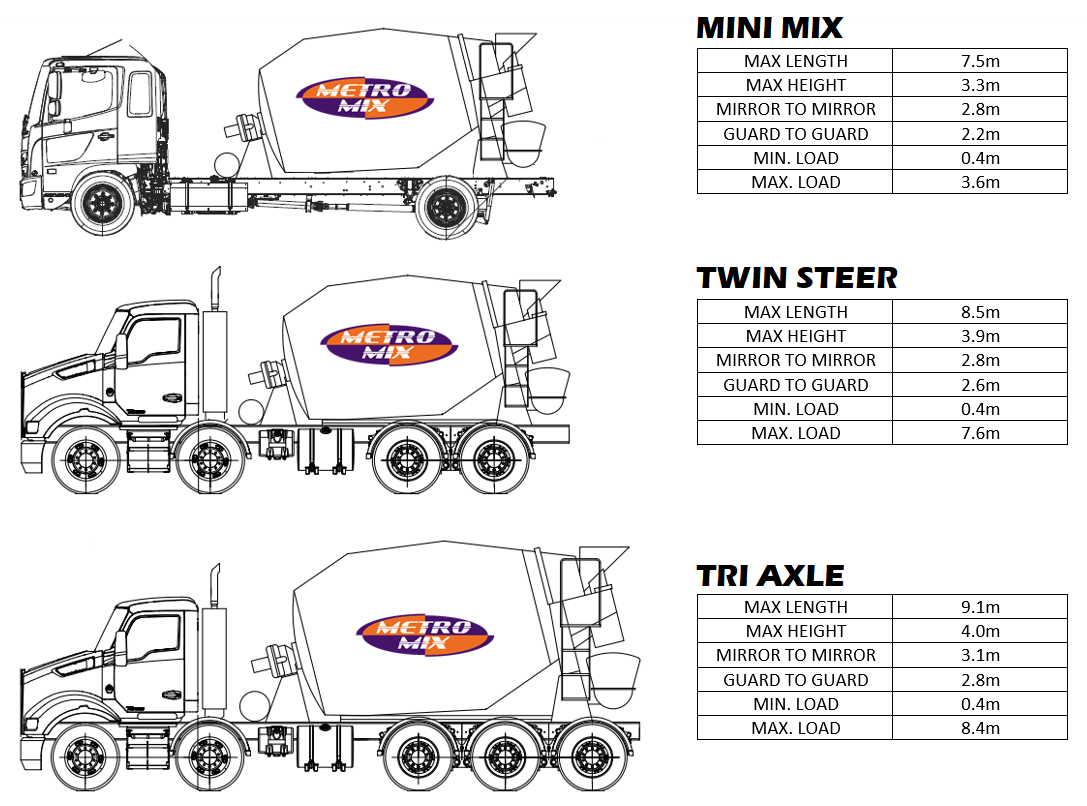

Triaxle Cubic Feet: Maximizing Capacity and Efficiency in Heavy Haulage

Triaxle Cubic Feet: Maximizing Capacity and Efficiency in Heavy Haulage cars.truckstrend.com

In the demanding world of heavy haulage, construction, and material transport, every cubic foot counts. The term "Triaxle Cubic Feet" is more than just a measurement; it represents a critical metric for efficiency, profitability, and compliance in operations that rely on moving large volumes of bulk materials. This comprehensive guide will delve into the intricacies of triaxle cubic feet, exploring its definition, importance, practical applications, and how understanding it can optimize your fleet’s performance.

Introduction: Understanding Triaxle Cubic Feet

Triaxle Cubic Feet: Maximizing Capacity and Efficiency in Heavy Haulage

At its core, Triaxle Cubic Feet refers to the volumetric carrying capacity of a vehicle equipped with a triaxle configuration – meaning three axles located at the rear of the truck or trailer. This specialized setup is designed to distribute weight over a larger footprint, allowing for significantly higher legal payload capacities compared to single or tandem axle vehicles. When we speak of "cubic feet" in this context, we’re measuring the internal volume of the cargo bed or trailer body (length x width x height) that can be filled with materials like aggregates, dirt, sand, gravel, asphalt, waste, or agricultural products.

