What Are The Different Names For Lorry Sections: A Comprehensive Guide to Heavy Vehicle Anatomy

What Are The Different Names For Lorry Sections: A Comprehensive Guide to Heavy Vehicle Anatomy cars.truckstrend.com

The world of logistics and transportation relies heavily on a colossal machine known variously as a lorry, truck, or heavy goods vehicle (HGV). Far from being a simple box on wheels, a modern lorry is a complex marvel of engineering, comprising numerous specialized sections, each with its own crucial function and, often, a specific name. Understanding these different sections is not merely an academic exercise; it’s fundamental for drivers, mechanics, logistics managers, and anyone involved in the heavy transport industry. Precise terminology ensures clear communication, facilitates efficient maintenance, enhances safety, and aids in legal compliance and purchasing decisions.

This comprehensive guide will dissect the anatomy of a lorry, breaking it down into its core components and exploring the diverse names and functions associated with each section.

What Are The Different Names For Lorry Sections: A Comprehensive Guide to Heavy Vehicle Anatomy

1. The Cab: The Command Center

Often considered the face of the lorry, the cab is the enclosed compartment where the driver operates the vehicle. It’s the driver’s office, and for long-haul journeys, their home away from home.

- Sleeper Cab / Bunk: This is a common feature on long-distance lorries, providing a sleeping area behind the driver’s seat. It often includes a bunk, storage, and sometimes a small table or refrigerator, enabling drivers to rest without leaving their vehicle.

- Day Cab: In contrast, a day cab is designed for shorter hauls or local deliveries and does not include a sleeping compartment. It’s typically more compact.

- Controls & Dashboard: This encompasses the steering wheel, pedals (accelerator, brake, clutch), gear selector, and the instrument panel displaying vital information like speed, RPM, fuel levels, and warning lights. Modern cabs feature sophisticated infotainment systems and navigation aids.

- Seating: The driver’s seat is usually air-sprung and highly adjustable for comfort during long hours. A passenger seat may also be present.

- Windscreen / Windshield: The large front window providing the driver with forward visibility.

- Mirrors: Essential for safety, these include large side mirrors, often with additional convex mirrors to minimize blind spots.

Understanding the cab’s layout is crucial for driver comfort, ergonomics, and safe operation.

2. The Chassis: The Backbone of the Lorry

The chassis is the foundational structure of the lorry, akin to the skeleton of a human body. It supports the engine, cab, body, and all other components, bearing the entire weight of the vehicle and its cargo.

- Frame Rails: These are the primary longitudinal beams (usually made of high-strength steel) that run the length of the vehicle, forming the main structure of the chassis.

- Crossmembers: Shorter beams that connect and brace the frame rails, providing rigidity and stability.

- Suspension System: This vital system connects the axles to the chassis, absorbing shocks and vibrations from the road. Components include:

- Leaf Springs: Traditional multi-layered steel springs.

- Coil Springs: Spiraled metal springs, less common in heavy lorries.

- Airbags / Air Suspension: Air-filled rubber bags that provide a smoother ride and allow for adjustable ride height, often seen on modern lorries.

- Shock Absorbers / Dampers: Control the oscillation of the springs.

- Axles: Solid shafts connecting wheels, supporting weight, and transferring power.

- Front Axle: Typically a non-driven axle used for steering.

- Drive Axles: Rear axles that receive power from the engine to propel the lorry.

- Tag Axle / Pusher Axle: Additional non-driven axles placed behind or in front of the drive axles to distribute weight and increase carrying capacity, often liftable when not needed.

- Wheels & Tyres: The components that make contact with the road. Lorries typically have multiple wheels (e.g., 6, 8, 10, 12, or more) to distribute heavy loads.

- Braking System: Most lorries use air brakes, which rely on compressed air to operate. Components include air tanks, compressor, brake chambers, and brake drums/discs. Modern systems incorporate ABS (Anti-lock Braking System) and EBS (Electronic Braking System) for enhanced safety.

