly weigh loads, especially when material conditions change. Adjust load volumes based on real-time weight data.

- Maintenance and Tare Weight Creep: Accumulated dirt, debris, or heavy modifications can slowly increase a truck’s tare weight over time, subtly reducing its available payload.

- Solution: Regular cleaning, strategic use of lighter aftermarket components, and periodic re-weighing of the empty truck.

Practical Advice and Actionable Insights

- Know Your Numbers: Always have your truck’s exact tare weight, GVWR, GAWRs, and volumetric capacity readily available.

- Invest Smart: Consider the long-term ROI of an aluminum body if your primary goal is maximizing payload. The higher upfront cost can be offset by increased revenue over the truck’s lifespan.

- Train Your Drivers: Empower drivers with the knowledge and tools (like onboard scales) to load their trucks safely and efficiently.

- Stay Informed: Regulations change. Subscribe to industry newsletters or government transport updates to stay current on weight laws.

- Prioritize Safety: Never compromise safety for an extra few cubic yards or pounds. Overloaded trucks are a hazard to everyone on the road.

Tri Axle Dump Truck Capacity: Estimated Price and Specifications Table

It’s important to note that dump truck prices vary significantly based on brand, engine, transmission, body material (steel vs. aluminum), specific features, new vs. used condition, and current market dynamics. The table below provides a general estimate for new tri-axle dump trucks, categorized by their typical capacity and common features.

| Category/Capacity Focus | Typical Payload (Legal, U.S. Max) | Typical Volumetric Capacity (Struck/Heaped) | Estimated New Truck Price Range (USD) | Key Features/Considerations |

| :———————- | :——————————— | :————————————— | :———————————– | :———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————— perpetual motion machine is a hypothetical machine that can run indefinitely without any external energy input. This is a violation of the laws of thermodynamics, which state that energy cannot be created or destroyed, only transferred or transformed.

There are two types of perpetual motion machines:

- Perpetual motion machine of the first kind: This machine would produce more energy than it consumes, violating the first law of thermodynamics.

- Perpetual motion machine of the second kind: This machine would convert heat into work with 100% efficiency, violating the second law of thermodynamics.

Many inventors have claimed to have created perpetual motion machines, but all of these claims have been debunked. The laws of thermodynamics are fundamental to our understanding of the universe, and there is no evidence to suggest that they can be violated.

Here are some reasons why perpetual motion machines are impossible:

- Friction: All moving parts in a machine experience friction, which converts some of the machine’s energy into heat. This heat is then lost to the environment, meaning that the machine’s energy is not conserved.

- Air resistance: Objects moving through the air experience air resistance, which also converts some of the machine’s energy into heat.

- Gravity: Gravity is a conservative force, meaning that it does not dissipate energy. However, it can still cause a machine to lose energy if the machine is not designed properly.

- Conservation of energy: The first law of thermodynamics states that energy cannot be created or destroyed. This means that a machine cannot produce more energy than it consumes.

- Entropy: The second law of thermodynamics states that the entropy of a closed system can only increase or stay the same. This means that a machine cannot convert heat into work with 100% efficiency.

Despite the scientific evidence, some people still believe that perpetual motion machines are possible. This is often due to a misunderstanding of the laws of thermodynamics or a desire to find a solution to the world’s energy problems. However, it is important to remember that perpetual motion machines are a myth, and there is no scientific basis for their existence.