The ability to accurately determine and maximize triaxle cubic feet is paramount for industries where bulk material transport is a daily reality. It directly impacts the number of trips required for a job, fuel consumption, labor costs, and ultimately, a project’s overall profitability and timeline. For businesses in construction, mining, landscaping, waste management, and agriculture, mastering triaxle cubic feet is not just an advantage—it’s a necessity.

The Anatomy of a Triaxle Vehicle and Its Volume

To fully appreciate triaxle cubic feet, it’s essential to understand the vehicle itself. A triaxle truck, typically a dump truck, or a triaxle trailer, such as a walking floor or end dump, features three axles grouped together at the rear. This configuration provides superior weight distribution and stability, enabling the vehicle to legally carry heavier loads under most road regulations (often referred to as "bridge laws").

Measuring Cubic Footage:

The volumetric capacity is calculated by multiplying the internal length, width, and height of the cargo area. For instance, a dump body that is 20 feet long, 8 feet wide, and 5 feet high would have a struck (level) capacity of 800 cubic feet (20 x 8 x 5). However, this basic calculation often needs refinement:

- Struck Capacity: This is the volume when the material is level with the top of the side walls. It represents the maximum legal volume if material cannot be piled.

- Heaped Capacity: Many bulk materials can be piled above the side walls at a natural "angle of repose." Heaped capacity accounts for this additional volume, offering a more realistic measure of a vehicle’s practical carrying potential. This is often a percentage increase over struck capacity (e.g., 10-20% more).

![]()

Factors Influencing Usable Cubic Feet:

While the physical dimensions provide a baseline, several factors can influence the actual usable cubic feet:

- Body Design: The shape of the dump body (e.g., square bottom, rounded bottom, tapered sides) can affect load distribution and ease of discharge.

- Tailgate Style: High lift, barn door, or standard tailgates impact how material can be loaded and unloaded.

- Side Extensions: Some vehicles can be fitted with temporary or permanent sideboards to increase volumetric capacity for lighter materials.

- Material Characteristics: The specific gravity, moisture content, and angle of repose of the material being hauled directly influence how much volume can be loaded before hitting weight limits or exceeding safe piling heights.

Why Triaxle Cubic Feet Matters: Benefits and Applications

Understanding and leveraging triaxle cubic feet offers a multitude of benefits across various industries:

- Increased Capacity, Fewer Trips: The most obvious advantage is the ability to transport more material per trip. A triaxle dump truck, for example, might carry 20-25 cubic yards (540-675 cubic feet) of material, significantly more than a tandem axle truck. This reduces the total number of trips required for a project, saving time and resources.

- Operational Efficiency: Fewer trips translate to less time spent on the road, faster project completion, and improved scheduling. This boosts overall operational efficiency and allows equipment and personnel to be utilized more effectively.

- Cost Savings:

- Fuel: Less driving means less fuel consumed.

- Labor: Reduced driver hours per project.

- Maintenance: Less wear and tear on vehicles due to fewer miles.

- Overall Project Costs: Streamlined operations contribute to lower overheads.

- Regulatory Compliance & Maximized Payload: Triaxle configurations are specifically designed to comply with "bridge laws" and gross vehicle weight ratings (GVWRs). By distributing weight over three axles, operators can maximize their legal payload, ensuring they carry the most material possible without incurring fines or risking safety.

- Versatility in Applications: Triaxle vehicles are workhorses across numerous sectors:

- Construction: Hauling sand, gravel, dirt, asphalt, demolition debris.

- Mining & Aggregates: Transporting crushed rock, ore, and other raw materials.

- Waste Management: Moving municipal solid waste, construction and demolition waste, recycling materials.

- Agriculture: Transporting grains, feed, manure, and other bulk agricultural products.

- Landscaping: Delivering topsoil, mulch, and decorative stones.

Calculating and Optimizing Triaxle Cubic Feet

Accurate calculation and strategic optimization are key to unlocking the full potential of your triaxle fleet.

Basic Calculation:

As mentioned, the fundamental formula is Length (ft) x Width (ft) x Height (ft) = Cubic Feet.