- Fuel Tank: A large reservoir for diesel fuel, often with capacities of hundreds of liters for extended range.

- Exhaust System: Directs exhaust gases away from the engine, often including components for emissions control like SCR (Selective Catalytic Reduction) and DPF (Diesel Particulate Filter).

The chassis is the workhorse, dictating the lorry’s load-carrying capacity, stability, and handling characteristics.

3. The Drivetrain: Powering the Beast

The drivetrain is the system responsible for transmitting power from the engine to the drive wheels, making the lorry move.

- Engine: The heart of the lorry, almost universally a large, powerful diesel engine. These come in various configurations (e.g., inline-6, V8) and are designed for high torque and fuel efficiency over long distances.

- Transmission / Gearbox: This component changes the gear ratio between the engine and the drive wheels, allowing the driver to select the appropriate power and speed for different conditions. Types include:

- Manual Transmission: Requires the driver to manually select gears using a clutch pedal and gear stick.

- Automatic Transmission: Automatically selects gears.

- Automated Manual Transmission (AMT): A hybrid system that uses an automatic clutch and gear shifting but retains the mechanical gears of a manual.

- Clutch: In manual and AMT systems, the clutch connects and disconnects the engine from the transmission, allowing for smooth gear changes.

- Propeller Shaft / Drive Shaft: A rotating shaft that transmits power from the transmission to the differential(s) on the drive axles.

- Differential: A gear assembly located within the axle housing that allows the wheels on the same axle to rotate at different speeds, which is essential for turning corners without skidding.

The drivetrain’s efficiency and robustness are critical for the lorry’s performance and operational costs.

4. The Body/Trailer: The Payload Carrier

This is arguably the most diverse section, as it’s specifically designed to carry different types of cargo. The term "body" usually refers to the cargo section of a rigid lorry (a single, non-articulated unit), while "trailer" refers to the separate cargo unit pulled by a tractor unit (the front part of an articulated lorry).

Common Body/Trailer Types and Their Names:

- Flatbed: An open platform with no sides or roof, ideal for oversized or irregularly shaped cargo that needs to be secured with straps or chains.

- Curtainsider / Tautliner: Features a rigid roof and rear doors, but with flexible PVC curtains along the sides that can be pulled back for easy side loading and unloading. Extremely versatile.

- Box Body / Dry Van: A fully enclosed, rigid box structure, protecting cargo from weather and theft. Used for general freight that doesn’t require temperature control.

- Refrigerated Trailer / Reefer: A thermally insulated box body equipped with a refrigeration unit to maintain specific temperatures, used for perishable goods like food, pharmaceuticals, or flowers.

- Tanker: A cylindrical or elliptical vessel designed to transport liquids (e.g., fuel, chemicals, milk) or gases.

- Tipper / Dump Truck: Features an open-top body that can be hydraulically raised to "tip" or dump loose materials like sand, gravel, or demolition waste.

- Low Loader / Lowboy: A trailer with a very low deck height, designed for transporting extremely tall, heavy, or oversized machinery (e.g., excavators, wind turbine components).

- Skeletal Trailer: A minimalist frame trailer designed specifically to transport standard shipping containers.

- Car Transporter: Multi-level trailers with ramps and securing mechanisms for transporting multiple cars.

- Drawbar Trailer / Full Trailer: A trailer with its own front axle and drawbar, which is hitched to a rigid lorry or another drawbar trailer, forming a "road train."

- Fifth Wheel Coupling (on Tractor Unit): The heavy-duty coupling device located behind the cab of a tractor unit, shaped like a horseshoe, onto which a semi-trailer is hitched.

- Kingpin (on Semi-trailer): A large, vertical steel pin located on the underside of the front of a semi-trailer, which locks into the fifth wheel coupling of the tractor unit.

- Landing Gear / Jacks: Retractable legs at the front of a semi-trailer that support it when it is uncoupled from the tractor unit.