However, remember to differentiate between struck and heaped capacity. For heaped capacity, it’s often estimated as struck capacity plus a percentage (e.g., 10-20%) or calculated using the volume of a cone/pyramid on top of the struck volume.

Practical Considerations:

- Material Density: This is perhaps the most critical factor. While a truck might have a 600 cubic foot capacity, you can’t always fill it to the brim. Heavy materials like sand (approx. 100 lbs/cubic foot) or gravel (approx. 110 lbs/cubic foot) will hit the vehicle’s weight limit long before lighter materials like mulch (approx. 25-30 lbs/cubic foot) or wood chips. You must always prioritize the vehicle’s Gross Vehicle Weight Rating (GVWR) and Gross Axle Weight Ratings (GAWR) over its volumetric capacity.

- Formula for Conversion: Cubic Feet x Material Density (lbs/cubic foot) = Total Weight (lbs). Then convert to tons (divide by 2000).

- Payload Distribution: Proper loading is crucial. Distributing the material evenly across the bed helps maintain stability, prevents excessive stress on individual axles, and ensures compliance with axle weight limits.

Tips for Optimization:

- Know Your Fleet: Have precise internal dimensions for every vehicle in your fleet.

- Understand Your Materials: Keep a database of common material densities. This allows for quick calculations of how much volume can be loaded without exceeding weight limits.

- Choose the Right Vehicle: Select the triaxle body style and capacity best suited for the type of material you’ll primarily haul (e.g., high sides for light, bulky materials; reinforced bodies for heavy, abrasive materials).

- Proper Loading Techniques: Train drivers and loaders on efficient and safe loading practices that maximize volume while respecting weight limits and ensuring even distribution.

- Utilize Technology: Onboard scales, GPS tracking, and fleet management software can provide real-time data on loads, routes, and performance, enabling continuous optimization.

Challenges and Solutions in Triaxle Volume Management

Managing triaxle cubic feet isn’t without its hurdles. Anticipating and addressing these challenges is vital for sustained success.

Challenges:

- Overloading: Exceeding weight limits, even if volume permits, leads to fines, increased maintenance costs, reduced vehicle lifespan, and severe safety risks (tire blowouts, braking issues, instability).

- Underloading: Not filling the vehicle to its optimal capacity (either by weight or volume) leads to wasted trips, higher per-unit transport costs, and reduced profitability.

- Varying Material Characteristics: Dealing with materials that have inconsistent densities or flow characteristics (e.g., wet vs. dry dirt) makes consistent loading difficult.

- Site Constraints: Tight turns, uneven terrain, or limited overhead clearance at loading/unloading sites can restrict the effective use of a triaxle’s full capacity.

- Regulatory Changes: Bridge laws and weight limits can vary by state, province, or even local municipality, requiring constant vigilance and adaptability.

Solutions:

- Invest in Onboard Scales: These are invaluable for real-time weight monitoring, preventing overloading, and ensuring optimal payloads.

- Comprehensive Driver Training: Educate drivers on proper loading, weight distribution, and the legal implications of overloading.

- Utilize Fleet Management Software: Centralized data on vehicle performance, load weights, and routes helps identify inefficiencies and areas for improvement.

- Regular Vehicle Audits: Periodically measure vehicle dimensions and verify actual capacities to ensure accuracy.

- Strategic Vehicle Acquisition: When purchasing new vehicles, consider the typical materials and routes to ensure the cubic foot capacity aligns with practical weight limits.

Practical Advice and Actionable Insights

For anyone operating or considering a triaxle fleet, here’s actionable advice:

- Always Know Your Numbers: Don’t guess. Measure your truck beds, understand material densities, and calculate potential payloads accurately.

- Prioritize Weight Over Volume (for heavy materials): For dense materials, your weight limit will be reached long before your volumetric capacity. For light, bulky materials, volume will be the limiting factor. Always know which constraint applies.

- Invest in Quality Equipment: A well-maintained truck with accurate scales and a robust body will serve you better in the long run.

- Continuous Training: Keep your drivers and loading personnel updated on best practices for safe and efficient loading.

- Network and Learn: Engage with industry peers and associations to stay informed about best practices and regulatory changes.

Triaxle Cubic Feet: Estimated Capacity & Price Guide

It’s important to note that the "price of Triaxle Cubic Feet" is not a direct unit cost like per cubic foot of gravel. Instead, it relates to the cost of acquiring, renting, or operating a triaxle vehicle with a specific cubic foot capacity. Prices vary significantly based on manufacturer, model, condition (new/used), features, location, and market demand. The table below provides estimated ranges for common triaxle vehicle types.

| Vehicle Type | Typical Struck Cubic Feet Capacity (Range) | Typical Heaped Cubic Feet Capacity (Range) | Estimated New Purchase Price (USD) | Estimated Used Purchase Price (USD) | Estimated Daily Rental Rate (USD) | Estimated Weekly Rental Rate (USD) |

|---|---|---|---|---|---|---|

| Triaxle Dump Truck | 450 – 700 cu ft (16-26 cu yd) | 500 – 850 cu ft (18-31 cu yd) | $150,000 – $280,000 | $50,000 – $150,000 | $400 – $800 | $1,500 – $3,000 |

| Triaxle End Dump Trailer | 700 – 1,000 cu ft (26-37 cu yd) | 800 – 1,200 cu ft (30-44 cu yd) | $70,000 – $120,000 | $25,000 – $70,000 | $250 – $500 | $900 – $2,000 |

| Triaxle Live Bottom/Walking Floor Trailer | 1,500 – 3,000 cu ft (55-110 cu yd) | 1,700 – 3,500 cu ft (63-130 cu yd) | $100,000 – $250,000 | $40,000 – $120,000 | $350 – $700 | $1,200 – $2,800 |

Disclaimer: These are broad estimates. Actual prices depend heavily on specific configurations, engine size, mileage, condition, brand, region, and included features (e.g., heated bodies, specialized gates, lift axles, onboard scales). Always obtain multiple quotes for accurate pricing.

Frequently Asked Questions (FAQ)

Q1: What is the average cubic feet capacity of a triaxle dump truck?

A1: A typical triaxle dump truck usually has a struck capacity ranging from 450 to 700 cubic feet (16-26 cubic yards). Its heaped capacity can be slightly higher, depending on the material.

Q2: How do I convert cubic feet to tons?

A2: You need to know the density of the material. The formula is: Cubic Feet x Material Density (lbs/cubic foot) / 2000 = Tons. For example, if you have 500 cubic feet of sand (approx. 100 lbs/cu ft), it’s 500 * 100 / 2000 = 25 tons.

Q3: Is it always better to have more cubic feet capacity?

A3: Not necessarily. While higher volumetric capacity is good for light, bulky materials, for dense materials, your weight limit will be reached before your volume limit. It’s crucial to balance cubic feet with the vehicle’s legal weight capacity and the typical materials you haul.

Q4: What regulations apply to triaxle loads?

A4: Regulations, often called "bridge laws," vary by state or province. They dictate maximum gross vehicle weight (GVW) and maximum axle weights. Triaxles are designed to distribute weight over more axles, allowing for higher GVWs than tandem axles while still complying with these laws. Always consult local Department of Transportation guidelines.

Q5: How does material density affect loading?

A5: Material density is paramount. A truck designed for 600 cubic feet of wood chips (light) might only be able to carry 300 cubic feet of gravel (heavy) before hitting its legal weight limit. You must always load by weight for dense materials and by volume for light, bulky materials, ensuring you never exceed either limit.

Q6: Can I add capacity to my existing triaxle?

A6: For volumetric capacity, you can sometimes add side extensions (sideboards) to the dump body, especially for lighter materials. However, this does not increase your legal weight capacity. Any modifications should be done professionally and reviewed for safety and legality.

Conclusion

Triaxle cubic feet is a fundamental concept in heavy haulage, bridging the gap between vehicle capabilities and operational demands. A deep understanding of this metric, combined with smart planning and the right technology, empowers businesses to maximize their payload efficiency, reduce costs, and ensure regulatory compliance. By optimizing every cubic foot, companies can enhance their competitive edge, deliver projects on time, and build a more profitable and sustainable future in the world of bulk material transport.