The choice of body or trailer type is dictated entirely by the nature of the cargo and the logistics requirements.

5. Ancillary Systems and External Components

Beyond the major sections, numerous smaller but equally critical components contribute to the lorry’s functionality, safety, and operation.

- Lights: A comprehensive array including headlights (high/low beam), tail lights, brake lights, indicator lights (turn signals), marker lights (side lights), fog lights, and often additional work lights or spotlights.

- Mudguards / Fenders: Located over the wheels to prevent mud, water, and debris from being thrown up by the tyres.

- Air Tanks: Reservoirs for compressed air used by the braking system, suspension, and other pneumatic accessories.

- Battery Box: An enclosed compartment housing the vehicle’s large batteries, typically 24-volt systems.

- Toolbox: Storage for essential tools, spare parts, and equipment.

- Walkways / Catwalks: Non-slip platforms and steps providing safe access around the chassis, particularly around the fifth wheel.

- Hydraulic Systems: Used for operations like lifting tipper bodies, operating cranes mounted on the lorry, or extending ramps on low loaders.

- Fuel Filler Cap/Neck: Where fuel is added to the tank.

6. Regional Terminology and Slang

The terminology for lorries and their sections can vary significantly across different English-speaking regions, particularly between the UK/Commonwealth countries and North America.

- Lorry (UK/Commonwealth) vs. Truck (US/Canada): The most fundamental difference.

- Articulated Lorry / Artic (UK) vs. Semi-truck / Tractor-trailer (US): Refers to a lorry with a separate tractor unit and semi-trailer.

- Rigid Lorry (UK) vs. Straight Truck (US): Refers to a single, non-articulated lorry where the cab and cargo body are on one continuous chassis.

- Juggernaut (colloquial UK): A more informal term for a very large lorry.

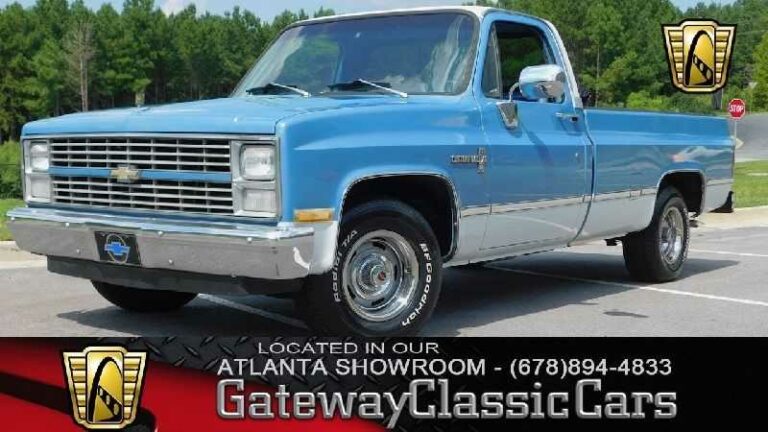

- Cab-over / Forward Control (UK): Where the cab sits directly over the engine.

- Conventional / Bonneted (US): Where the engine is in front of the cab, under a bonnet (hood).

- Lorry Driver (UK) vs. Trucker (US): The common terms for the operator.

- Road Train (Australia): A combination of multiple trailers pulled by a single prime mover.

Why Knowing These Names Matters: Practical Advice and Actionable Insights

- Maintenance & Repair: When a component fails, being able to accurately describe the "propeller shaft" rather than "the long spinny bit under the truck" saves time, money, and frustration for both the driver and the mechanic.

- Safety Inspections: Drivers perform daily "walk-around checks" or "pre-trip inspections." Knowing the names of components like "air lines," "kingpin," or "landing gear" ensures a thorough and effective inspection, identifying potential hazards before they lead to accidents.

- Operational Efficiency: Understanding how different sections interact helps in optimizing load distribution, managing trailer coupling/uncoupling, and navigating challenging terrains.

- Purchasing & Sales: Whether buying a new lorry or selling a used trailer, precise terminology allows for accurate specification and valuation.

- Legal Compliance: Regulations often refer to specific vehicle sections (e.g., axle weight limits, brake system requirements), making knowledge of these terms essential for compliance.

- Industry Communication: Speaking the common language of the industry fosters professionalism and clarity across the supply chain, from manufacturers to logistics planners to end-users.

Challenges and Tips

The sheer volume of terminology can be daunting, especially with regional variations.

Tip 1: Start with the main components (cab, chassis, engine, body/trailer) and then gradually learn the sub-components.

Tip 2: Use visual aids. Diagrams and actual lorries are excellent learning tools.

Tip 3: Pay attention during pre-trip inspections; consciously identify and name each part as you check it.

Tip 4: If you’re specializing (e.g., in tankers), focus on the specific terminology for that type of lorry.

Key Lorry Sections and Their Primary Functions

| Section Name | Primary Function | Key Components |

|---|---|---|

| Cab | Driver’s operating and resting compartment | Steering wheel, dashboard, seats, sleeper bunk (if present), windscreen, mirrors |

| Chassis | Structural foundation; supports all components | Frame rails, crossmembers, suspension system (springs, airbags, shocks), axles, wheels & tyres, brake system |

| Drivetrain | Transmits power from engine to wheels | Engine, transmission/gearbox, clutch, propeller shaft, differential |

| Body/Trailer | Carries the cargo | Flatbed, Curtainsider, Box Body, Reefer, Tanker, Tipper, Low Loader, Skeletal, Car Transporter |

| Coupling System | Connects tractor unit to semi-trailer | Fifth Wheel (tractor unit), Kingpin (semi-trailer), Landing Gear |

| Ancillary Systems | Supports overall operation and safety | Lights, mudguards, air tanks, battery box, toolbox, hydraulic systems |

Frequently Asked Questions (FAQ)

Q1: What’s the main difference between a "lorry" and a "truck"?

A1: The terms are largely interchangeable but depend on geographic location. "Lorry" is primarily used in the UK and Commonwealth countries, while "truck" is the standard term in North America (US and Canada).

Q2: What is an "articulated lorry"?

A2: An articulated lorry (or "semi-truck" in the US) is a vehicle combination consisting of two separate parts: a "tractor unit" (which contains the engine and cab) and a "semi-trailer" (the cargo-carrying unit) that is hitched to the tractor unit. This allows for greater flexibility, as different trailers can be swapped.

Q3: What is a "rigid lorry"?

A3: A rigid lorry (or "straight truck" in the US) is a single, continuous vehicle where the cab and the cargo body are permanently mounted on one chassis. It does not articulate or separate into two main parts.

Q4: Why are there so many different types of lorry bodies?

A4: The variety of lorry bodies reflects the diverse nature of goods transported. Each body type is specialized to safely and efficiently carry specific types of cargo, considering factors like temperature control, protection from elements, ease of loading/unloading, and the physical characteristics of the goods (e.g., liquid, bulk, oversized).

Q5: What is a "fifth wheel" and a "kingpin"?

A5: The "fifth wheel" is the large, horseshoe-shaped coupling device located on the back of a tractor unit. The "kingpin" is a large, vertical steel pin extending downwards from the front underside of a semi-trailer. The kingpin slots into the fifth wheel, creating a secure, pivotal connection that allows the tractor unit and trailer to turn independently.

Conclusion

The world of lorries is one of precision, power, and specialized design. Understanding the different names for lorry sections is more than just learning vocabulary; it’s about gaining a deeper appreciation for the engineering, safety, and operational intricacies of these vital machines. From the driver’s command center in the cab to the robust backbone of the chassis, and the diverse functions of various body types, each component plays a critical role. Mastering this terminology empowers drivers, mechanics, and logistics professionals to communicate effectively, ensure safety, optimize performance, and keep the wheels of global commerce turning smoothly.